Self-sealing sliding contact conductive device

A conductive device, self-enclosed technology, applied in the direction of circuits, current collectors, electrical components, etc., can solve problems such as no solution, high cost, difficult construction, etc., to prevent personal electric shock and line leakage accidents, low cost, easy to manufacture and install Easy and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

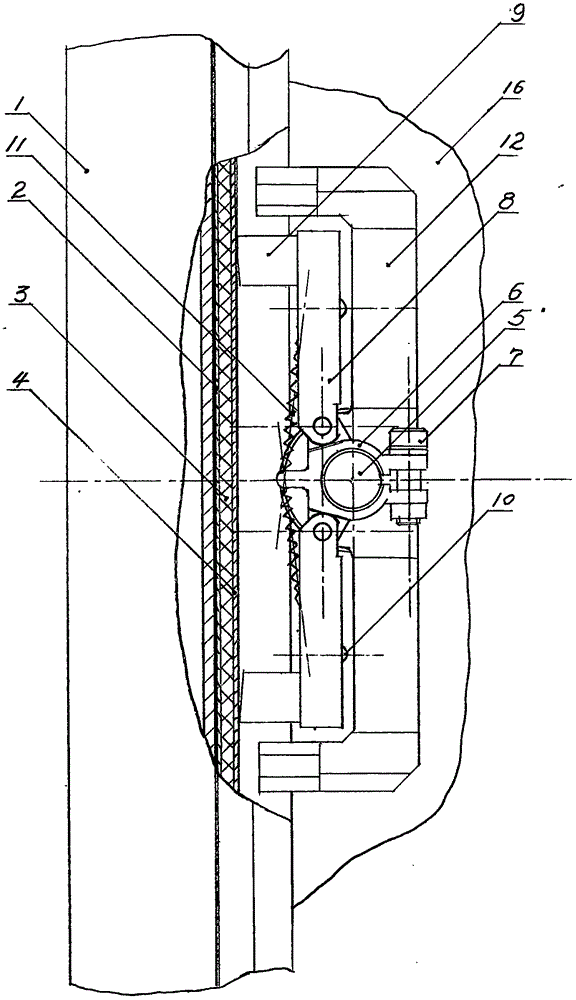

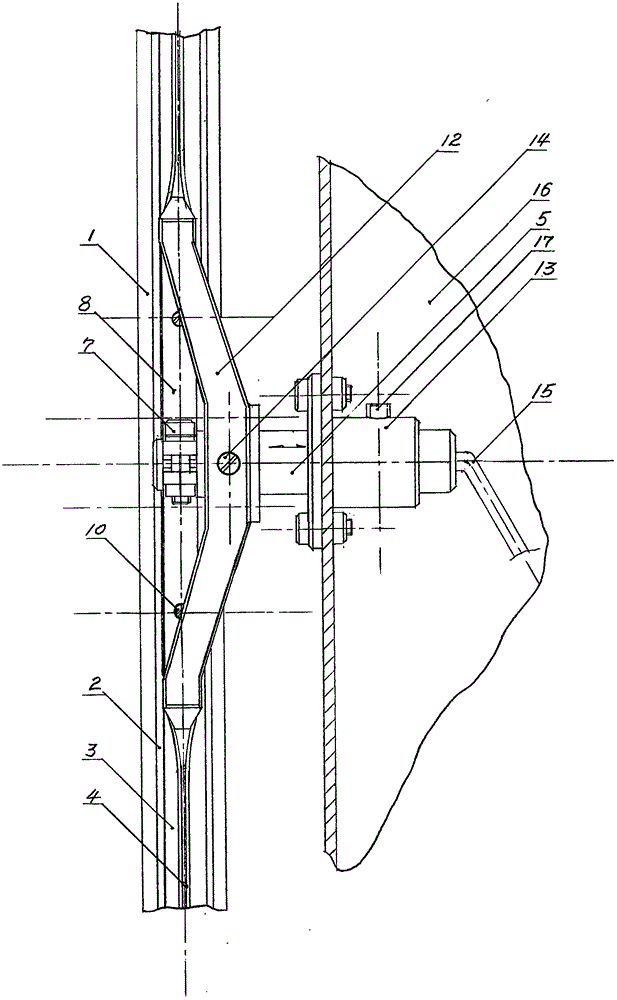

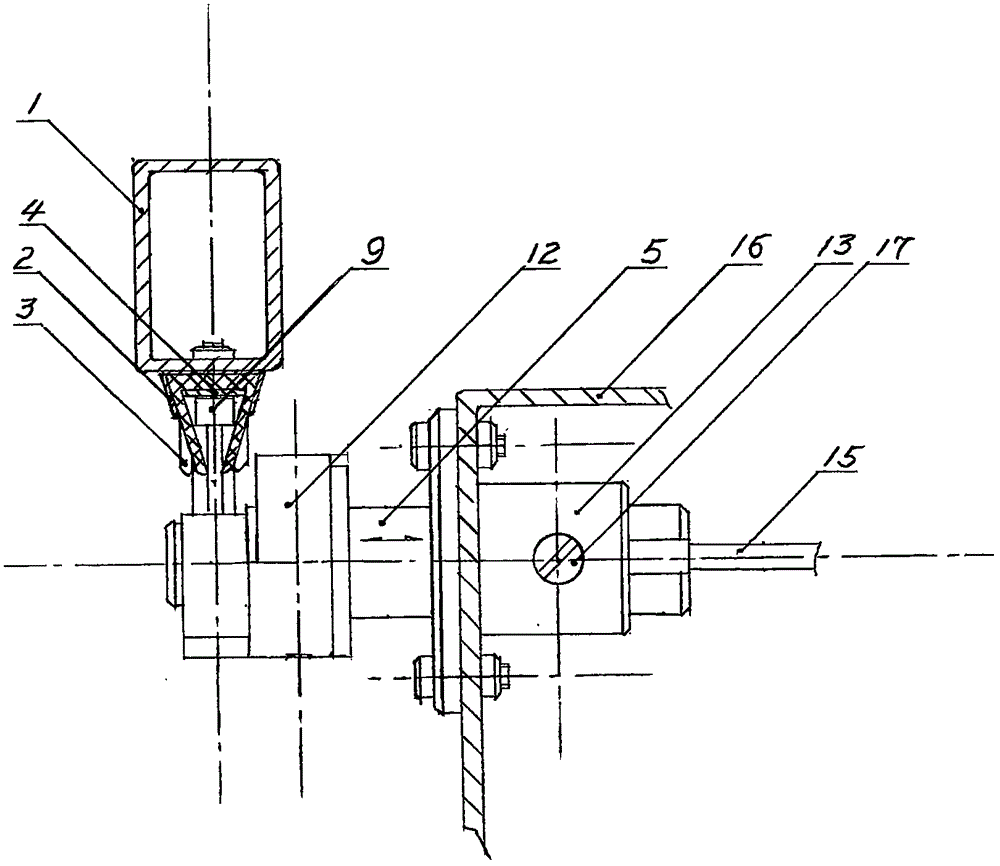

[0011] In the figure, the conductive red copper strip (4) is inlaid in the inner bottom of the triangular rubber insulating base strip (3) with an opening at the front corner, and is held by the conductive strip shell (2) to form a conductive strip assembly of the entire length, which is installed on the conductive strip shell (2). on the bracket tube (1) and connect it to the power supply. Fix the copper sliding contact center frame (6) on the outer end shaft head of the sliding contact insulation center shaft (5), and fasten it together with the outer end of the wire (15) with the fastening screw (7) Together. The two wings of the copper sliding contact center frame (6) are respectively fitted with a conductive voltage arm (8), and the ends of the two conductive voltage arms (8) are each fitted with a graphite brush (9). And fasten firmly by electric brush fastening screw bar (10). Two conduction voltage arms are tensioned by a compression arm extension spring (11) respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com