Optical method for monitoring plasma discharging glow

A discharge glow and optical monitoring technology, applied in the field of monitoring technology, can solve the problems of undeveloped plasma size and shape, and inability to know the plasma shape and absolute intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

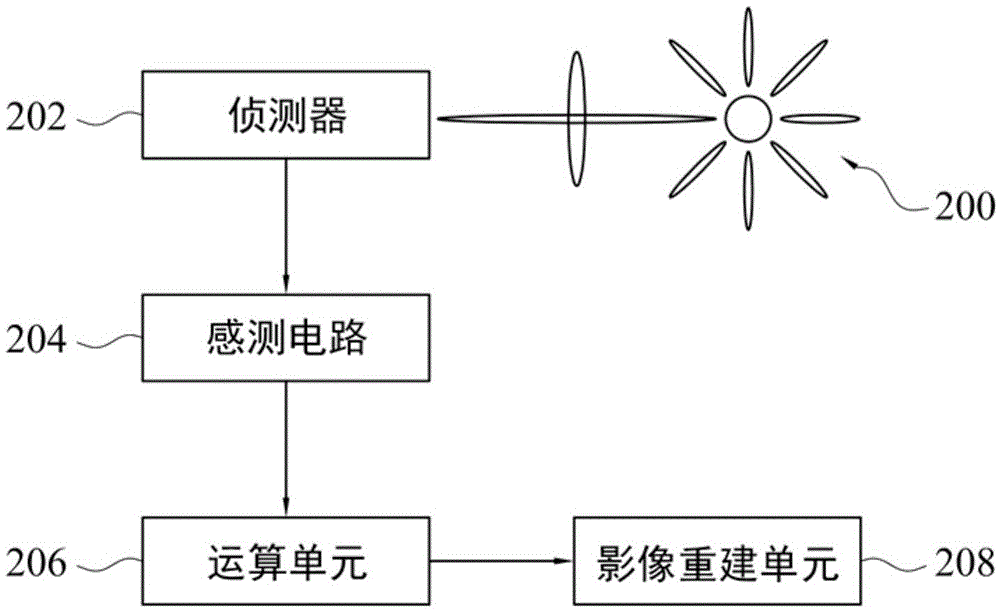

[0015] In view of the fact that there is currently no technology that can correctly evaluate the size and shape of the plasma, and there is no technology that can directly evaluate the intensity distribution of the plasma, so the present invention proposes an optical monitoring method for the plasma discharge glow, which uses an optical method. Detection of plasma discharge glow. Thereby, characteristics such as shape, size, temperature distribution, color distribution, flickering behavior, relative intensity, absolute intensity and intensity distribution of the plasma discharge glow can be evaluated effectively and quickly in a non-contact manner. Therefore, the efficacy of real-time monitoring of the plasma-treated area can be achieved. Moreover, since the present invention can use a charge-coupled device to detect the photoelectron intensity of the plasma discharge glow, the monitoring cost can be reduced.

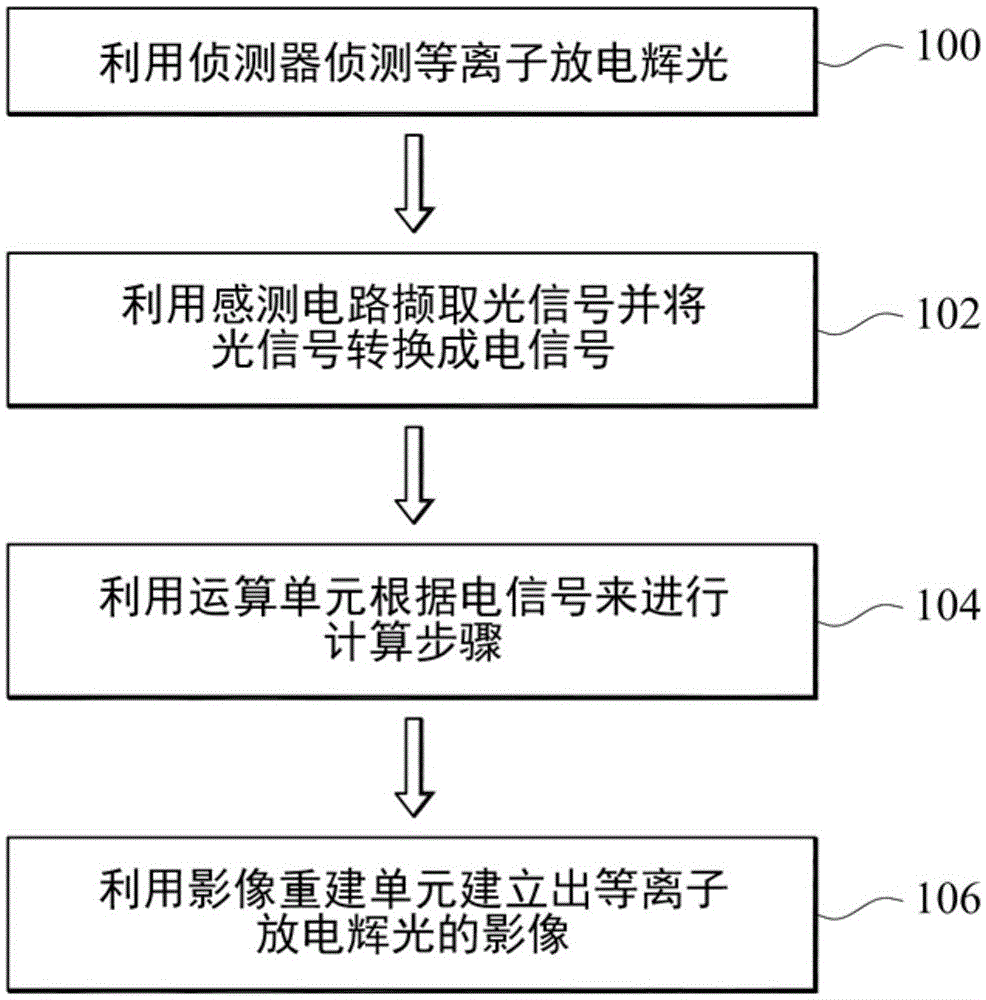

[0016] Please also refer to figure 1 and figure 2 ,in figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com