Method for driving and controlling an electric motor

A drive control and motor technology, applied in motor control, control system, single motor speed/torque control, etc., can solve the problems of increased cost of temperature sensor components, unstable thermal conductivity, detection error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

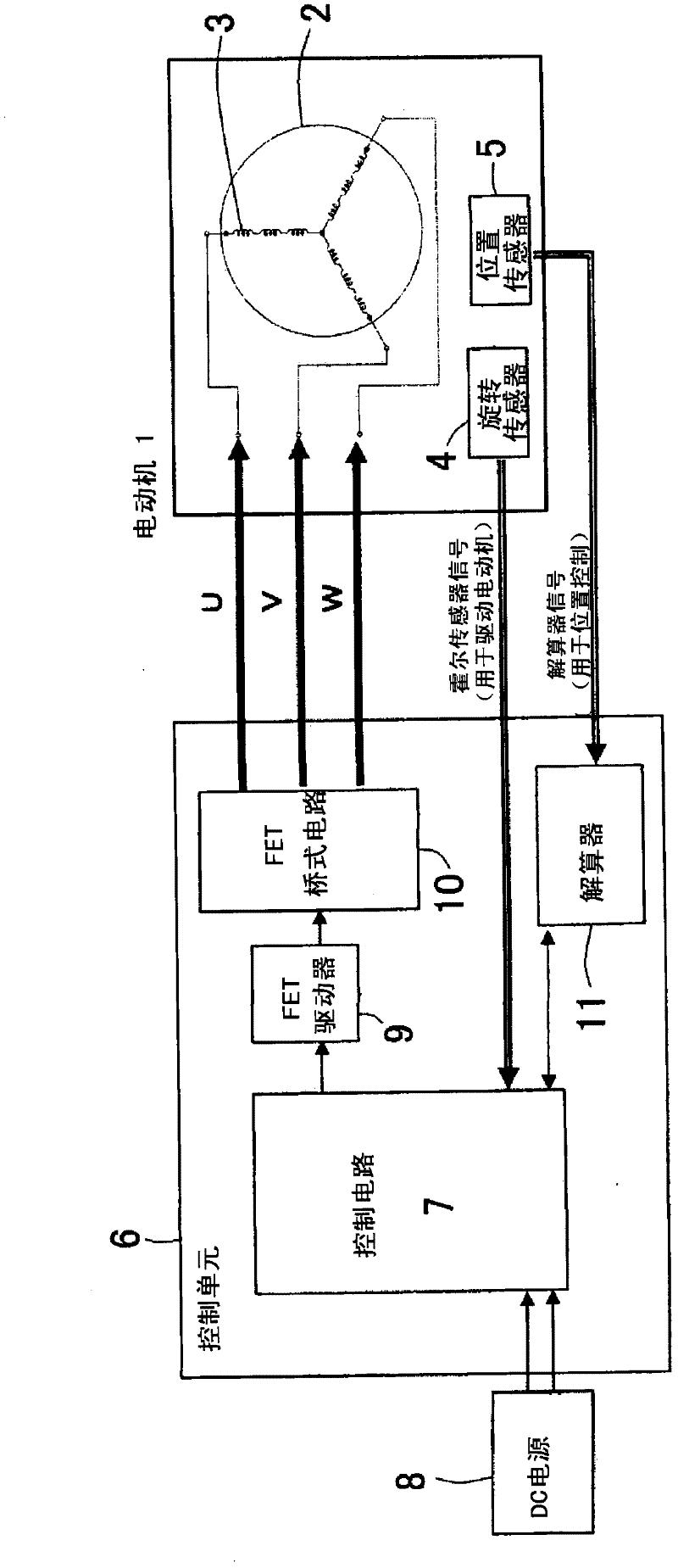

[0029] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings. In the following embodiments, as an example of a motor, an in-vehicle three-phase DC brushless motor will be explained.

[0030] First, refer to figure 1 To explain the control system of the electric motor.

