Rolling type joist steel low-temperature straightening device

A rolling and driving device technology, which is applied in the field of steel deep processing, can solve the problems of secondary damage and low correction accuracy of joist steel, and achieve the effects of avoiding secondary damage, high correction efficiency and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

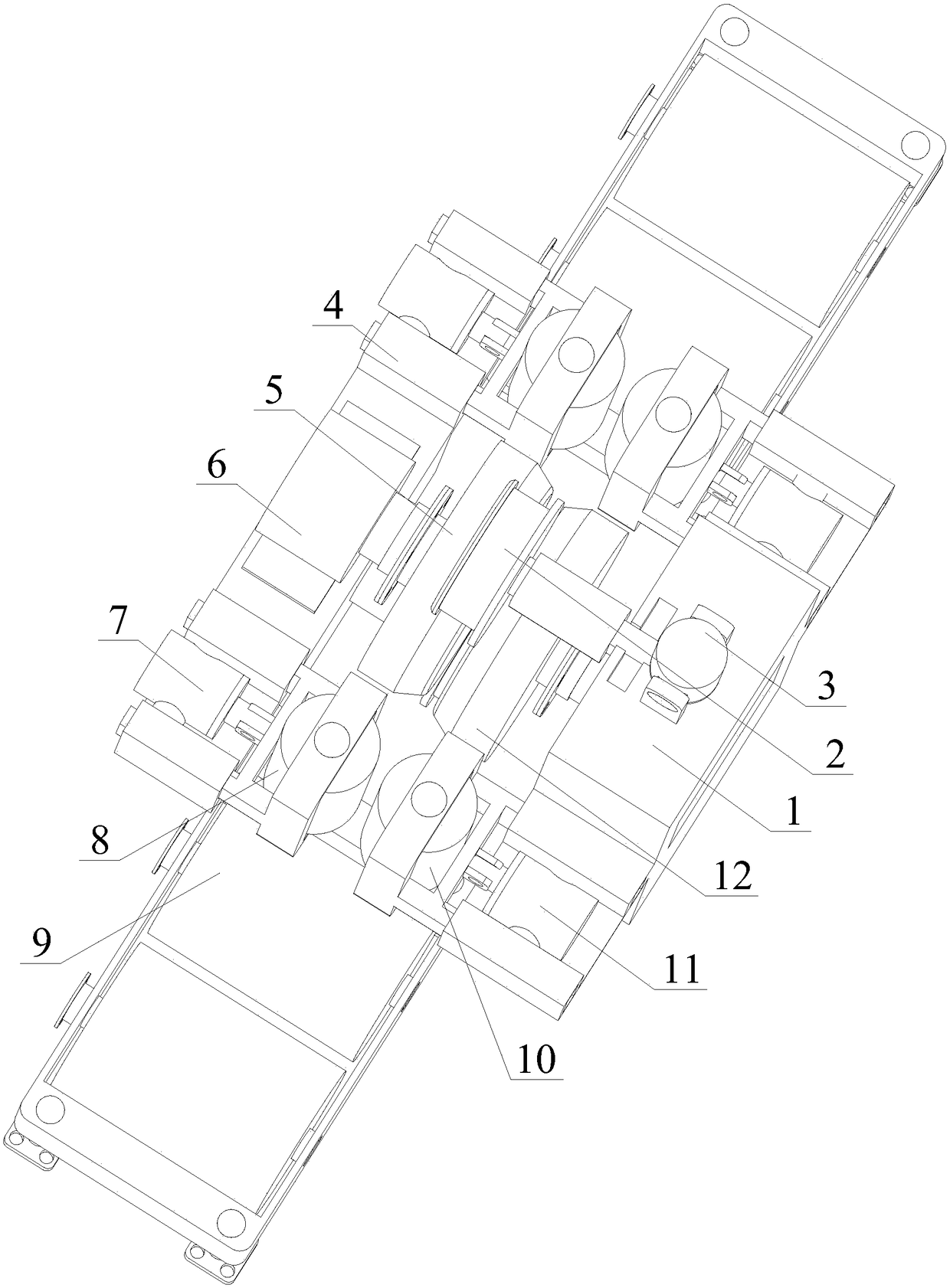

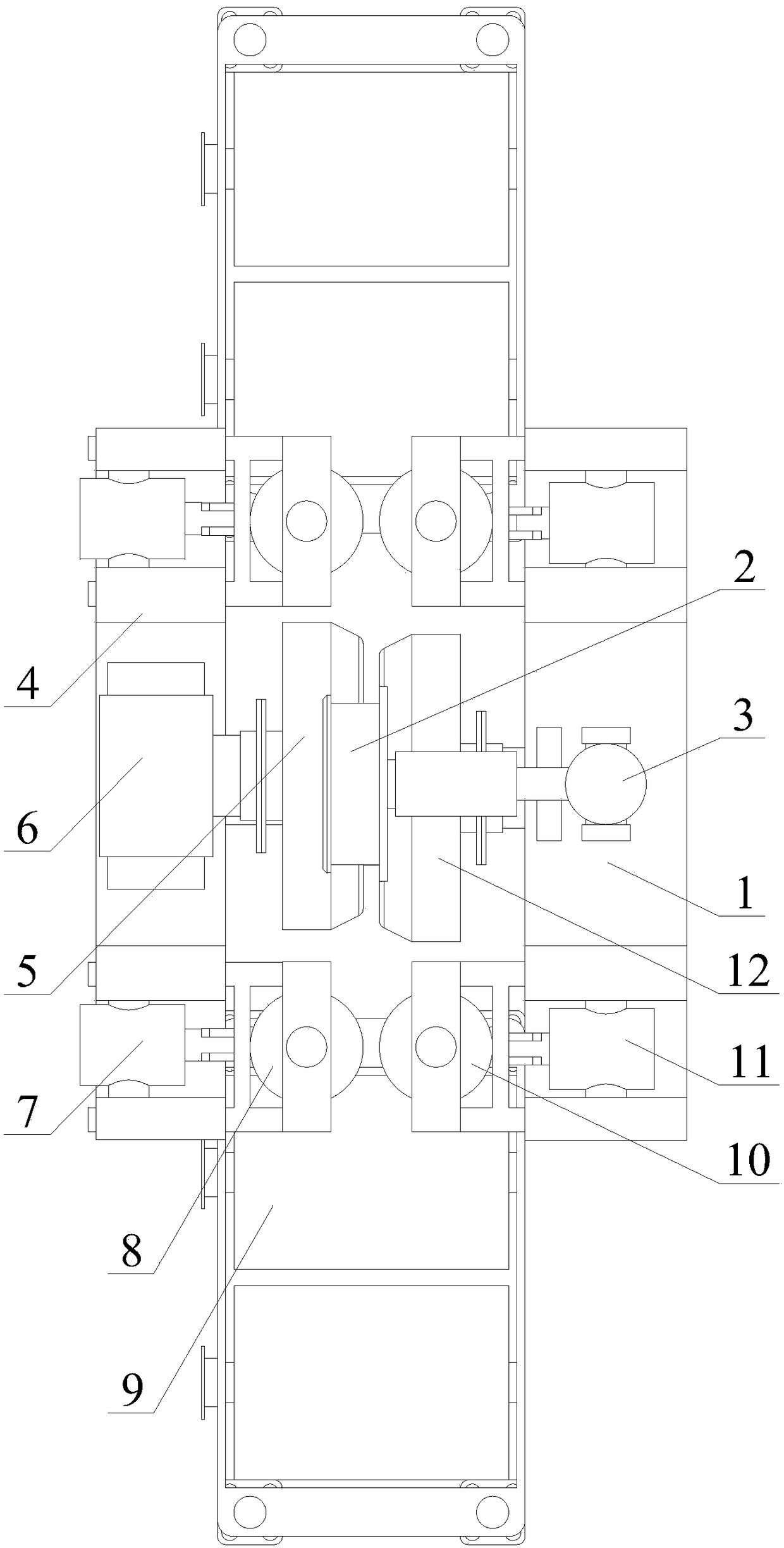

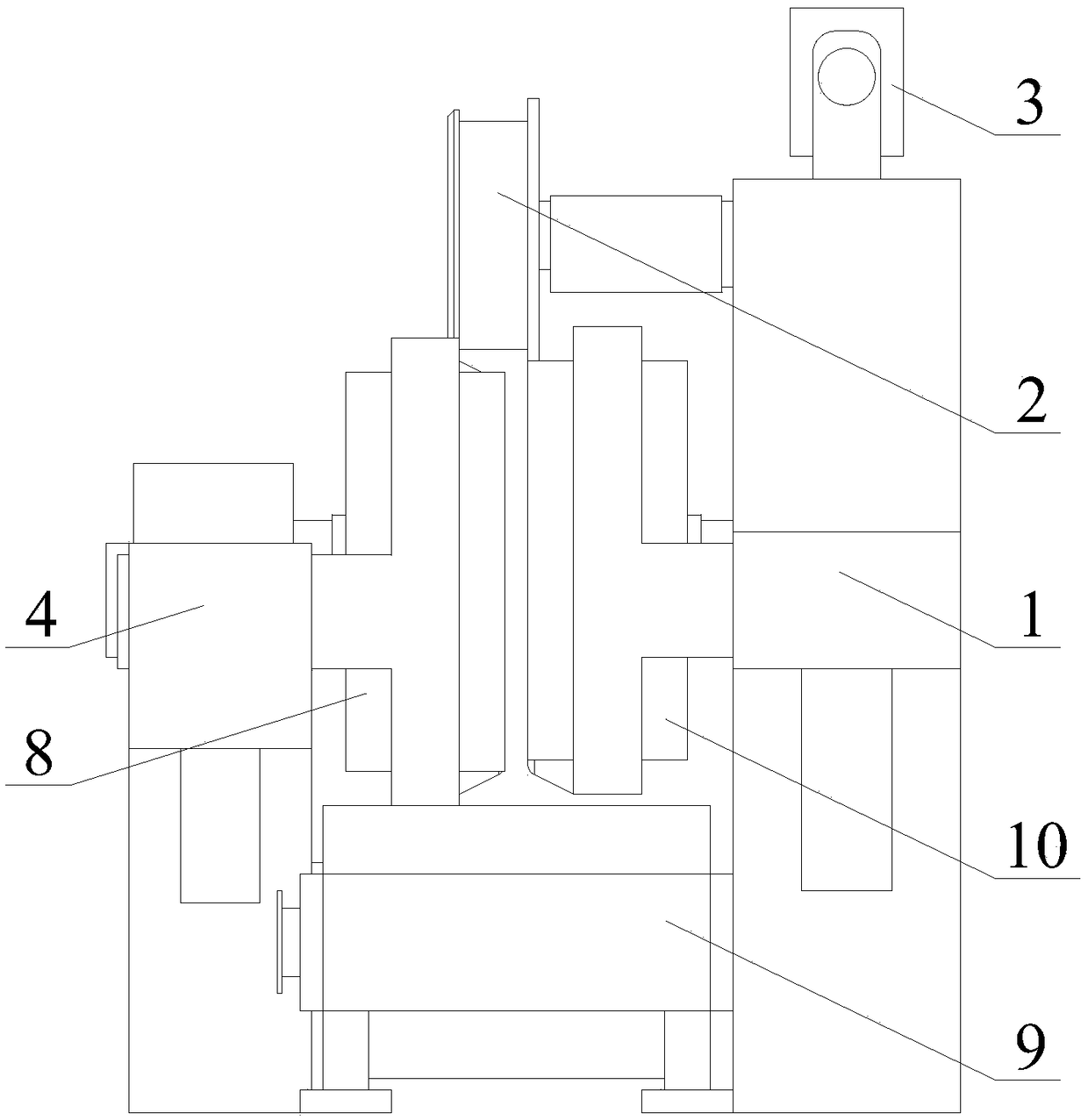

[0054] Such as Figure 1 to Figure 11 As shown, a first web straightening device 10, a first outer flange straightening device 2, a first inner flange straightening device 12, a first driving device 11, a third driving device 3, and a first web straightening device 1 are installed on the first worktable 1. Four driving devices 13; two first web straightening devices 10 and two first driving devices 11, located on both sides of the first outer flange straightening device 2 and the first inner flange straightening device 12 respectively. A second web correction device 8, a second outer flange correction device 14, a second inner flange correction device 5, a second drive device 7, and a fifth drive device 6 are installed on the second workbench 4; the second web The straightening device 8 and the second driving device 7 are two, respectively located on both sides of the second outer flange straightening device 14 and the second inner flange straightening device 5; two second web...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com