A special flatbed trailer for harvesting machinery

A flatbed trailer and mechanical technology, applied in the direction of motor vehicles, vehicle parts, substructure, etc., can solve the problems of floor fracture damage, slow driving speed, economic loss, etc., achieve good safety performance, improve stability, and high safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be described below in conjunction with specific embodiments.

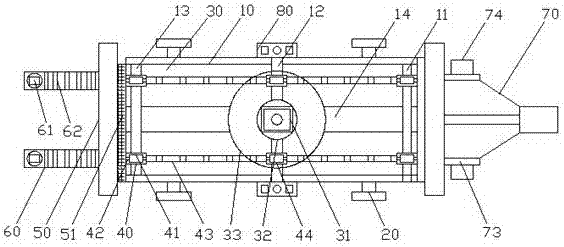

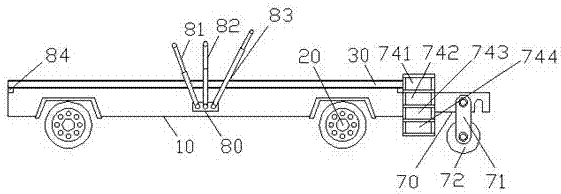

[0020] Such as Figure 1 to Figure 3 Shown is a structural schematic diagram of a special flatbed trailer for harvesting machinery according to the present invention.

[0021]A special flatbed trailer for harvesting machinery according to the present invention comprises: a car frame 10 and row wheels 20 arranged at the bottom of the car frame 10 for supporting the car frame 10, and the car frame 10 is provided with a car floor 30, a crossbeam 11, a crossbeam Two 12, crossbeam three 13 and horizontal crossbeam 14, crossbeam one 11, crossbeam two 12, crossbeam three 13 are equidistantly arranged on the car frame 10, and horizontal crossbeam 14 is positioned at the middle position of car frame 10 and is perpendicular to crossbeam one 11, crossbeam two 12 1. Crossbeam three 13 is provided with, crossbeam one 11, crossbeam two 12, and crossbeam three 13 are all symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com