Method for manufacturing longitudinal water beam of walking beam heating furnace and longitudinal water beam

A manufacturing method and technology of vertical water beams, applied in the field of vertical water beams, can solve the problems of cumbersome trial calculations, error-prone, laborious, etc., and achieve the effects of improving calculation accuracy, simplifying the manufacturing process, and reducing the number of trial calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For ease of understanding, the manufacturing method of the longitudinal water beam of the walking beam heating furnace and the longitudinal water beam provided by the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

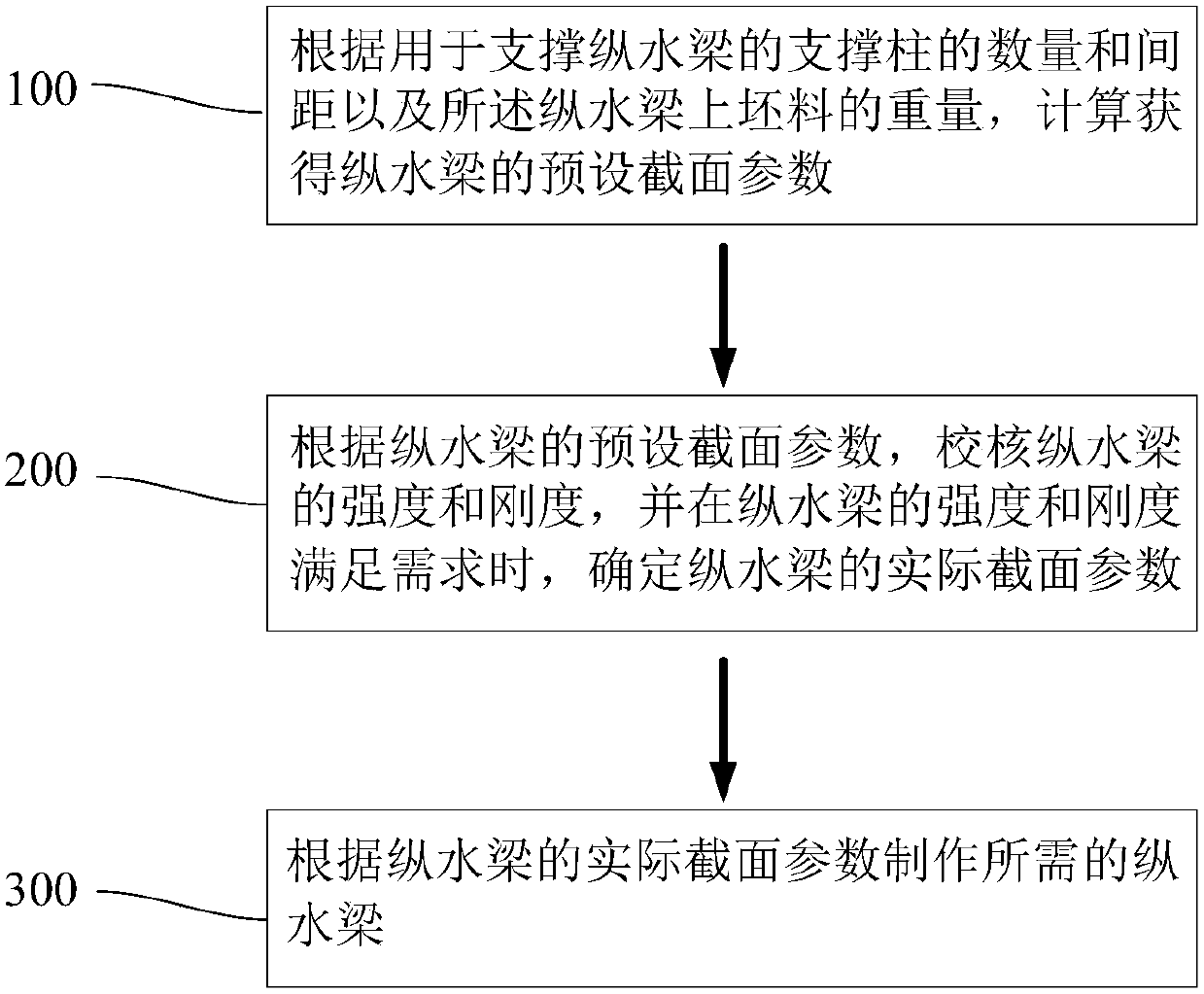

[0026] see figure 1 , the manufacturing method of the longitudinal water beam of the walking beam heating furnace provided in the embodiment of the present invention includes:

