Electrostatic spinning sprinkler in trapezoid wave array and electrostatic spinning device

An electrospinning and trapezoidal wave technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve uneven spinning, large difference in nozzle electric field, insufficient nozzle electric field to reach critical spinning value, etc. problem, to achieve the effect of small difference in electric field intensity and large electric field intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

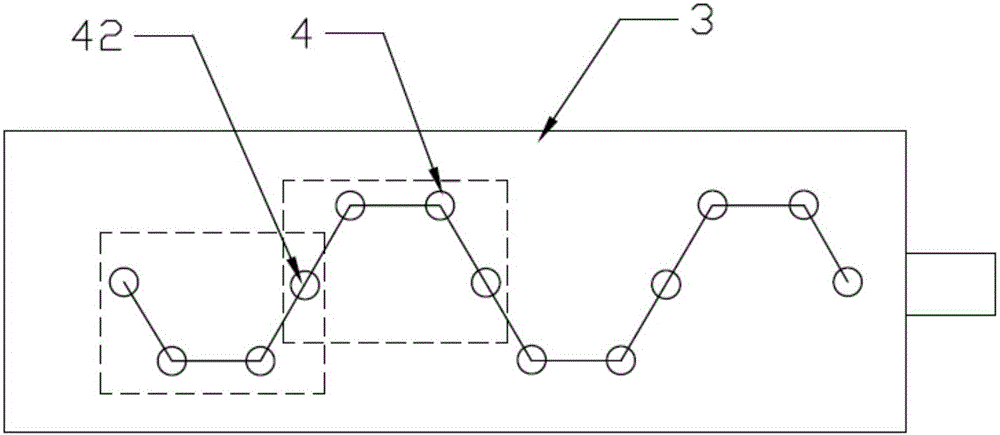

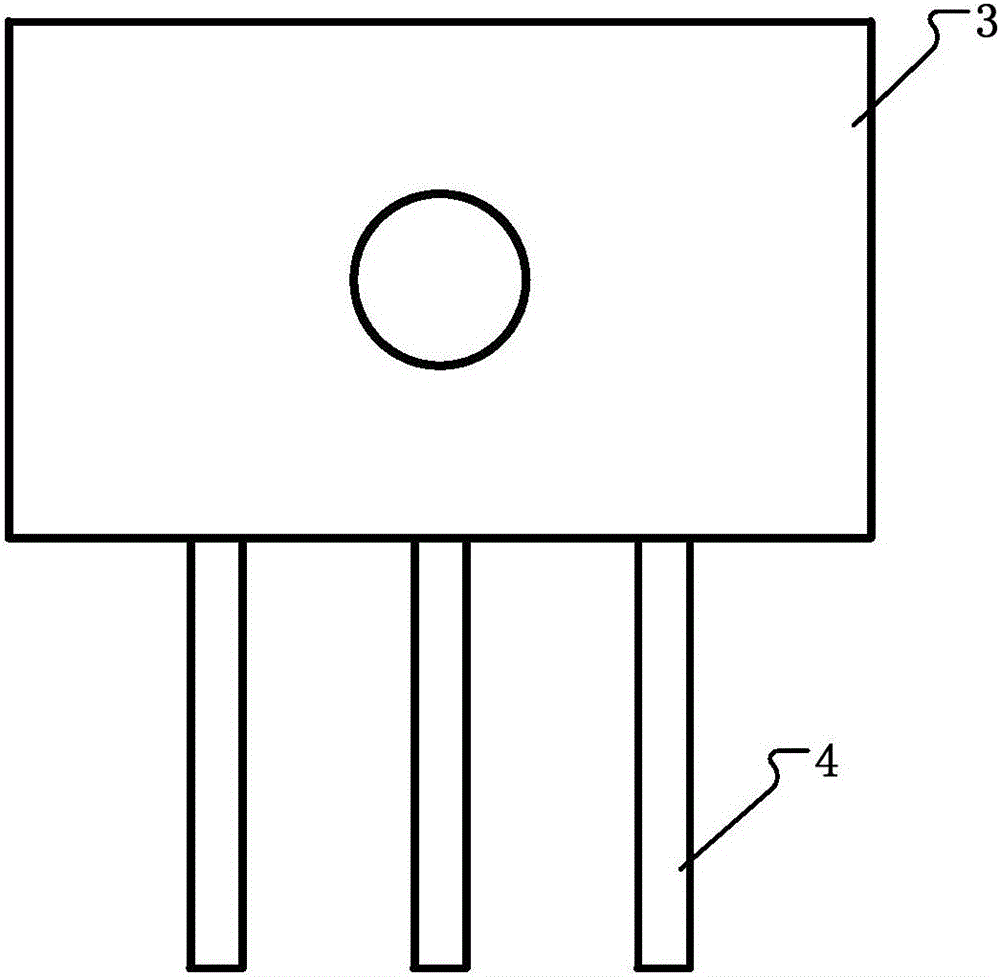

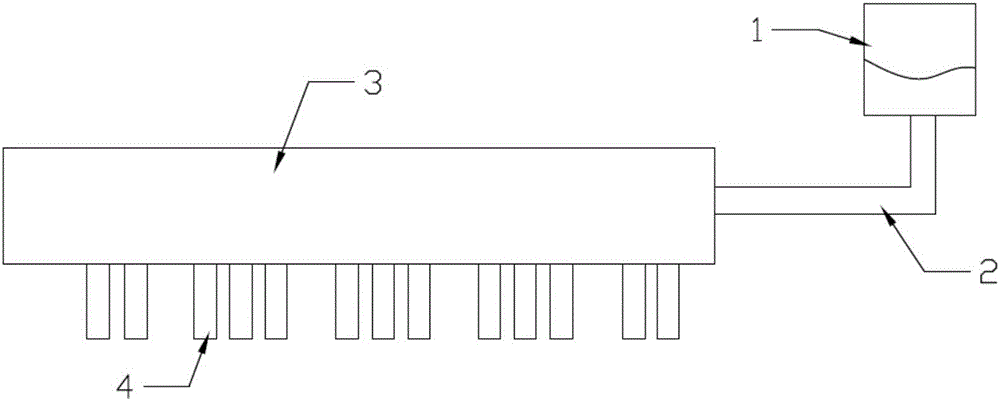

[0018] Such as figure 1 with figure 2 The electrospinning nozzle of the trapezoidal wave array shown includes a nozzle main body 3, and the nozzle main body 3 has a liquid outlet channel inside for introducing external spinning liquid. In addition, the nozzle main body 3 has an output plane and at least three sets of output structures are provided on the nozzle main body 3, and the output structures are used to collect and spray the spinning solution entering from the outlet channel for spinning.

[0019] In the embodiment, each group of output structures includes four nozzle holes opened on the output plane and needle nozzles 4 respectively connected to the nozzle holes. As shown in the drawings, the nozzle holes are not labeled, but those skilled in the art It is easy to understand that the spray hole and the needle nozzle 4 overlap. The end of the needle nozzle 4 away from the spray hole is a needle tip, and this needle nozzle 4 is a commonly used nozzle structure in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com