A ring seat automatic positioning welding device

An automatic positioning and welding device technology, applied in auxiliary devices, welding equipment, welding equipment and other directions, can solve the problems of difficult to achieve symmetry, unstable arc forming radius, skew, etc., and achieve the effect of eliminating inaccurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

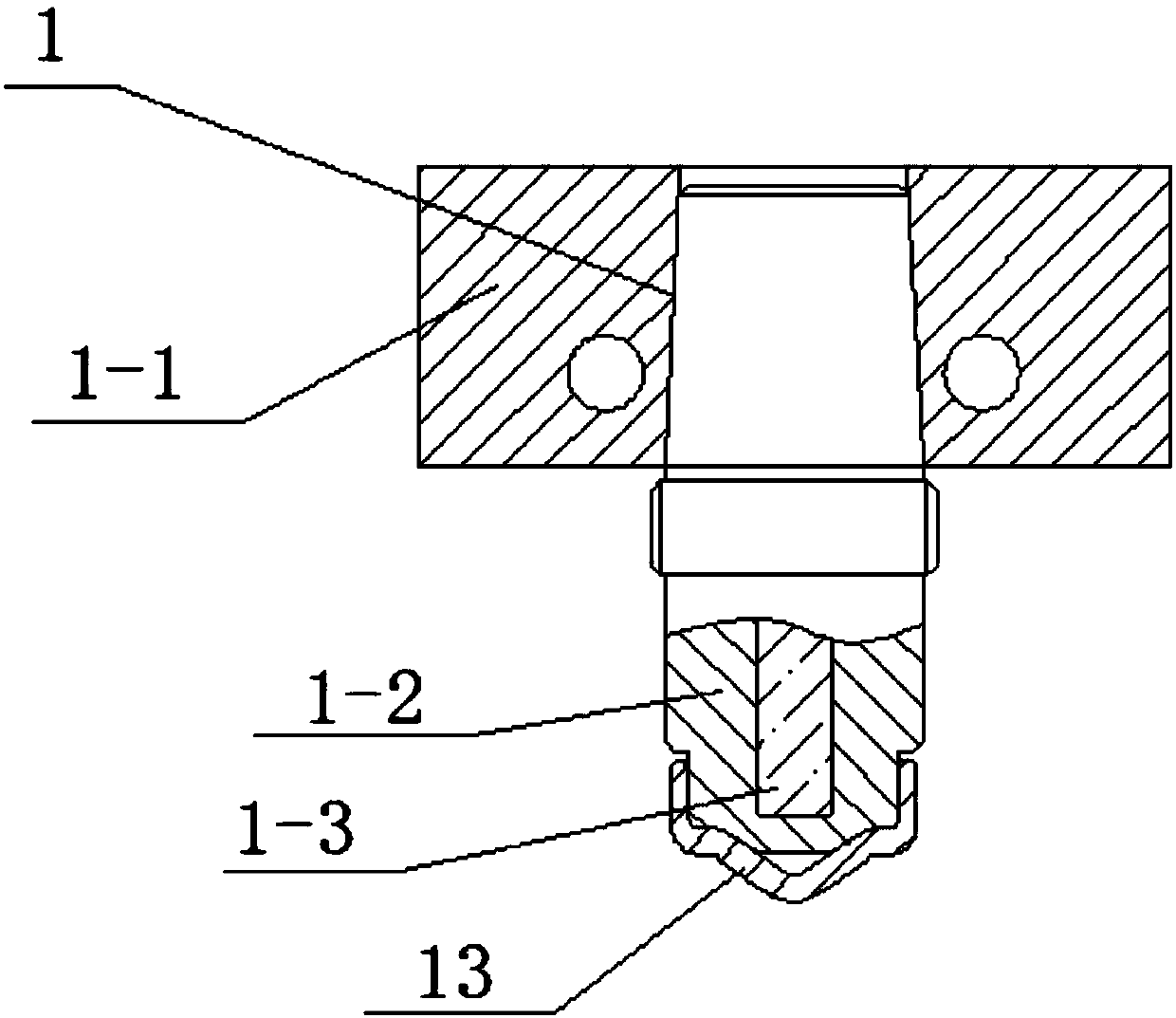

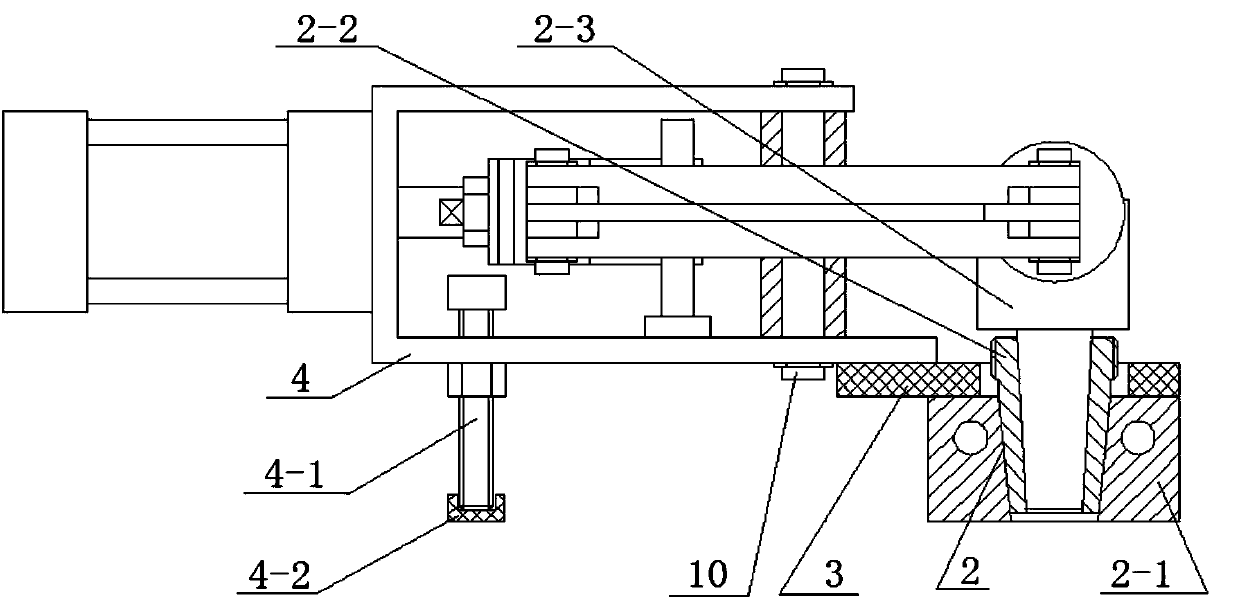

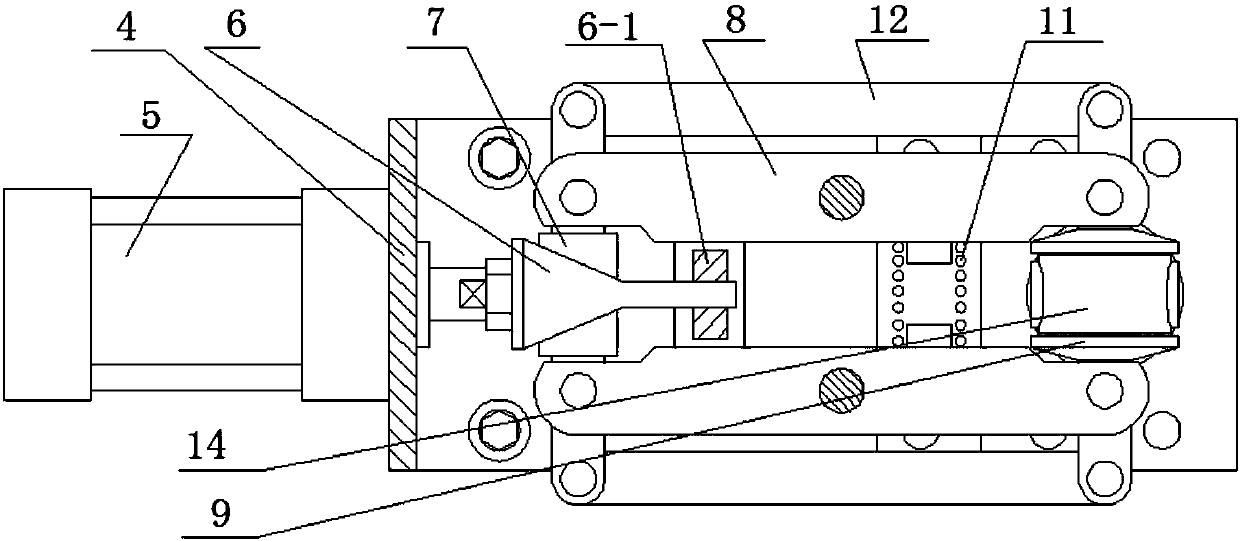

[0020] Such as figure 1 , figure 2 , image 3 A ring seat automatic positioning welding device shown includes an upper electrode 1 and a lower electrode 2, the upper electrode 1 is located directly above the lower electrode 2; the lower electrode 2 is connected to the fixture bottom plate 4 through an insulating support 3, and the A working cylinder 5 is installed on the fixture bottom plate 4, and the telescopic shaft of the working cylinder 5 is connected to the wedge head 6, and the two wedge surfaces of the wedge head 6 are connected with a symmetrical translation mechanism, and the translation mechanism includes an inclined block 7, Rocking arm 8, positioning and reinforcing head 9, long pin shaft 10, one end of the rocking arm 8 is connected to the inclined block 7, the other end of the rocking arm 8 is connected to the positioning and reinforcing head 9, and the middle of the rocking arm 8 passes through the long pin The shaft 10 is fixed on the fixture bottom plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com