Cooling structure of sand coating machine for iron mold

A technology of cooling structure and sand-covering machine, which is applied to molding machines, parts of molding machines, casting molding equipment, etc., and can solve problems such as easy wear of sealing rings and unstable operation of supporting cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

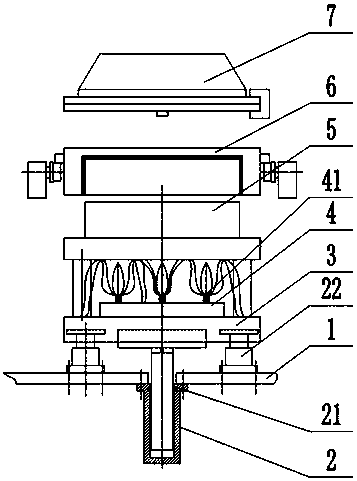

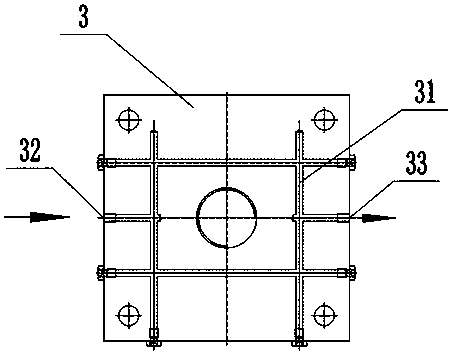

[0018] The reference signs in the drawings of the description include: mounting plate 1, supporting cylinder 2, sealing ring 21, auxiliary cylinder 22, bottom plate 3, cross flow channel 31, water inlet 32, drain 33, combustion plate 4, nozzle 41, mold 5 , sand box 6, sand shooting mechanism 7.

[0019] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0020] The cooling structure of the iron type sand coating machine in this scheme is installed on the sand coating machine. The sand coating machine is installed with a sand shooting mechanism 7, a sand box 6 and a mold 5 in sequence from top to bottom. The sand shooting end of the sand shooting mechanism 7 and the The sand box 6 is connected, and the sand box 6 and the mold 5 are detachably connected. The bottom of the mold 5 is connected with a heating device. A sealing ring 21 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com