Maintainable tunnel lining water pressure and displacement monitoring system

A displacement monitoring and tunnel technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of no early warning, inability to meet long-term monitoring, and low service life of water pressure gauges, to ensure reliability and service life, reduce inspection workload, Guaranteed effect of long-term reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

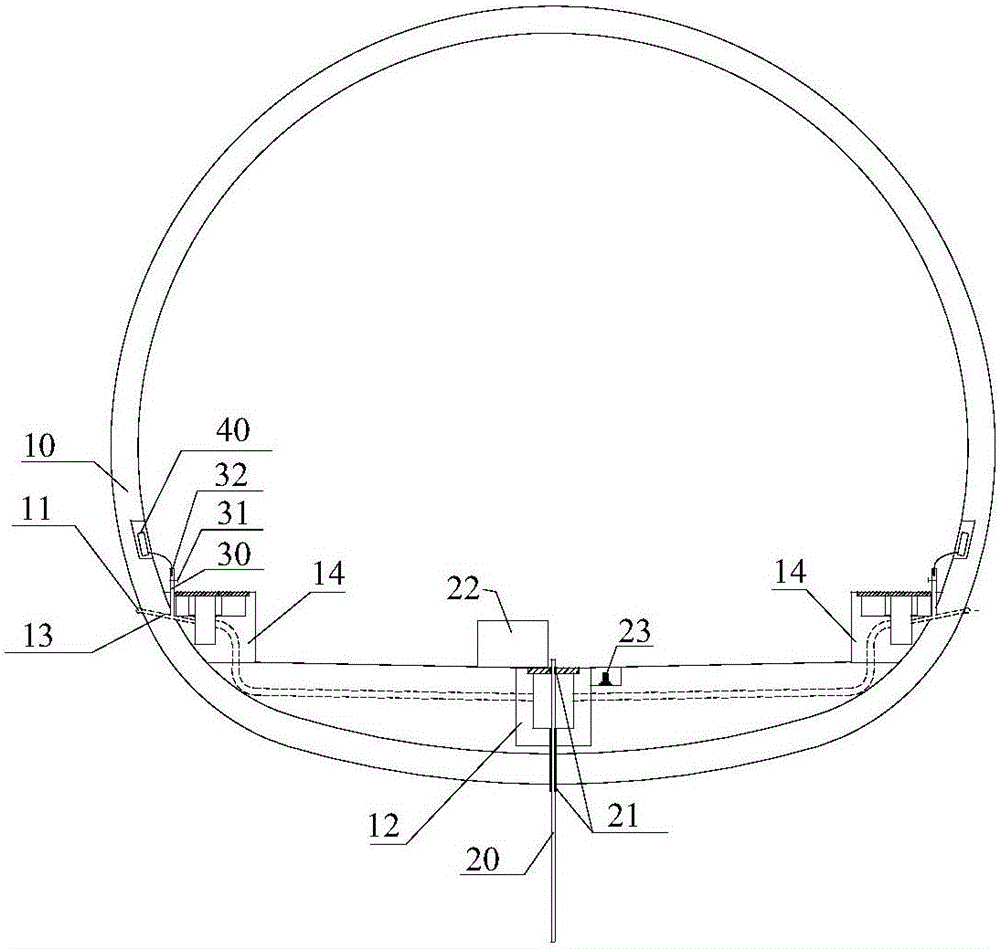

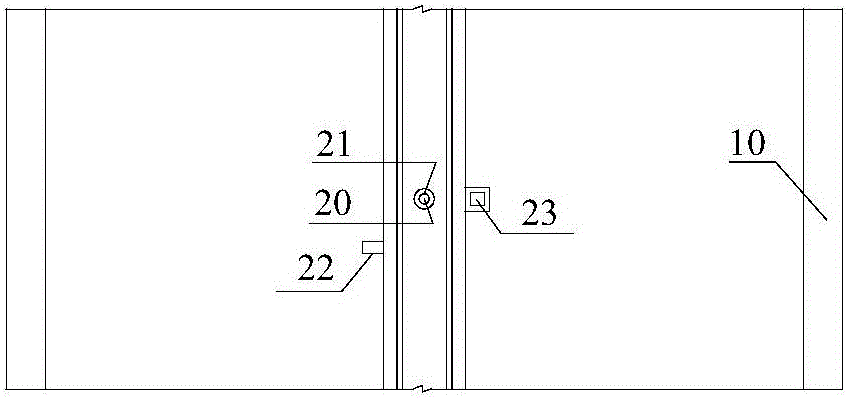

[0012] refer to figure 1 , a maintainable tunnel lining water pressure and displacement monitoring system of the present invention, monitoring sections are arranged at intervals along the tunnel extension direction, and hydraulic pressure monitoring devices, displacement monitoring devices, wireless data adopters 40, and repeaters are arranged on each monitoring section , the water pressure monitoring device is set above the drainage ditches 14 on both sides outside the tunnel lining 10, the displacement monitoring device is set at the invert filling layer above the invert section of the tunnel lining 10 and the center ditch 12, the tunnel lining detected by the water pressure monitoring device The water pressure value at the back of 10 and the up-and-down displacement value of the tunnel lining 10 inverted arch section detected by the displacement moni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com