Counterweight combined water tanks for pressure test of foundation tubular piles and pressure test method

A technology for combining water tanks and water tanks, which is applied in basic structure tests, basic structure engineering, construction, etc., and can solve problems such as accidents, damage to bottom water tanks, and load-bearing frame dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

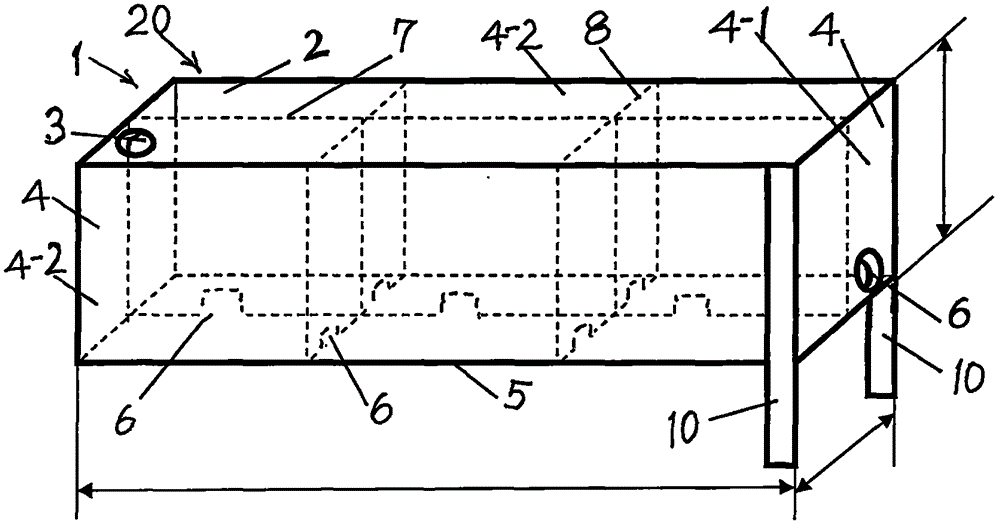

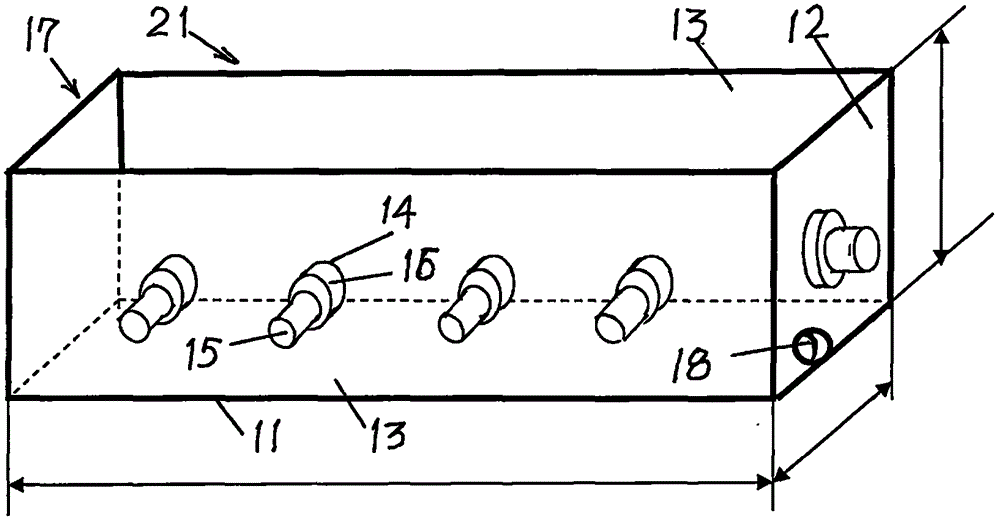

[0085] Embodiment 1, the two-layer combined water tank used in the foundation pipe pile for water tank pressure test

[0086] Such as figure 1 , 2 , 3, the used two-layer combined water tank of water tank pressure test foundation pipe pile, comprises bottom water tank 20 and upper water tank 21, and upper water tank 21 overlaps and places above bottom water tank 20;

[0087] [1], the structure of the bottom water tank 20: including a rectangular steel box 1 fixedly connected on six sides, one or more water inlet holes 3 are provided on the top plate 2 of the rectangular steel box 1, and on the side plate 4 of the rectangular steel box 1 One or more water outlet holes 6 are provided near the bottom plate 5; the side plate 4 of the rectangular steel box 1 includes two small side plates 4-1 on the opposite side, and two large side plates 4-1 on the opposite side. 2;

[0088] In the rectangular steel box 1, one or more long partitions 7 are fixedly connected between the two sma...

