A secondary purification device for automobile exhaust and its working process

A secondary purification and automobile exhaust technology, which is applied in the direction of exhaust devices, noise reduction devices, machines/engines, etc., to achieve the effects of strong applicability, stable high-pressure operation, and uniform discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

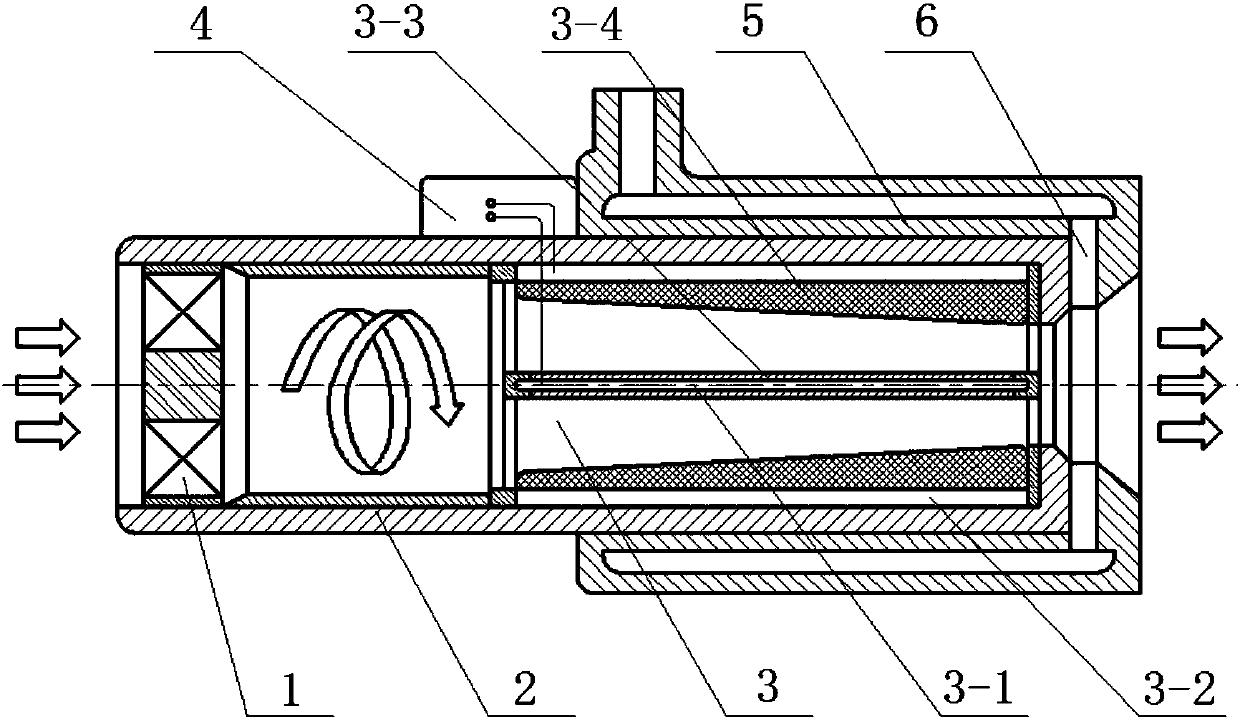

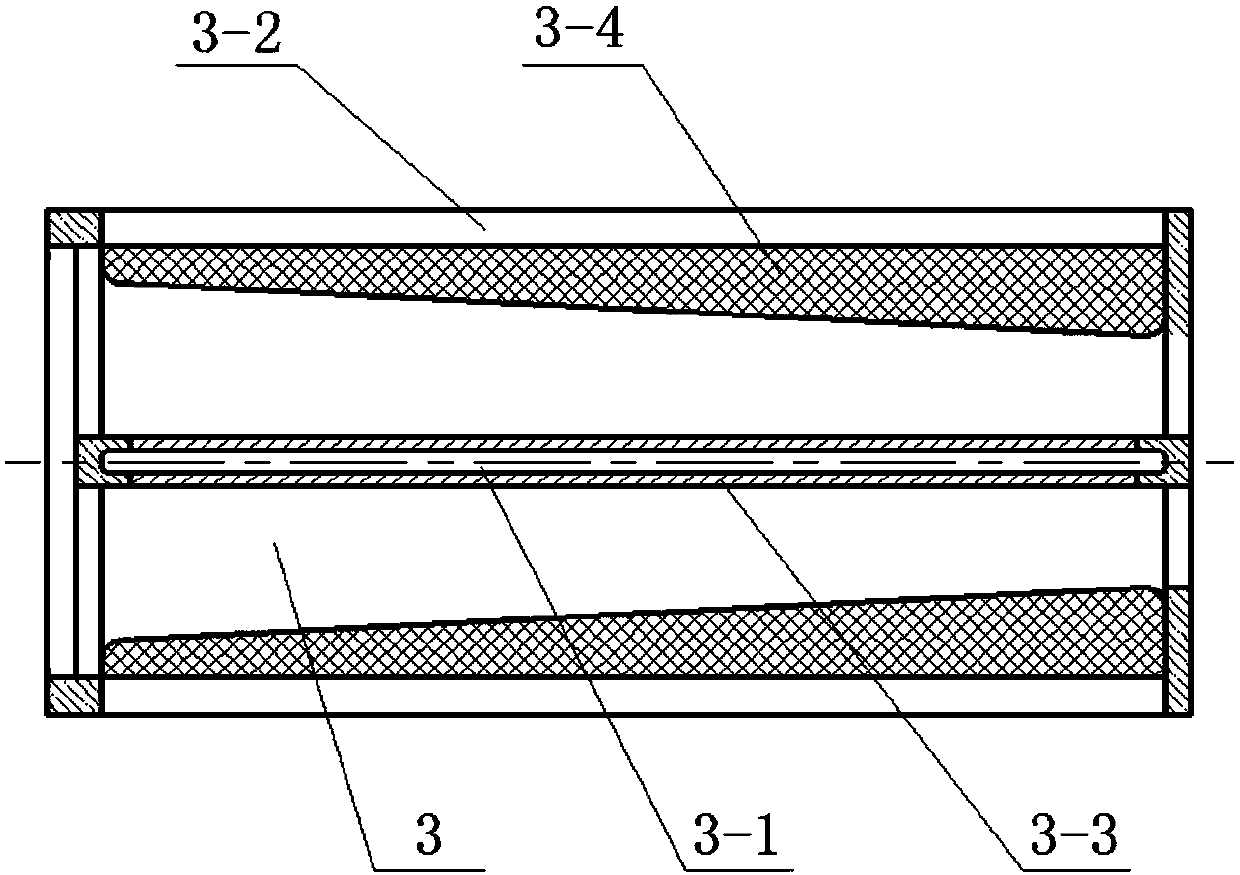

[0035] Please refer to Figure 1 to Figure 9 As shown, the automobile exhaust secondary purification device of the present invention includes a gas cyclone 1, an exhaust conduit 2, a wire-pipe plasma reactor 3, a power supply box 4, an exhaust gas treatment liquid diversion chamber 5, and a tangential swirl tank 6; The gas cyclone 1 is installed at the inlet section of the exhaust duct 2, and the outer wall of the gas cyclone 1 is in contact with the inner wall of the exhaust duct 2; a line-tube plasma reactor 3 is installed in the passage of the exhaust duct 2, and the line The outer wall of the tubular plasma reactor 3 is in contact with the inner wall of the exhaust duct 2 , and the end of the line tube plasma reactor 3 is in contact with the bottom of the exhaust duct 2 . The outer surface of the exhaust conduit 2 is installed together with the tail gas treatment liquid diversion chamber 5, the inlet of the tail gas treatment liquid diversion chamber 5 can be connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com