Straw continuous decomposition equipment

A straw and equipment technology, applied in the field of straw continuous decomposition equipment, can solve problems such as poor cooling effect, ineffective reuse of hot air, poor discharge of carbon powder, etc., and achieve the effect of improving the carbonization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

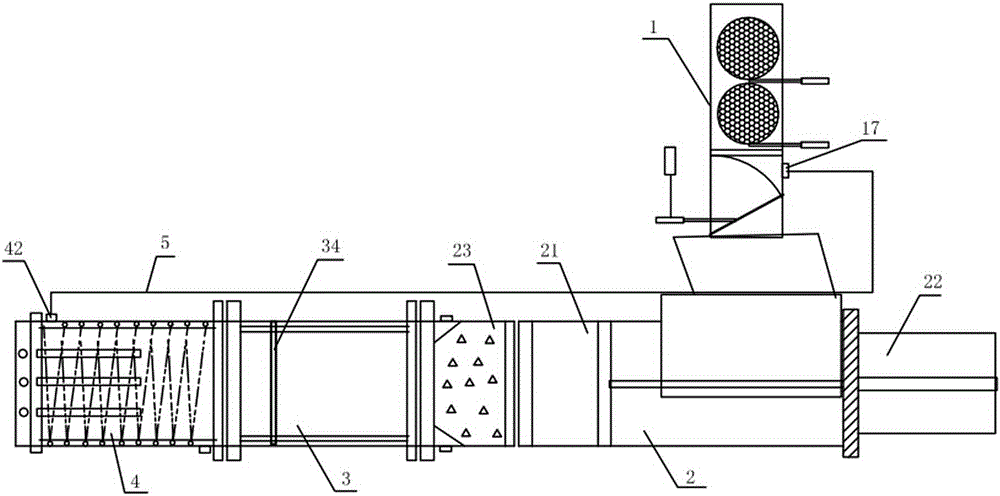

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

[0031] A straw continuous decomposition equipment, the equipment is mainly used in the decomposition of straw, it includes an air drying device 1, a propulsion device 2, a decomposition device 3 and a cooling device 4, the air drying device 1 dries the straw bundles and automatically falls into the propulsion device 2 Inside, the propelling device 2 is to push the fallen straw bales into the decomposition furnace 3 for decomposition, and the cooling device 4 cools the decomposed high-temperature straw charcoal (charcoal powder). The discharge port of the air-drying device 1 is connected with the feed port of the propulsion device 2, the discharge port of the propulsion device 2 is connected with the feed port of the decomposition device 3, and the discharge port of the decomposition device 3 is connected with the feed port of the cooling device 4 .

[0032] The air-drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com