Air cooling hydraulic station with secondary heat dissipating pipeline

A technology for secondary heat dissipation and hydraulic station, applied in the field of air-cooled hydraulic station, can solve the problem that the effect of the heat dissipation method of a separate fan needs to be improved, and achieve the effect of good secondary heat dissipation, good heat dissipation effect, and reduced traveling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

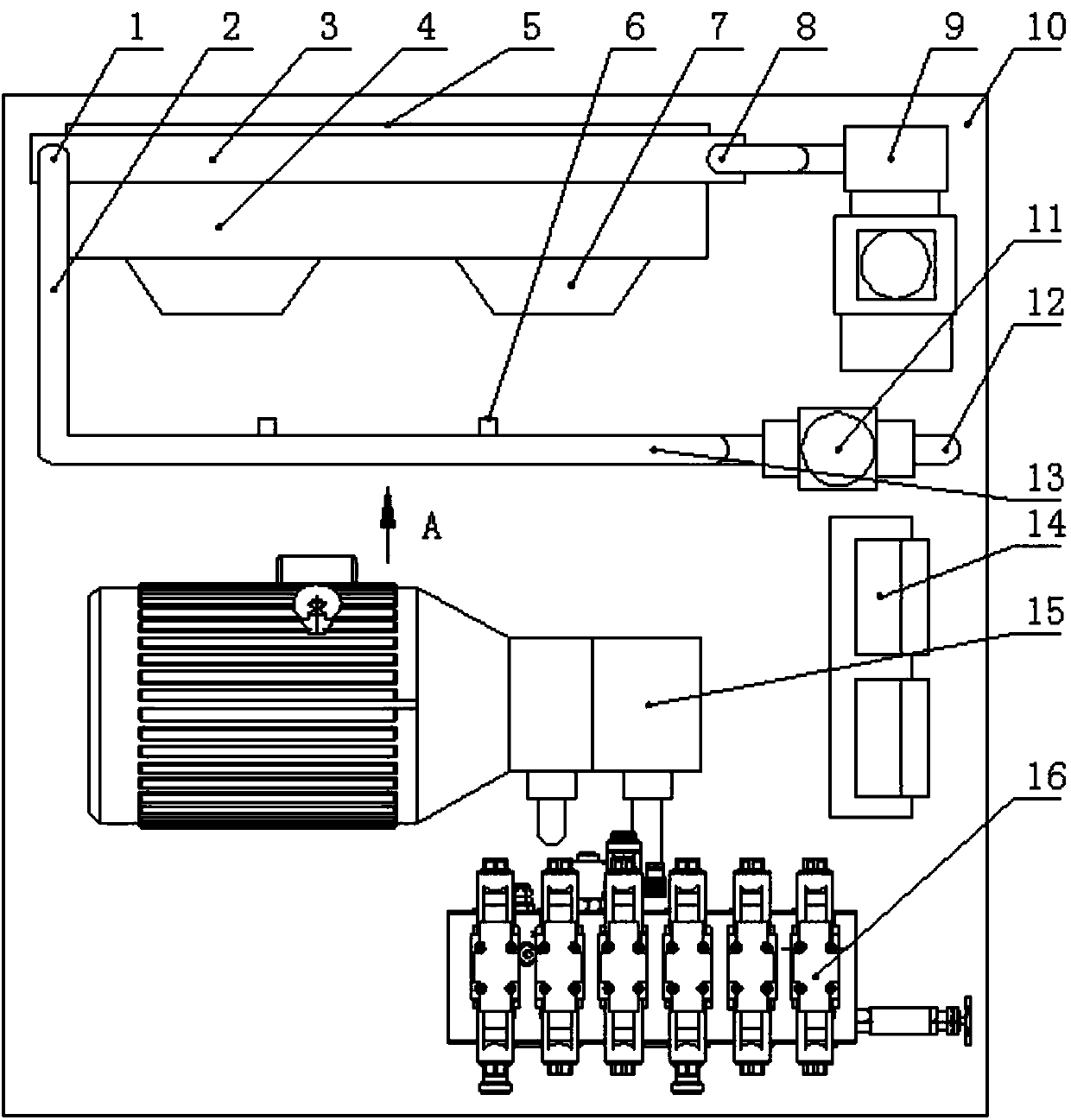

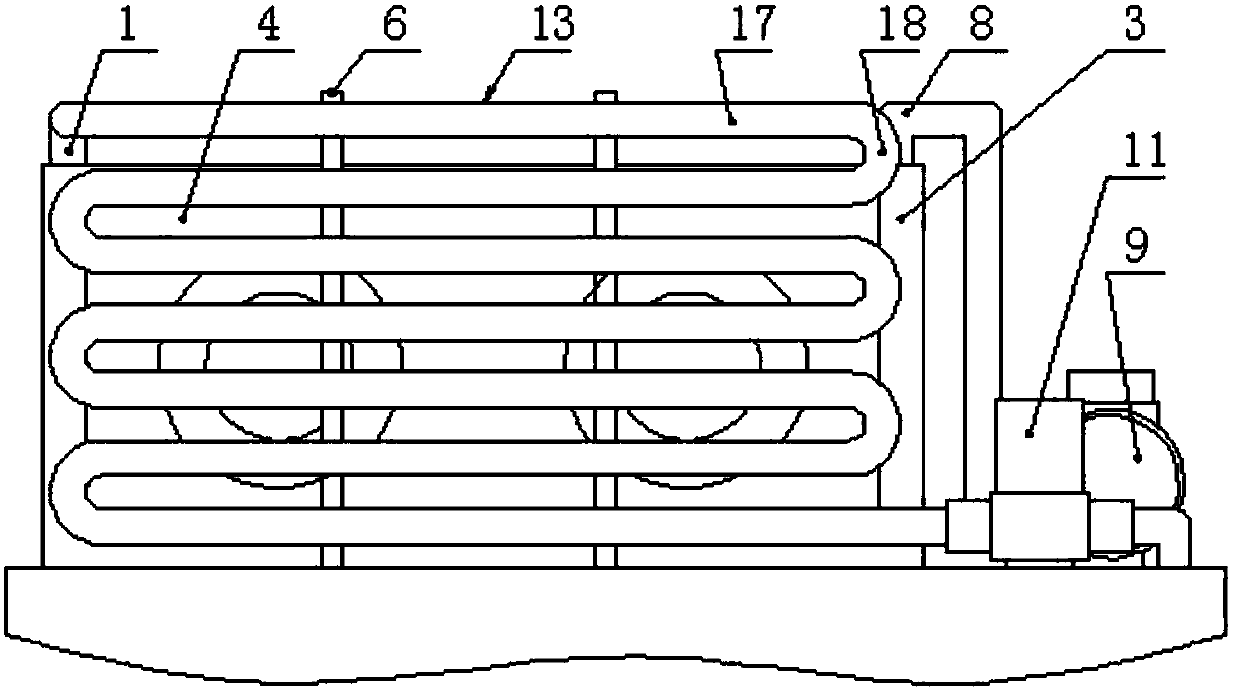

[0015] An air-cooled hydraulic station with a secondary cooling line, such as figure 1 , 2 As shown, this book includes a fuel tank 10, an oil supply power source 15, a switch valve group 16, a radiator 3 and a fan outer shell 4, and the innovation of the present invention is that the switch valve group is installed on the front end of the upper end face of the fuel tank, and the switch valve group The oil supply power source is installed on the upper end surface of the fuel tank at the rear, and the fan housing is installed on the rear end of the upper end surface of the fuel tank. The fan housing is installed with a radiator facing the outside of the fuel tank, and cooling fins 5 are installed on the radiator. The fan casing is facing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com