Full-automatic purging device for motor parts and cabinet

A purging equipment, fully automatic technology, applied in the direction of manipulators, program-controlled manipulators, cleaning methods using gas flow, etc., can solve the problems of inconvenient transportation, heavy screen cabinets, time-consuming and labor-intensive, and achieve energy saving and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

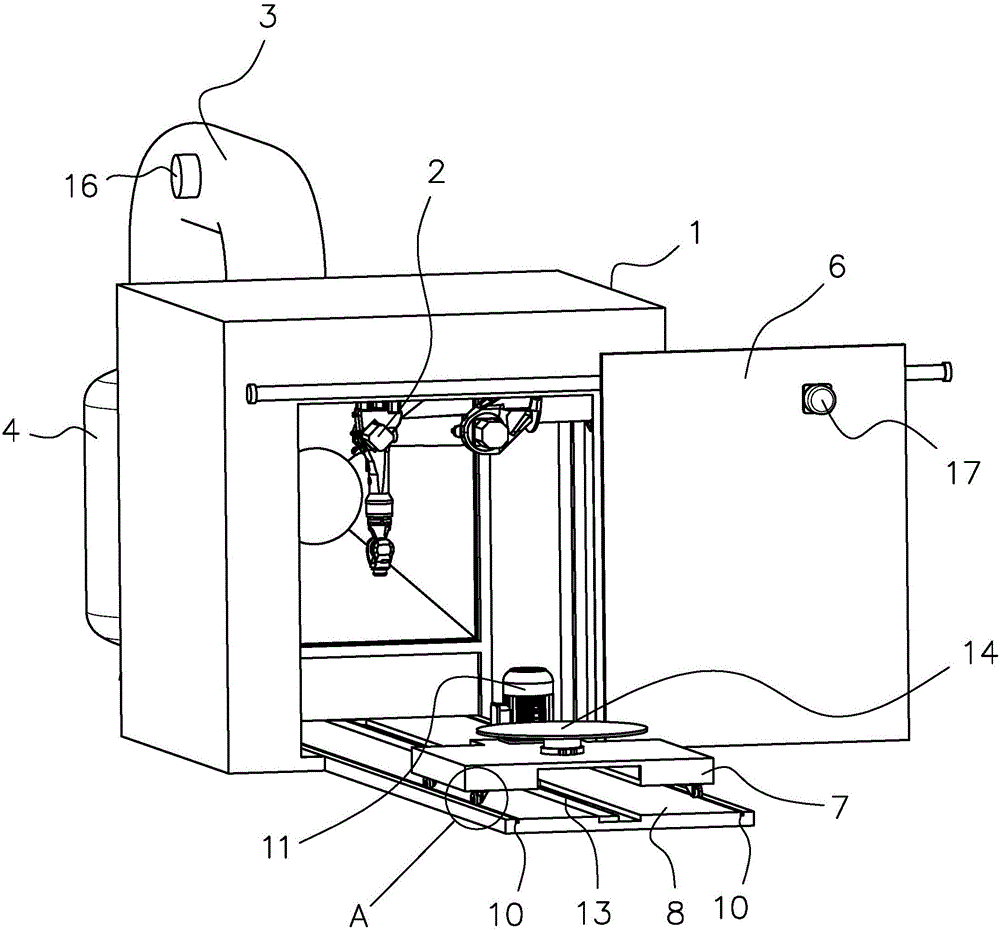

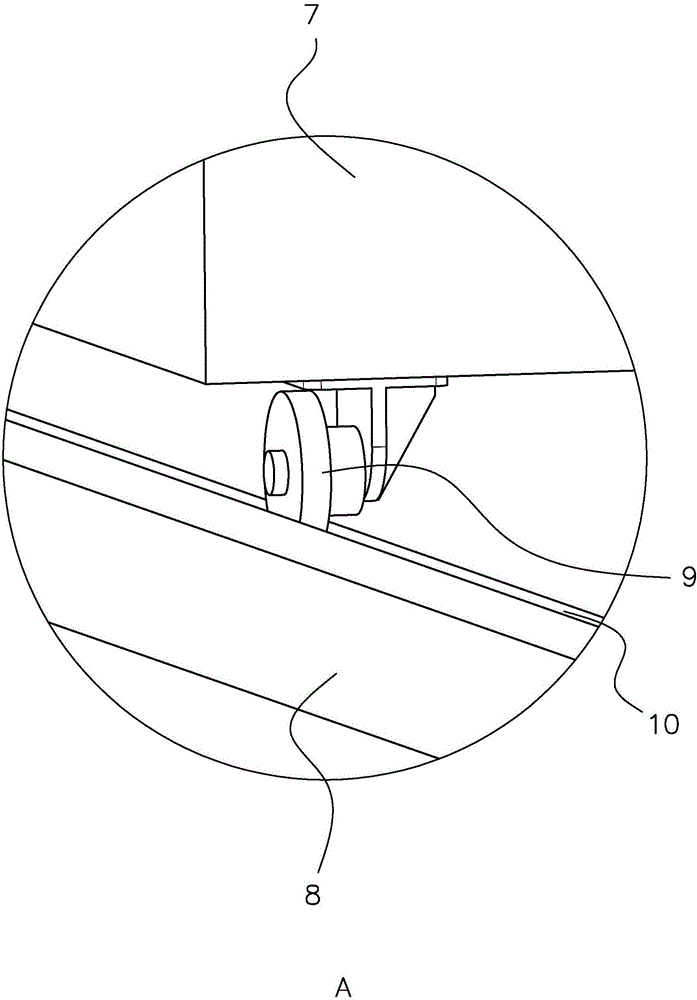

[0038] Embodiment 1, a fully automatic screen cabinet motor parts purging equipment, this equipment is widely used in the traction motor 11 and locomotive screen cabinets used in urban rail transit vehicles for overall and comprehensive cleaning operations, not only can clean the screen cabinets, but also It can clean motor components such as traction motor auxiliary motor, etc., with strong adaptability, such as figure 1 As shown, including dust removal chamber 1, dust removal chamber 1 is preferably welded and assembled by No. 50 channel steel. The plate is bent and assembled, fully enclosed, so that the structure of the dust removal room 1 is stronger. The dust removal room 1 is equipped with a robot arm 2 for purging the screen cabinet. The robot arm 2 is preferably YZ16-ARC-HW, and the robot arm is controlled by programming software. 