Silencing cavity bottom hole depth gauge

A sound-absorbing cavity and depth gauge technology, which is applied in the field of cavity bottom holes, can solve the problems of inconvenient detection of the depth of threaded holes and the reduction of threaded holes, etc., and achieve the effect of realizing the scope of use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

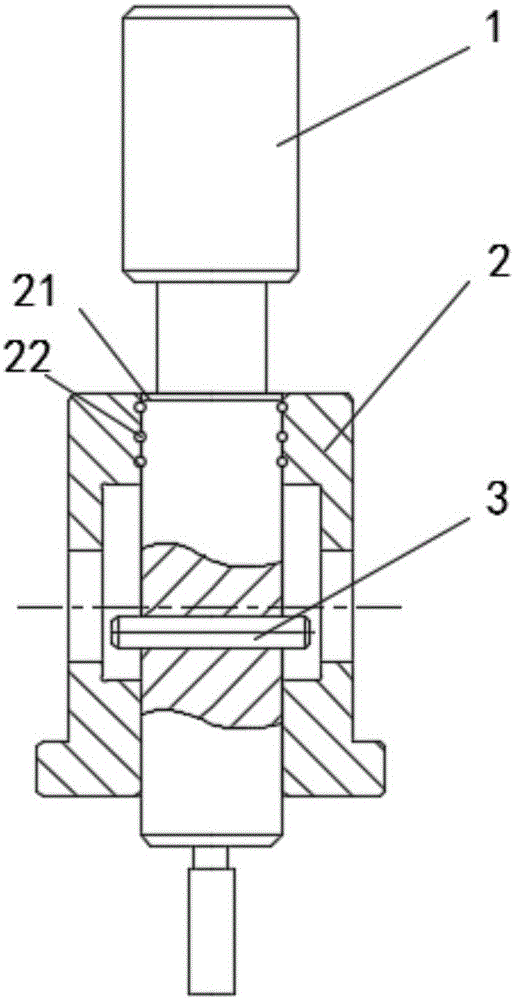

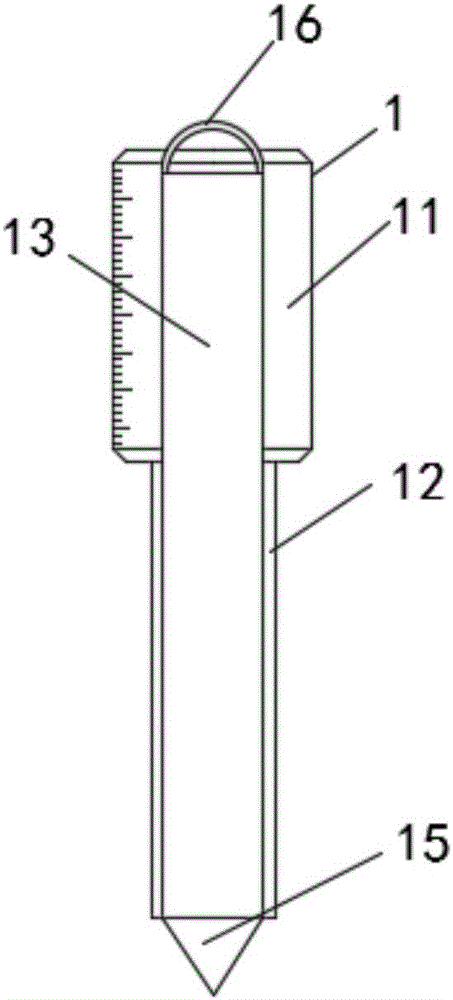

[0016] see Figure 1-2 , the present invention provides a technical solution: a depth gauge for the bottom hole of the muffler chamber, including a measuring rod 1 and a support sleeve 2, the inner cavity of the support sleeve 2 is provided with a through hole 21, and the support sleeve 2 is provided with a Cylindrical pin 3, the measuring rod 1 includes a moving rod 13, a transparent rod handle 11 and a rod sleeve 12, the bottom end of the moving rod 13 is connected with a plug 15, and the plug 15 is exposed on the outside of the rod sleeve 12, The plug 15 is an inverted conical shape, the upper end of the transparent rod handle 11 is connected to the lower end of the rod cover 12, the moving rod 13 is inserted into the transparent rod handle 11 and the rod cover 12, the moving rod 13 The upper end shaft is connected with a pull ring 16, and one end of the transparent shank 11 is inserted into the through hole 21 of the support sleeve 2, and the plug 15 is inserted into the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com