Safety carbon cover folding device

A carton and safety technology, applied in the field of safe carton folding cover device, can solve the problems of inconvenient production and maintenance, inconvenient fault handling, and existing safety, and achieve the effects of improving production safety, facilitating production and maintenance, and shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose, technical solution and beneficial effect of the invention clearer, a safe carton folding lid device of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

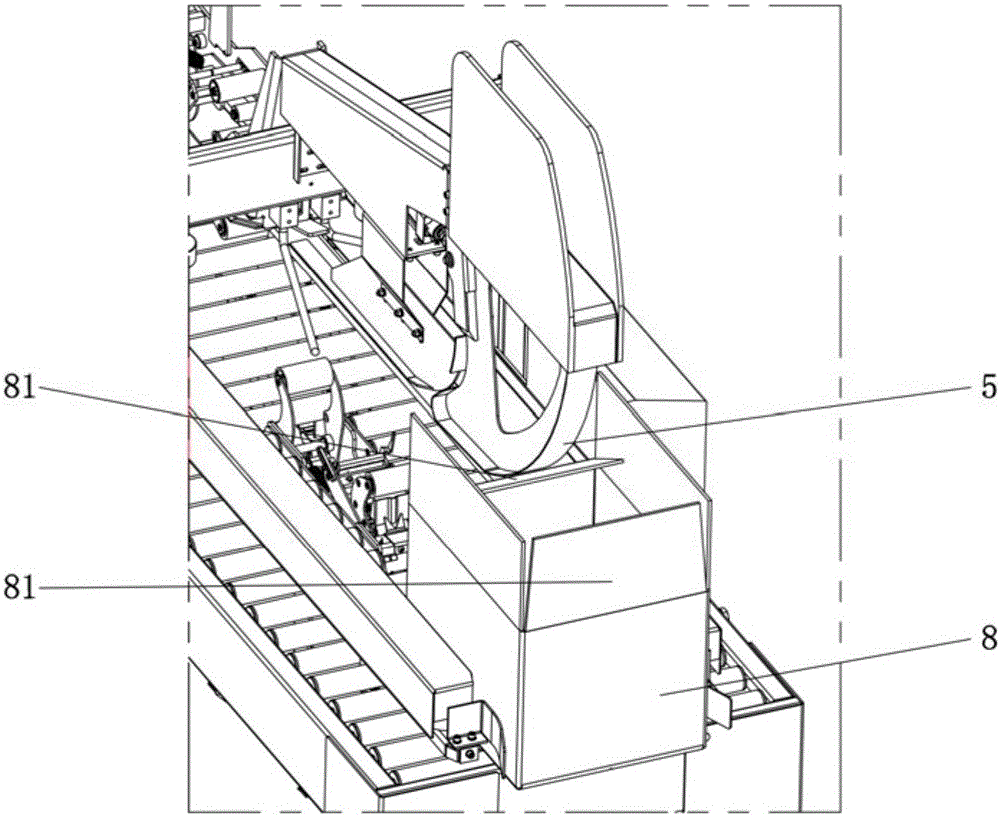

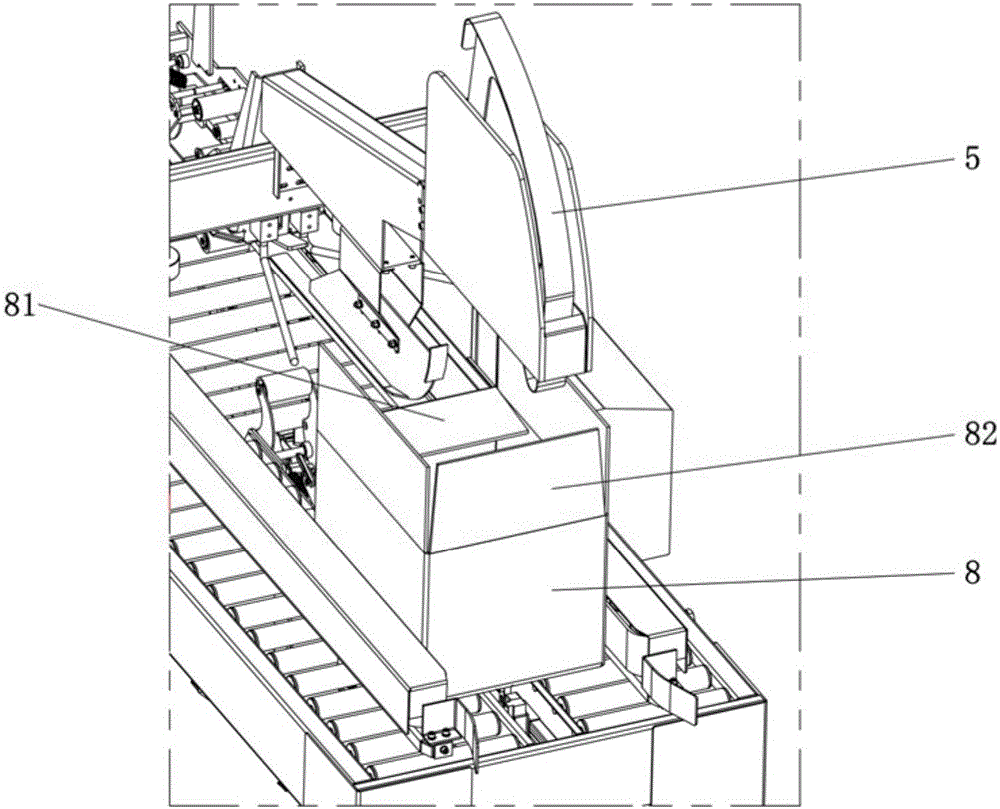

[0014] refer to figure 1 As shown, the safe carton folding device is located above the carton conveying mechanism 1 . The carton lid folding device is made up of cantilever frame 2, lid folding swing arm 5, gland mechanism 3, cylinder 6 and protective cover 7. The cantilever frame 2 is provided with a cantilever 4 and a vertical end, and the cantilever 4 and the vertical end form an included angle. The cantilever 4 is parallel to the carton conveying mechanism, and the end of the cantilever 4 is equipped with a protective cover 7, and the protective cover is formed by sandwiching two side plates opposite to each other. The cantilever 4 is also hinged with a folding cover swing arm 5 . A cylinder 6 is installed at the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com