Biogas circulation desulfurization system

A desulfurization system and biogas technology, applied in the field of biogas cycle desulfurization system, can solve the problems of low desulfurization efficiency of biogas, low utilization rate of desulfurization agent, high production cost, etc., and achieve the effect of simple structure, high utilization rate and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

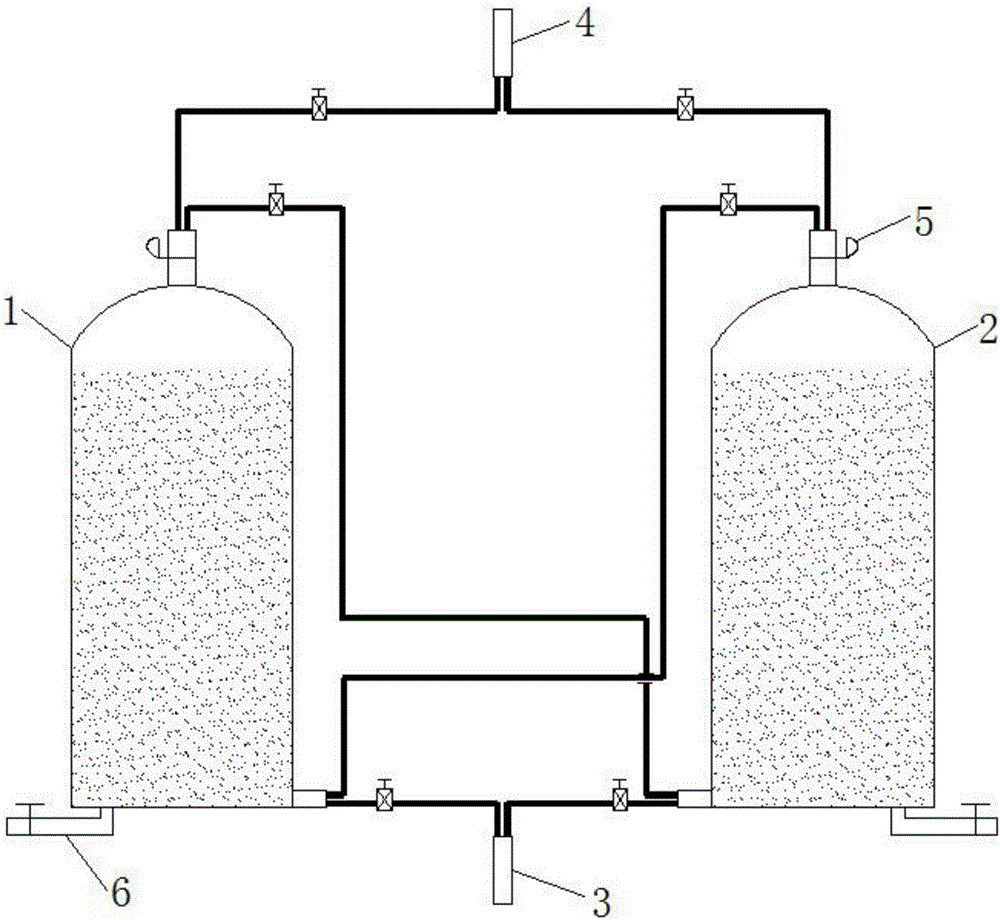

[0023] Embodiment one: if figure 1 As shown, the biogas circulation desulfurization system of this embodiment includes a first desulfurization tower 1 and a second desulfurization tower 2, the lower end side walls of the first desulfurization tower 1 and the second desulfurization tower 2 are provided with air inlets, and the top Gas outlets are all provided, and the air inlet of the first desulfurization tower 1 is connected to the gas outlet of the second desulfurization tower 2 through a pipeline, and the gas outlet of the first desulfurization tower 1 is connected to the air inlet of the second desulfurization tower 2 through a pipeline. The first desulfurization tower 1 and the second desulfurization tower 2 are respectively filled with desulfurizers.

[0024] It also includes a biogas intake main pipe 3, the air inlets of the first desulfurization tower 1 and the second desulfurization tower 2 are respectively connected to the biogas intake main pipe 3 through pipes, and...

Embodiment 3

[0032] Embodiment 3: Use the first desulfurization tower 1 and the second desulfurization tower 2 to desulfurize the biogas efficiently. solenoid valve, and close the solenoid valve on the pipeline between the gas inlet of the first desulfurization tower 1 and the gas outlet of the second desulfurization tower 2, so that the biogas that passes into the biogas inlet main pipe 3 is diverted and then introduced into the first desulfurization tower 1 and the gas outlet of the second desulfurization tower respectively. Desulfurization treatment is carried out in the second desulfurization tower 2 respectively. After the treatment, the gas outlets of the two are respectively converged into the biogas outlet main pipe 4 through pipelines, and then discharged in a concentrated manner and introduced into the subsequent packaging system.

[0033] When the biogas desulfurization process is carried out in the first desulfurization tower 1 or the second desulfurization tower 2, the moisture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com