Ultra-thin float glass production line tin bath protective gas intelligent control system

An intelligent control system and float glass technology, applied in the field of automatic control, can solve problems affecting the yield of ultra-thin glass and large content errors, so as to improve the safety production factor and ensure production safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

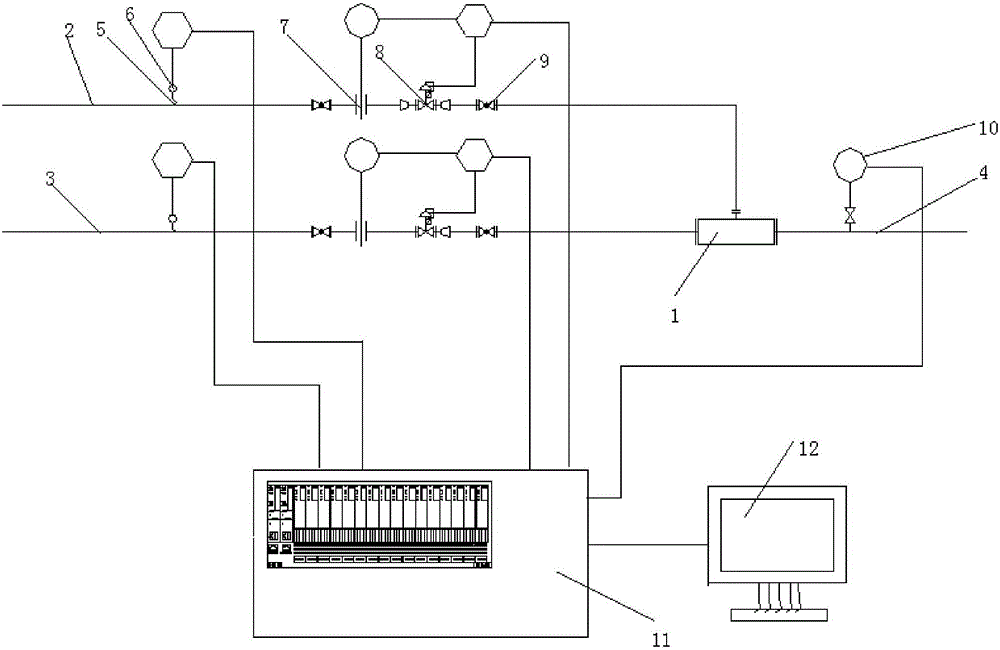

[0018] Referring to the accompanying drawings, the intelligent control system for the tin bath protection gas of the ultra-thin float glass production line includes a hydrogen supply pipeline 2 connected to the tin bath 1, an oxygen supply pipeline 3, a mixed gas circuit 4, a hydrogen supply pipeline 2, A pressure transmitter 5, a temperature sensor 6, a flow transmitter 7, an electric regulating valve 8, and a pneumatic shut-off valve 9 are installed in sequence on the oxygen supply pipeline 3, and a gas purity analyzer 10 is installed in the mixed gas circuit 4. Transmitter 5, temperature sensor 6, flow transmitter 7, electric regulating valve 8, pneumatic shut-off valve 9, and gas purity analyzer 10 are respectively connected to PLC controller 11, and PLC controller 11 is connected to DCS controller 12, and the pressure Transmitters and temperature sensors are externally connected to host computer stations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com