Unequal-speed impeller mechanism and compressor and expansion mechanism including same

A technology of expansion mechanism and impeller, applied in the direction of machine/engine, blade supporting element, mechanical equipment, etc., can solve the problems of unreasonable structure, inability to solve multi-level linkage, limited application and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

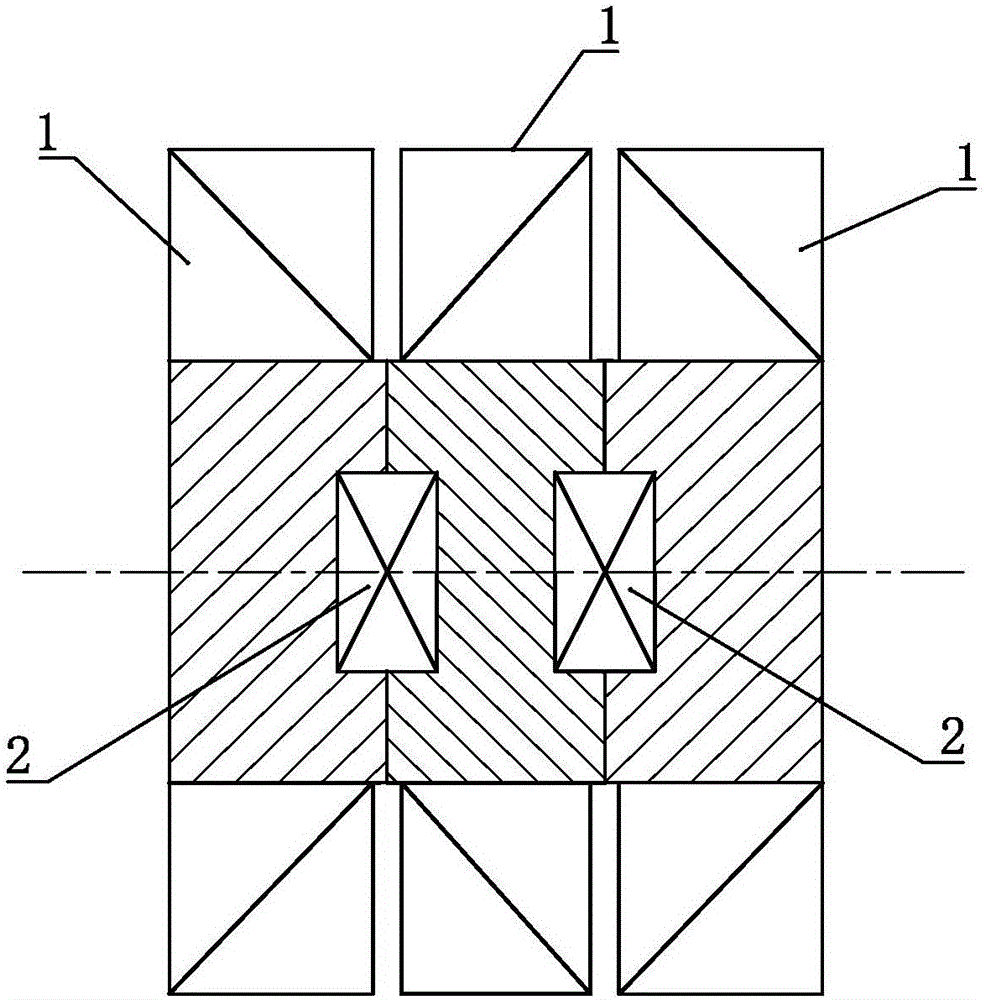

[0073] Such as figure 1 The variable-speed impeller mechanism shown includes three impellers 1 , and the three impellers 1 are arranged correspondingly in sequence, and two adjacent impellers 1 are set in linkage through the transmission device 2 .

[0074] See attached figure 1 , when including more than two corresponding impellers 1 in sequence, the transmission device 2 can be arranged between each group of adjacent impellers 1, so as to conveniently realize multi-stage linkage, and at the same time realize each of the The rotating speed of the impeller 1 is not equal to improve the performance of the impeller.

