Laser 3D printing platform for sand mold making

A 3D printing and sand molding technology, which is applied in the direction of casting molds, mold cores, and casting mold components, can solve the problems of prolonging the production cycle of parts, affecting equipment progress, and increasing equipment costs, so as to prevent loose sand, facilitate transportation, and stabilize the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

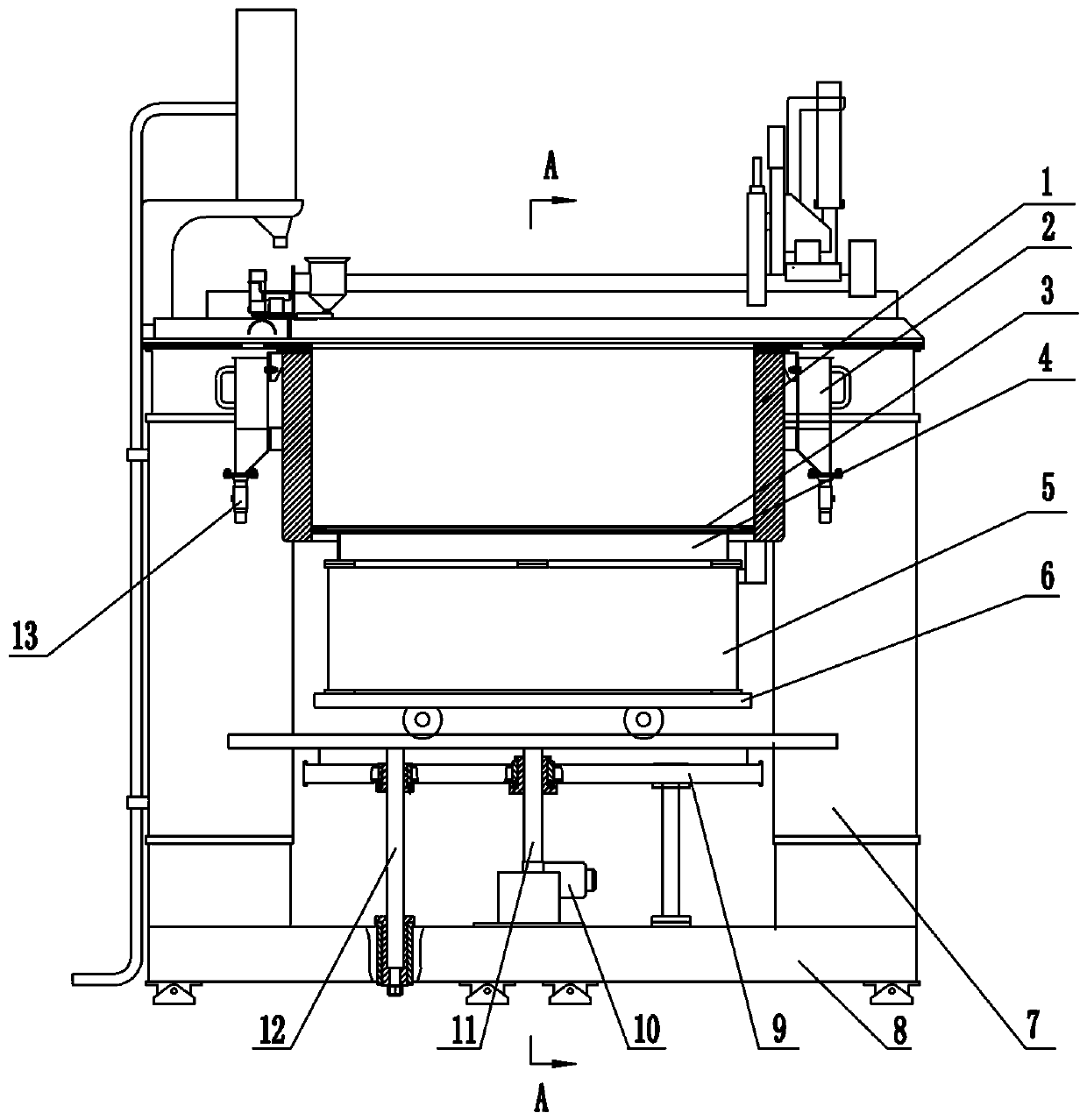

