Monitoring method for consumable consumption of ink-jet printing machine

A technology for inkjet printers and consumables, applied in printing and other directions, can solve the problems of inaccurate measurement, ink or solvent consumption cannot be measured in real time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The method for monitoring the consumables consumption of the inkjet printer proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

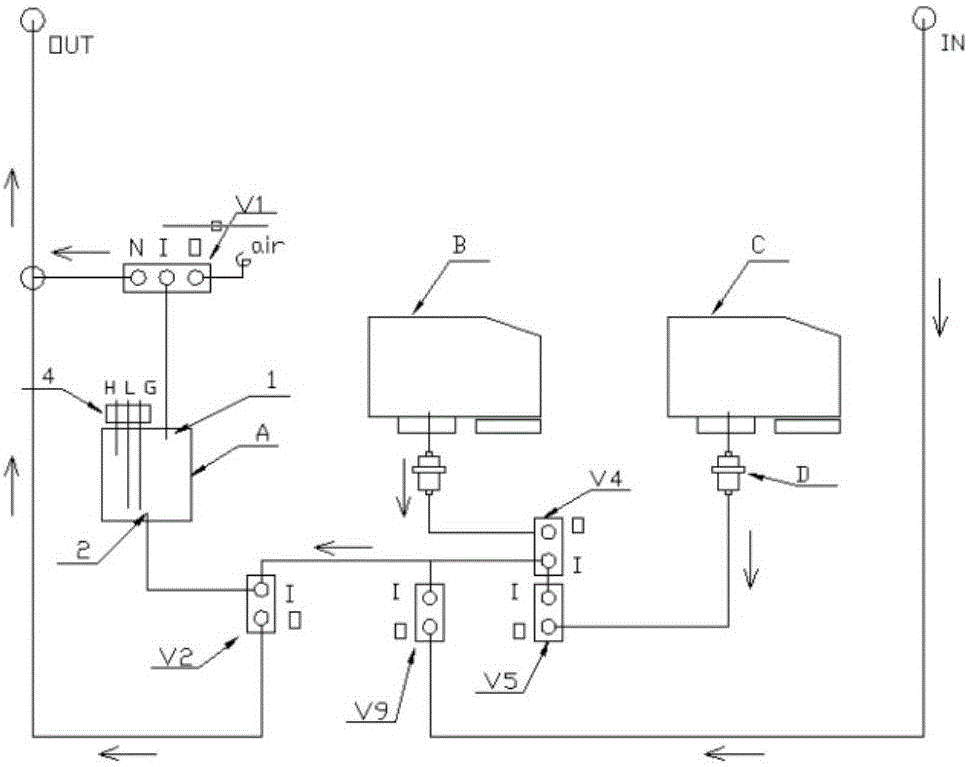

[0012] Please refer to figure 1 The monitoring device for the consumption of inkjet printer consumables includes: a consumable adding circuit, a metering device connected in series with the consumable adding circuit, and an inkjet printer ink circuit connected to the consumable adding circuit. The consumables added by the ink box B or the solvent box C in the consumables adding circuit all flow through the metering device for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com