[0075] In this embodiment, three correspondingly arranged impellers 1 are provided. As a convertible embodiment, the number of impellers 1 included in the different-speed impeller mechanism can be set according to actual needs. When it includes three or more The impeller 1 can be as figure 1 As shown, all the impellers 1 are arranged correspondingly in sequence,...

Embodiment 2

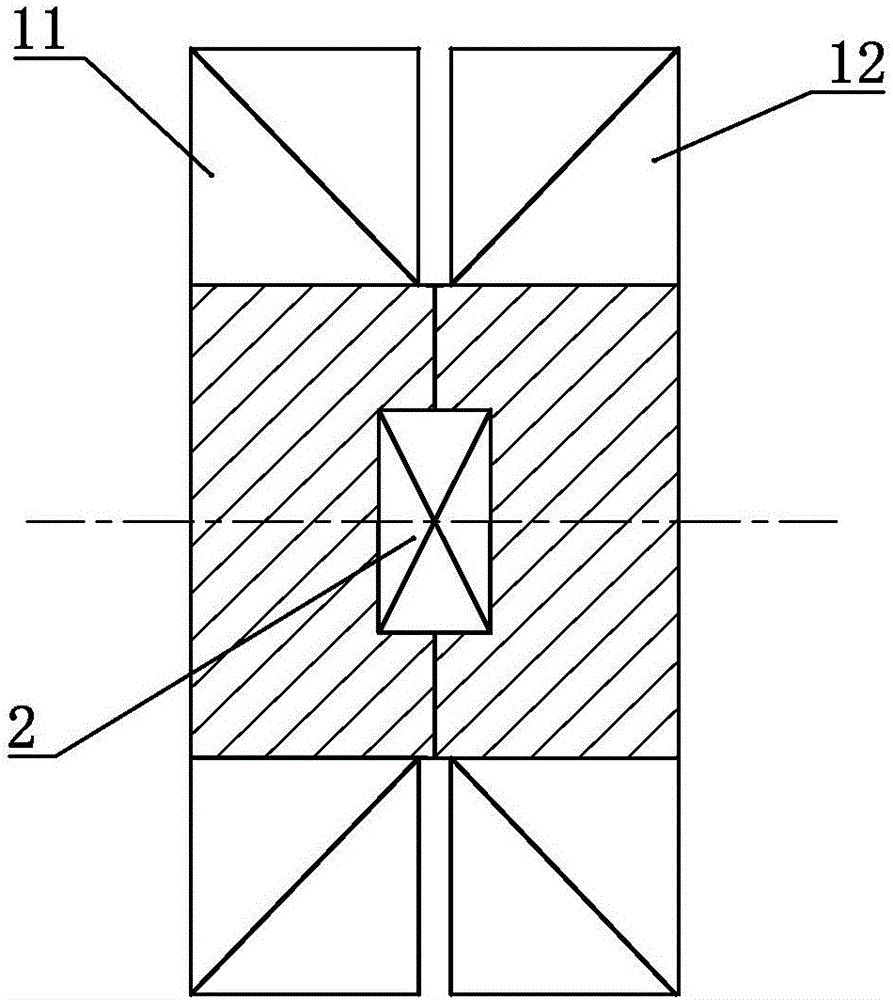

[0077] Such as figure 2 The difference between the variable speed impeller mechanism shown in Embodiment 1 is that the variable speed impeller mechanism includes two impellers 1, which are respectively set as the moving impeller A 11 and the moving impeller B 12, and the moving impeller A 11 Correspondingly arranged with the moving impeller B 12 to form a working stage, the moving impeller A 11 and the moving impeller B 12 are directly set in linkage through the transmission device 2 .

[0078] As an alternative embodiment, the moving impeller A 11 and the moving impeller B 12 can also be set in linkage indirectly through the transmission device 2, for example, between the moving impeller A 11 and the transmission device 2 or in the Another transmission mechanism is also arranged between the moving impeller B 12 and the transmission device 2 .