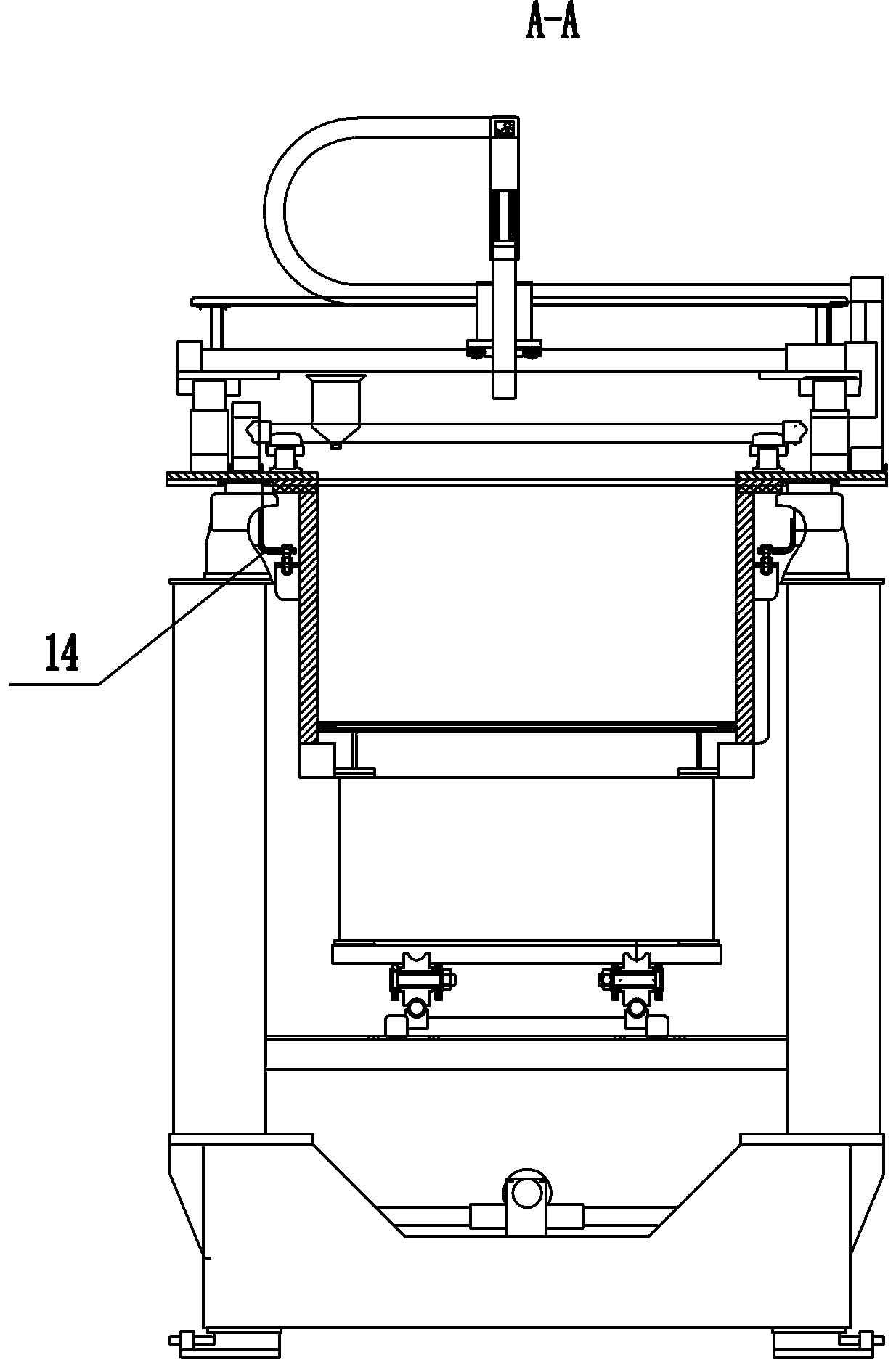

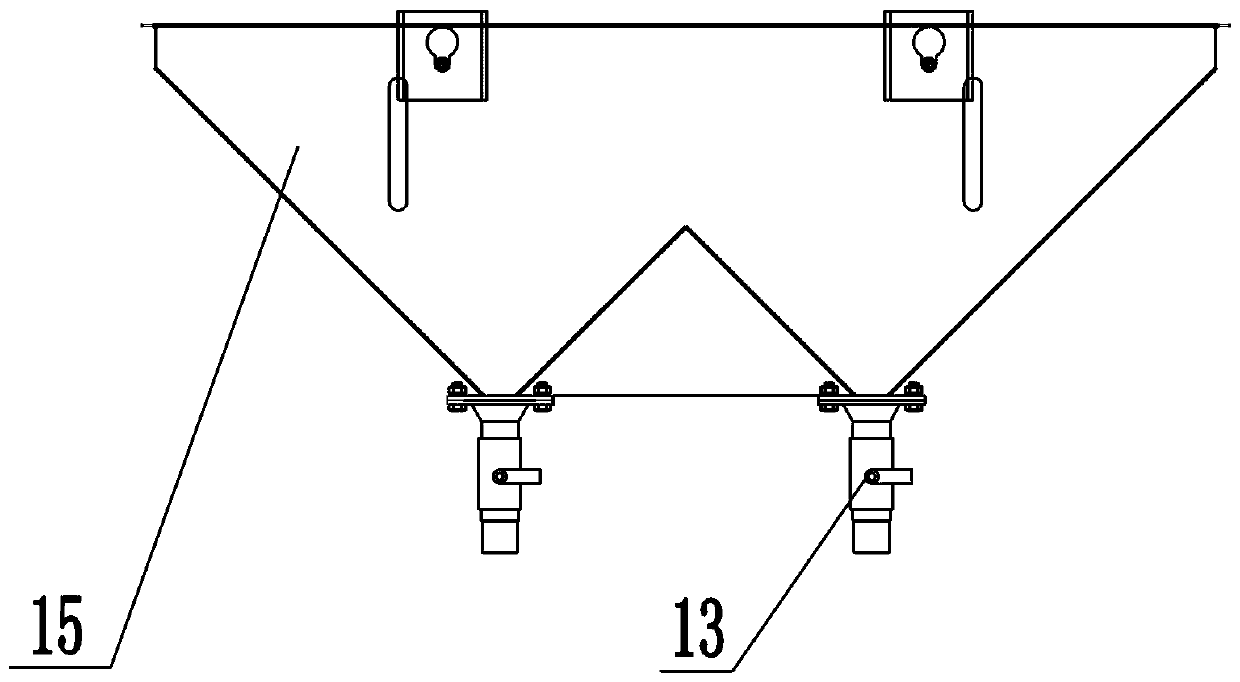

[0021] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] like figure 1 , 2 As shown in and 3, the laser 3D printing platform for sand mold making of the present invention is characterized in that it includes a base 8, a column 7 arranged around the base 8, a suspension frame 14 arranged on the top of the column 7, arranged on the base 8 The lifting system on the top, the shifting system set above the lifting system, the sand spreading platform 3 set on the shifting system, the solid molding sand box 1 surrounding the sand spreading platform 3, symmetrically arranged on the The collecting box 2 on both sides of the solid-forming flask 1, the top of the solid-forming flask 1 is fixedly connected with the suspension frame 13 by bolts,

[0023] Described lifting system comprises lifting platform 9, and the lifting device that is connected with this lifting platform 9, described lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com