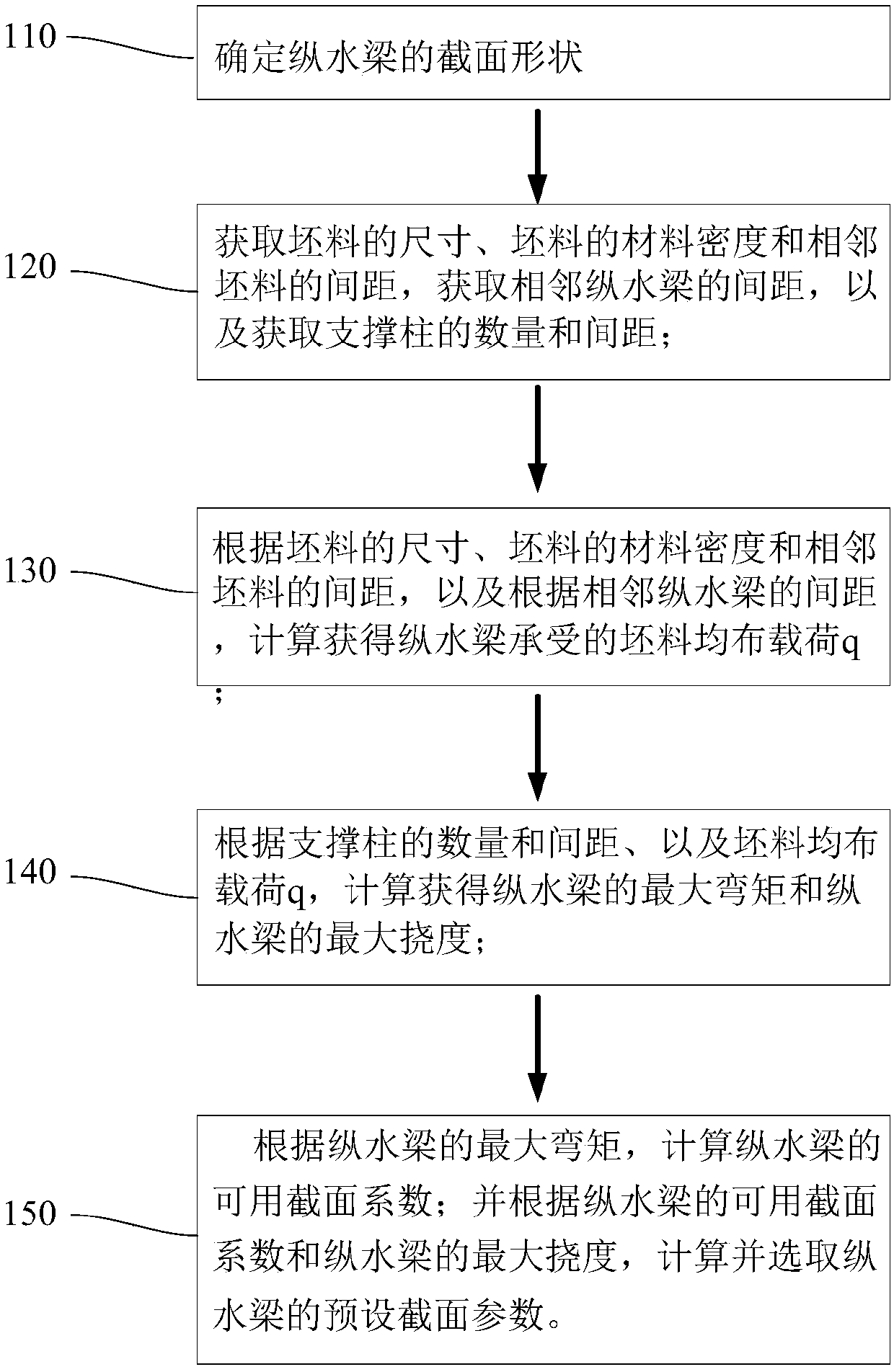

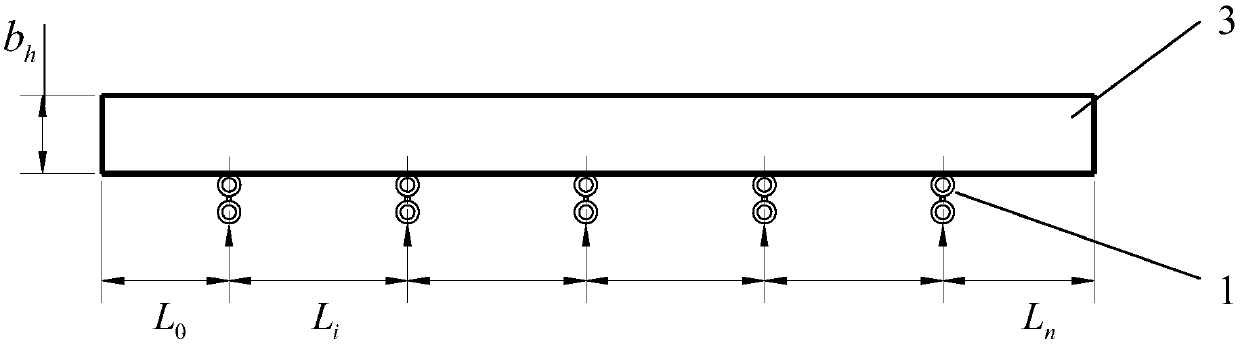

[0027] Step 100 , according to the number and spacing of support columns 2 used to support the longitudinal water beam 1 and the weight of the blank 3 on the longitudinal water beam 1 , calculate and obtain the preset section parameters of the longitudinal water beam 1 . In this step, first set the number and spacing of support columns 2 according to the length of the heating furnace and other actual needs, then select the cross-sectional shape type of the longitudinal water beam 1, and then according to the number a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com