Embodiment 3

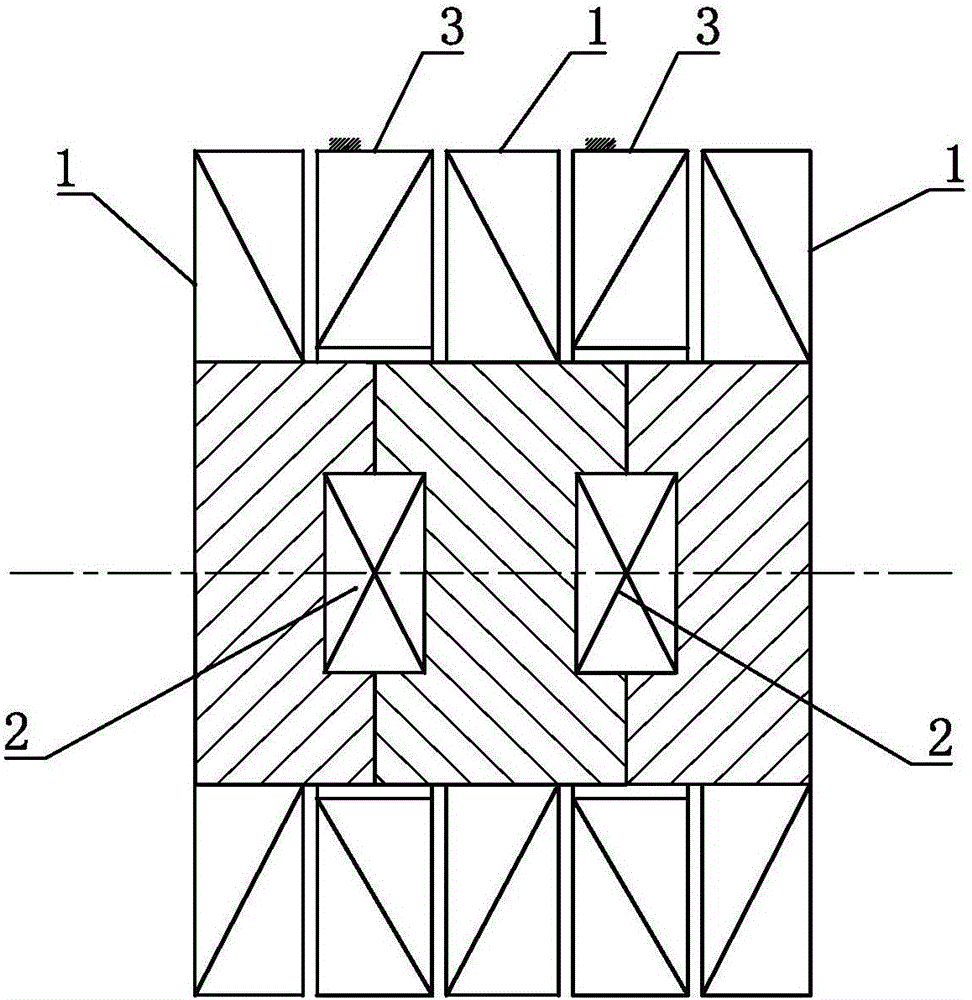

[0080] Such as image 3 In the shown variable speed impeller mechanism, on the basis of Embodiment 1, the speed change device 2 is set as a forward speed change device so that the two impellers 1 that are set in linkage through it rotate in the same direction. A stationary impeller 3 is arranged between the two impellers 1 set in linkage with the speed changer.

[0081] As an alternative implementation manner, the stationary impeller 3 in this embodiment may not be provided.

[0082] As a changeable embodiment, the speed change device 2 can also be changed to a reverse speed change device so that the rotation directions of the two impellers 1 set in linkage are opposite. At this time, the stationary impeller 3 does not need to be provided. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com