2 probe track, in order to achieve the purpose of purging the entire screen cabinet, the software stores a variety of purging tracks for var...

Embodiment 2

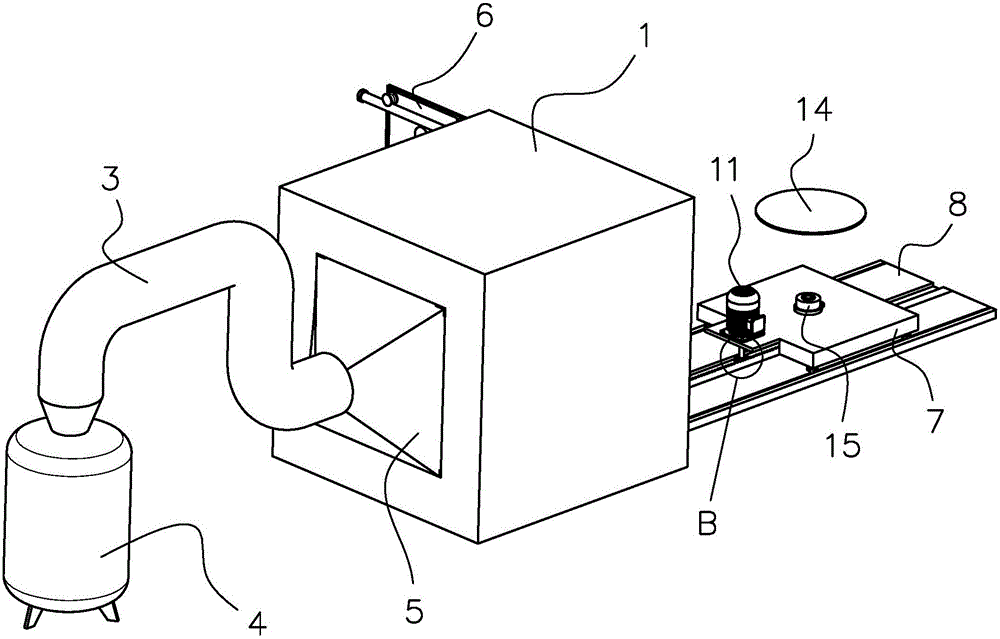

[0050] Embodiment 2, a kind of automatic screen cabinet motor parts purging equipment, such as Figure 7 As shown, it includes dust removal room 1, air guide port 5, air duct 3 elbow, exhaust pipe, fan, impact type dust collector 4, small intelligent robot arm 2, divider, turntable, touch industrial computer, integrated software system Electrical cabinets, electric automatic remote control roller shutter doors, touch screens, controller pipes, explosion-proof lights and police lights.

[0051] The length × width × height of dust removal chamber 1 is 45000 × 5000 × 4500 respectively. It is welded and assembled by No. 63 channel steel, bent by stainless steel plate, and the inner and outer layers are stainless steel; the air guide port 5 is connected to the purge chamber, through The stainless steel air duct 3 is connected to the dust removal room 1; the front door is equipped with a transparent rubber door curtain with a width × height of 3000 × 3000, and a mechanical arm 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com