TR and Duffing system combined ultrasonic guided wave small defect positioning and detecting method

An ultrasonic guided wave, positioning detection technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of small defect signals being interfered by the outside world and the inability to determine the location information of small defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

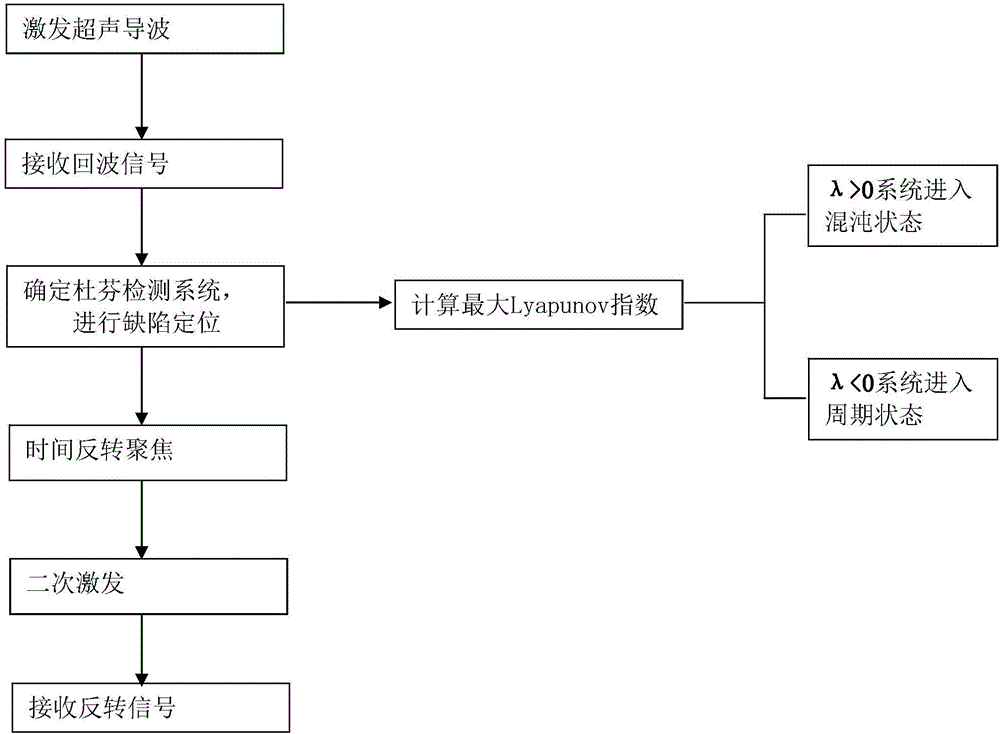

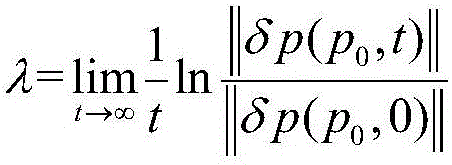

[0034] Such as figure 1 As shown, a kind of TR and the Duffing system combination ultrasonic guided wave small defect localization detection method that the present invention provides, this method comprises the following steps:

[0035] (1) Excite the ultrasonic guided wave signal S=f sin(wt) modulated by the Hanning window on one end surface A of the pipeline, and excite the guided wave of the pipeline mode, which is commonly used in the L(0,2) mode, T(0,1) The mode is used as the signal to be detected, so that the ultrasonic guided wave traverses all positions of the pipeline;

[0036] (2) The receiving end B near the excitation end (according to the different detection sites, the distance between the AB end is also different, generally about 10 meters) receives the echo signal of the ultrasonic guided wave and records the time cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com