Embodiment 2

[0103] Embodiment 2, the three-layer combined water tank used in the foundation pipe pile for water tank pressure test

[0104] Such as figure 1 , 2 , 3, the three-layer combined water tank used for the foundation pipe pile of the water tank pressure test,

[0105] [1], same as embodiment 1;

[0106] [2], same as embodiment 1;

[0107] [3], same as embodiment 1;

[0108] [4], same as embodiment 1;

[0109] [5], same as embodiment 1;

[0110] [6], the upper strata water tank 21 external dimensions of small size are:

[0111] Box bottom plate 11, its external dimensions are: length 12.3 meters, width 2.7 meters;

[0112] The end face side panel 12 has the dimensions: 2.7 meters wide and 2.8 meters high;

[0113] Front side panel 13, its external dimensions are: length 12.3 meters, height 2.8 meters;

[0114] [7], the upper strata water tank 21 external dimensions of big size are:

[0115] Box bottom plate 11, its external dimensions are: length 12.6 meters, width 2.9 m...

Embodiment 3

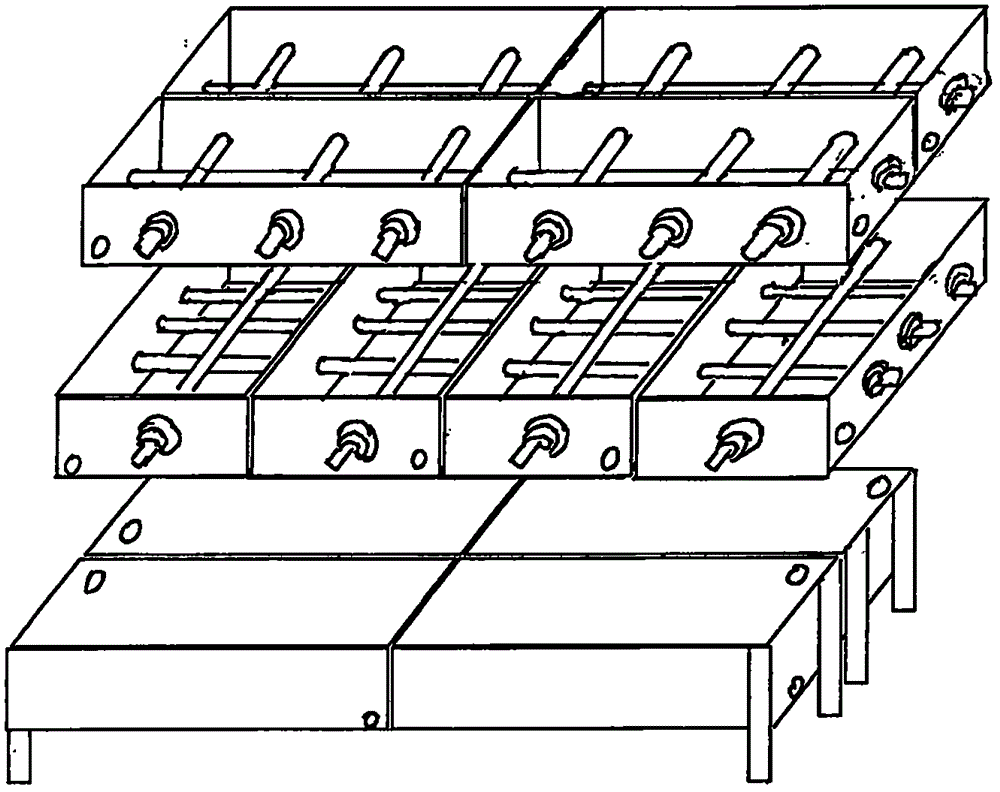

[0118] Embodiment 3, four bottom water tanks 20 " device " font arrangement type combined water tanks, the method of pressure test detection method for foundation pipe piles is as follows figure 1 , 2 , 3, 4, with four bottom water tanks 20 of embodiment 1 " device " font arrangement type combined water tank, to foundation pipe pile pressure test detection method, four bottom water tanks 20 of " device " font arrangement are pressed on foundation foundation On the pipe pile, the specific steps are as follows:

[0119] [1], Build pressure test and load-bearing combination device: place test pressure gauge 32 on the foundation pipe pile 31 to be tested, place concentrated pressure thick steel plate 33 on test pressure gauge 32, place component force on concentrated pressure thick steel plate 33 Bearing frame 34;

[0120] [2], Stacking the elevated strip piles for stably placing the water tank: use soil or building material solids on the ground on the opposite sides of the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com