Gas tank piston and T baffle offset and torsion measuring methods and devices

A measurement method and gas cabinet technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of rubber film tearing, safety hazards, economic losses, etc., to reduce the number of measurements, improve safety, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

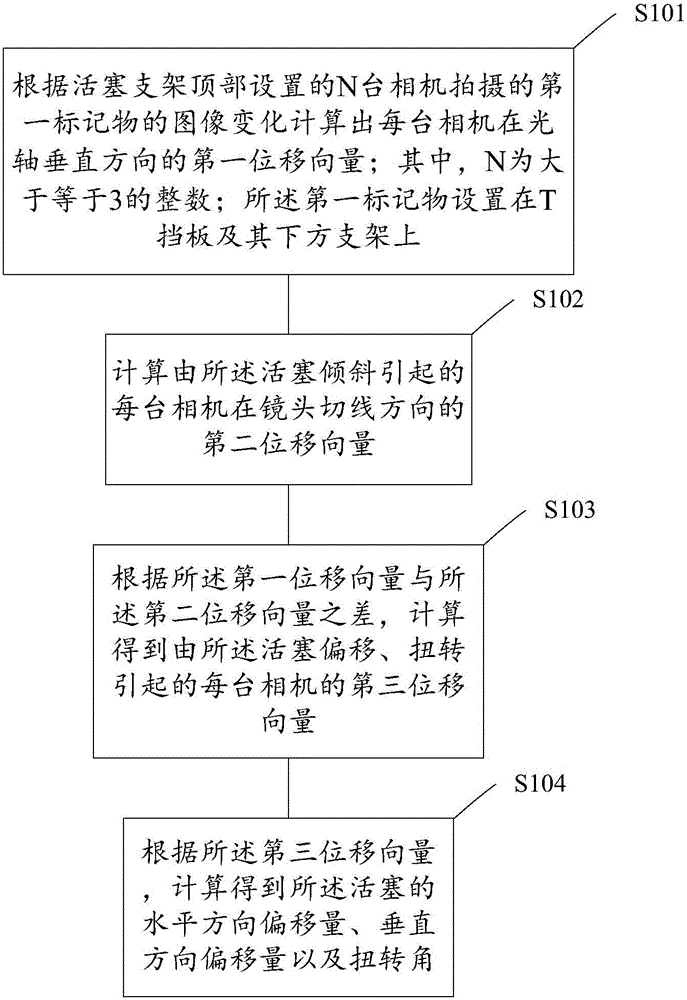

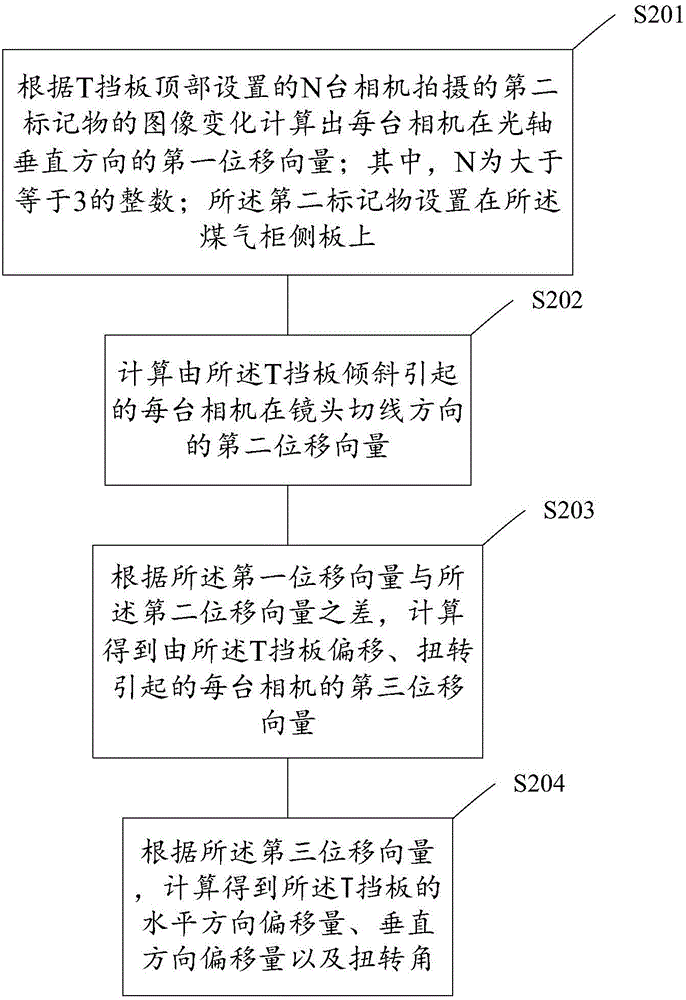

[0054] The embodiment of the present invention provides a method and device for measuring the offset and torsion of the gas cabinet piston and T baffle in order to solve the problems in the prior art that the detection of the running state of the gas cabinet piston and T baffle is inaccurate or requires manual measurement. During the operation of the gas cabinet, when the piston is at the initial position, record the image of the marker captured by the camera on the piston. If the piston does not twist and shift, the position of the camera on the horizontal plane will not change, due to the marking The object is the same in the vertical direction, so the image taken by the camera is no different from the image at the initial position. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com