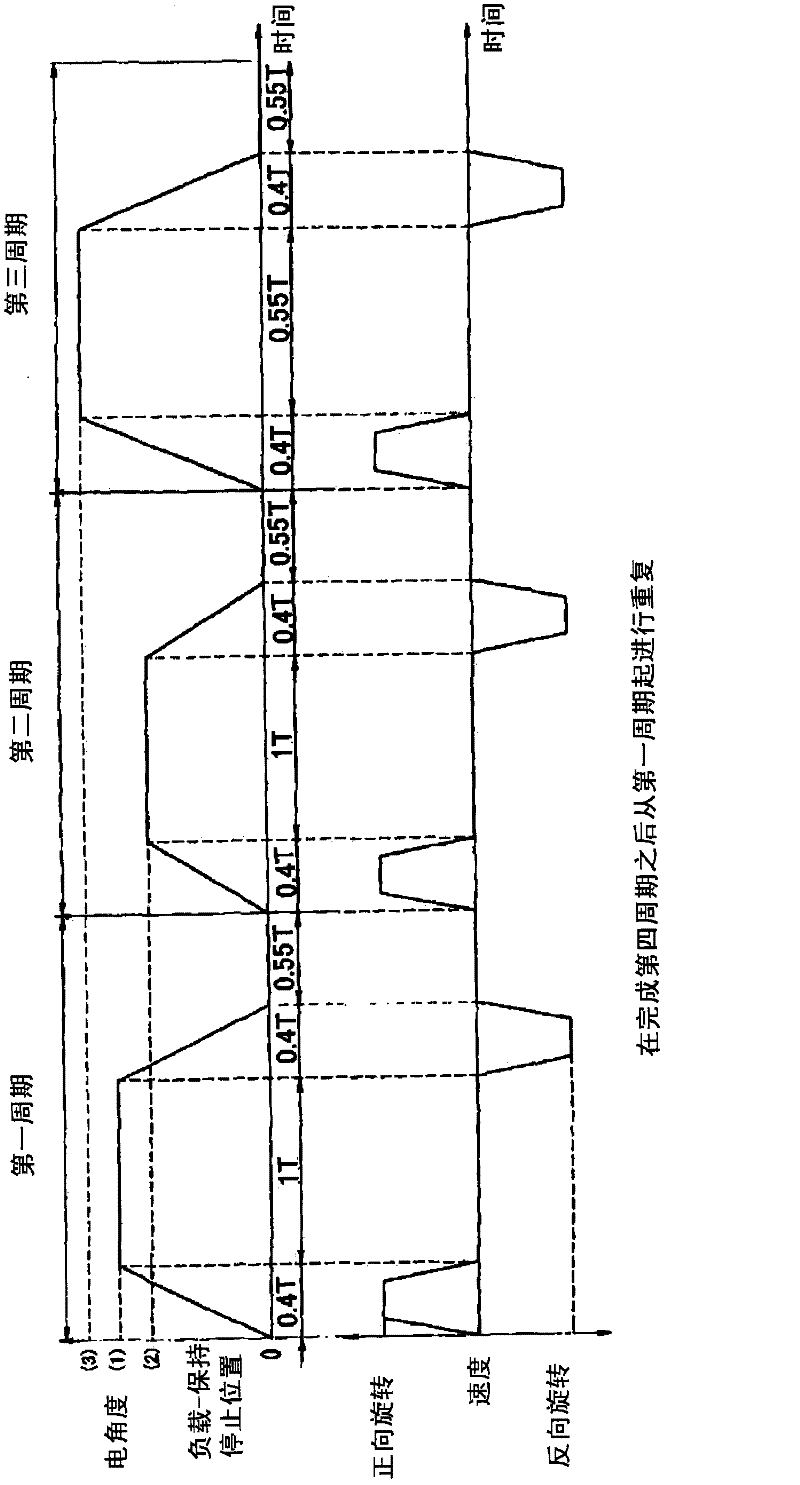

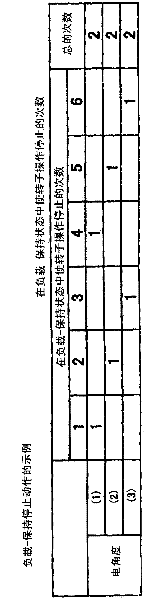

[0031] Electric motor 1 generates electrical energy to help press the clutch pedal. The electric motor 1 rotates in the normal direction or the reverse direction according to the pressing action or the returning action of the clutch pedal. Through the ball bearing screws of the auxiliary mechanism, the rotational movement of the electric motor 1 is converted into a linear movement, so that the clutch plates can be connected and disconnected. If the motor 1 is driven while the clutch pedal is pressed (in a load-holding stop state), there is a possibility that the maximum current passes through the motor coils 3 of a specific phase and these ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com