Sulfocompound selective catalytic oxidation reaction system in aqueous phase

A reaction system, catalytic oxidation technology, used in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

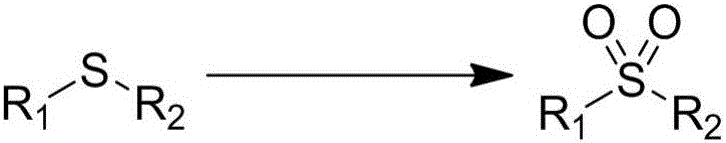

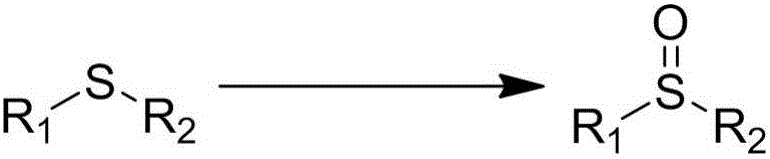

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A selective catalytic oxidation reaction system for sulfur-containing compounds in the water phase of the present invention is synthesized by the following method:

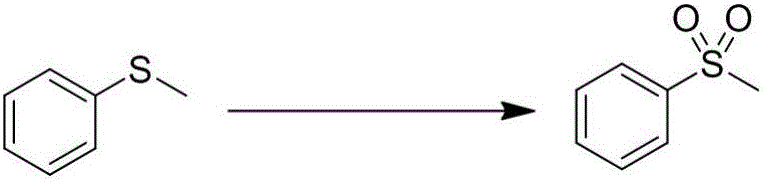

[0025] Stir 5 μmol of catalyst, 2 mmol of sulfide anisole, and 6 mmol of 30% hydrogen peroxide in 4 mL of water at room temperature for 1.5 hours, the conversion rate reaches 99%, and the selectivity of the product sulfone reaches 96%. After the reaction is finished, it is extracted with ethyl acetate, and after the organic phase is separated, the catalyst is dispersed in the water phase and can be directly used for the next catalytic reaction. Catalytic activity is maintained, and both conversion and selectivity are maintained.

[0026]

[0027] Stir 1.2 μmol of catalyst, 2 mmol of sulfide anisole, and 2 mmol of 30% hydrogen peroxide in 3 mL of water at room temperature for 6 hours, the conversion rate reaches 93%, and the selectivity of the product sulfone reaches 91%. After the reaction is finished, ...

Embodiment 2

[0030] A selective catalytic oxidation reaction system for sulfur-containing compounds in the water phase of the present invention is synthesized by the following method:

[0031] Stir 5 μmol of catalyst, 2 mmol of diethyl sulfide, and 6 mmol of 30% hydrogen peroxide in 4 mL of water at room temperature for 1.5 hours, the conversion rate reaches 98%, and the selectivity of the product sulfone reaches 99%. After the reaction is finished, it is extracted with ethyl acetate, and after the organic phase is separated, the catalyst is dispersed in the water phase and can be directly used for the next catalytic reaction. Catalytic activity is maintained, and both conversion and selectivity are maintained.

[0032]

[0033] Stir 1.2 μmol of catalyst, 2 mmol of sulfide anisole, and 2 mmol of 30% hydrogen peroxide in 3 mL of water at room temperature for 6 hours, the conversion rate reaches 94%, and the selectivity of the product sulfone reaches 90%. After the reaction is finished, ...

Embodiment 3

[0036] A selective catalytic oxidation reaction system for sulfur-containing compounds in the water phase of the present invention is synthesized by the following method:

[0037] Stir 5 μmol of catalyst, 2 mmol of ethyl propyl sulfide, and 6 mmol of 30% hydrogen peroxide in 4 mL of water at room temperature for 2 hours, the conversion rate reaches 99%, and the selectivity of the product sulfone reaches 99%. After the reaction is finished, it is extracted with ethyl acetate, and after the organic phase is separated, the catalyst is dispersed in the water phase and can be directly used for the next catalytic reaction. Catalytic activity is maintained, and both conversion and selectivity are maintained.

[0038]

[0039] Stir 1.2 μmol of catalyst, 2 mmol of ethyl propyl sulfide, and 2 mmol of 30% hydrogen peroxide in 3 mL of water at room temperature for 6 hours, the conversion rate reaches 91%, and the selectivity of the product sulfone reaches 83%. After the reaction is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com