automatic centering mechanism

A technology of automatic centering and centering, which is used in mechanical equipment, transmission control, components with teeth, etc., can solve the problems of unreliable product self-centering positioning, inability to reduce product weight, and large space volume. The effect of reducing product design space, reducing product weight and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation, structure, features and functions of the automatic centering mechanism proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

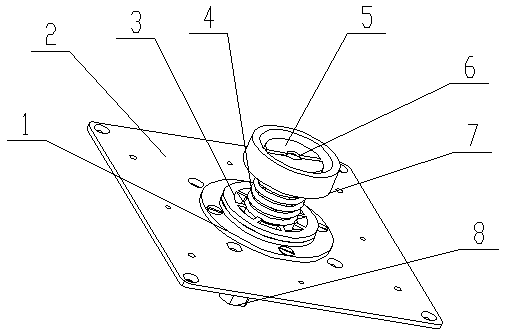

[0016] see figure 1 , the automatic centering mechanism of the present invention includes a mounting panel 2, a positioning base plate 1, and a central shaft 8, wherein: the central shaft 8 runs through the middle of the mounting panel 2, the mounting panel 2 is connected with a positioning base plate 1, and the upper part of the positioning base plate 1 is connected to There is a spring base 3, the spring base 3 is equipped with a spring 4, the spring 4 is sleeved on the outside of the central shaft 8, the spring 4 top is equipped with an adjustment nut 5, and the adjustment nut 5 is provided with a fastening nut 7 outside. The spring base 3 and the positioning base plate 1 adopt spherical surfaces to cooperate, the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com