Device for correcting distortions of longitudinal beams of automobiles

A technology of automotive longitudinal beams and pressing devices, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of low efficiency, poor precision of longitudinal beams, distortion and deformation of longitudinal beams, etc., and achieve flexible clamping and work efficiency High, high-precision correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

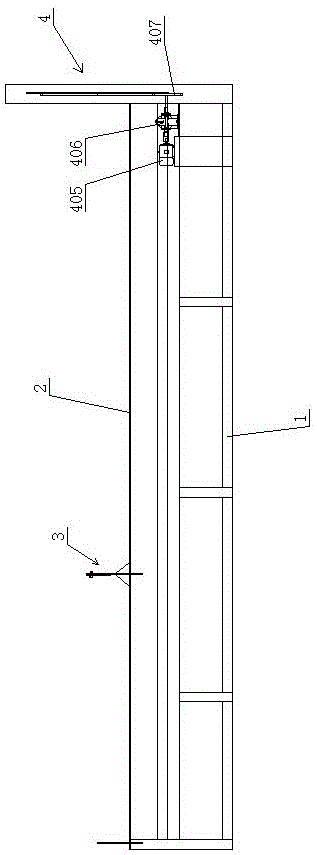

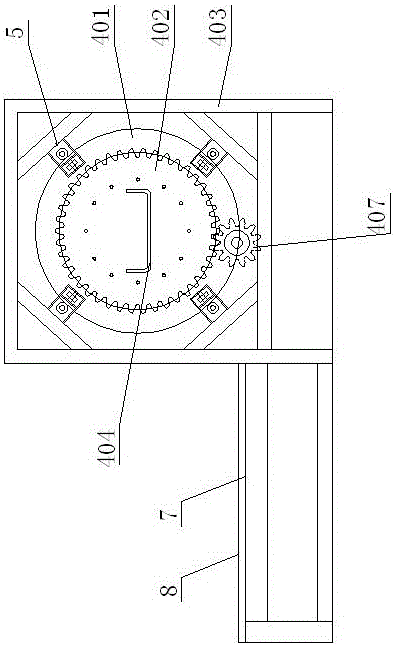

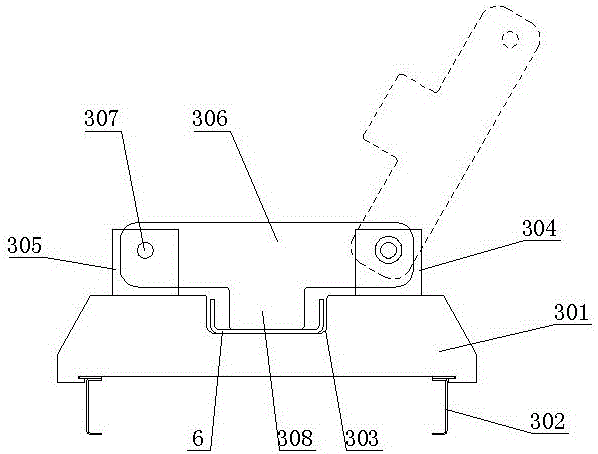

[0021] Such as Figure 1 ~ Figure 4 As shown, the present invention includes a base 1, on which a slide rail 2 is provided, on which a pressing device 3 slidingly connected thereto is provided, and one end of the base 1 is provided with a rotating device 4. The pressing device 3 comprises a support plate 301, the bottom of the support plate 301 is provided with a chute 302 slidably connected with the slide rail 2, the top of the support plate 301 is provided with a groove 303 adapted to the longitudinal beam 6, and the two sides of the groove 303 The supporting plate 301 is provided with a first connecting plate 304 and a second connecting plate 305, one end of the pressing plate 306 is hinged with the first connecting plate 304, the other end of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com