Integral column formwork based on 3d printing and used for concrete pouring and column pouring method

A 3D printing, concrete technology, applied in the direction of formwork/formwork/work frame, architecture, building structure, etc., can solve problems such as reducing construction efficiency, and achieve the effect of improving construction efficiency, low cost and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

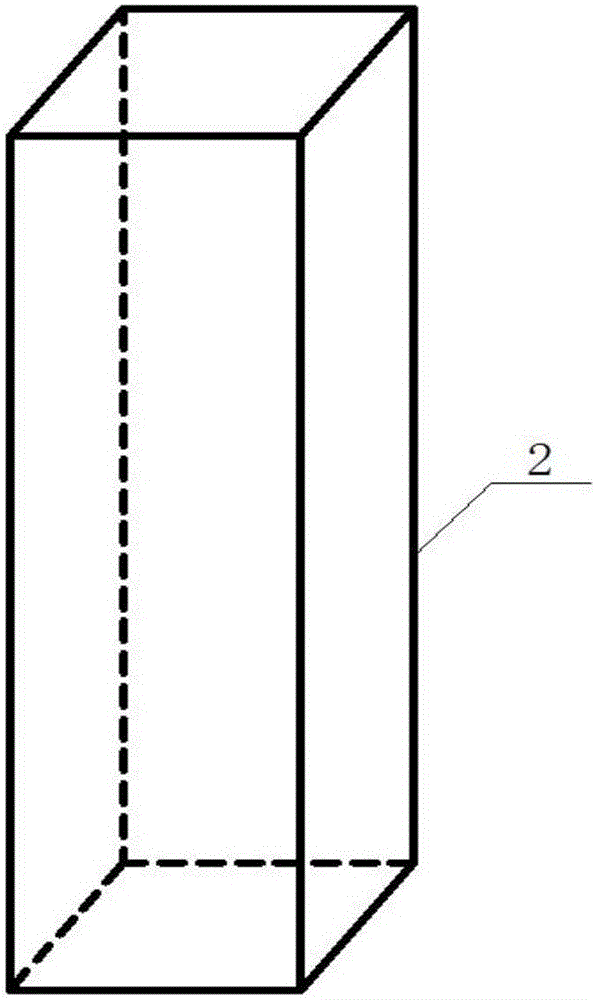

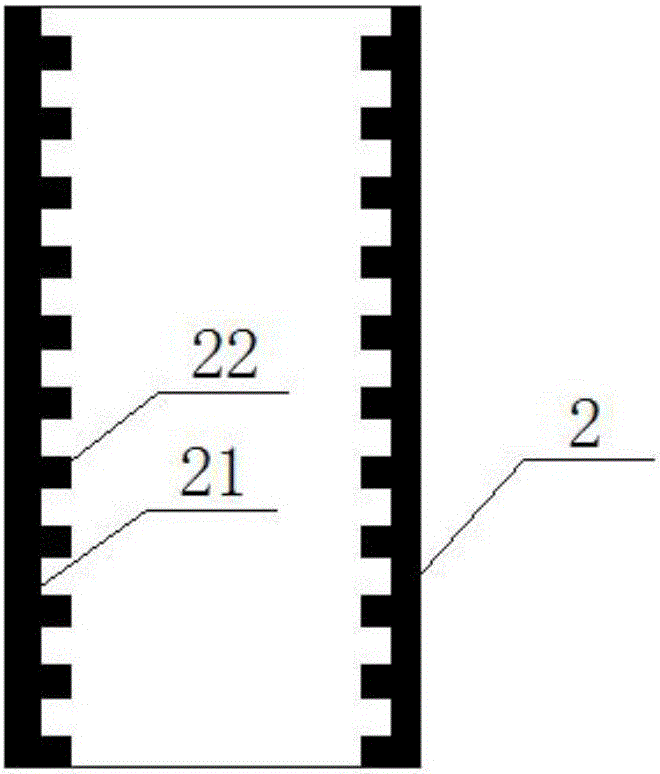

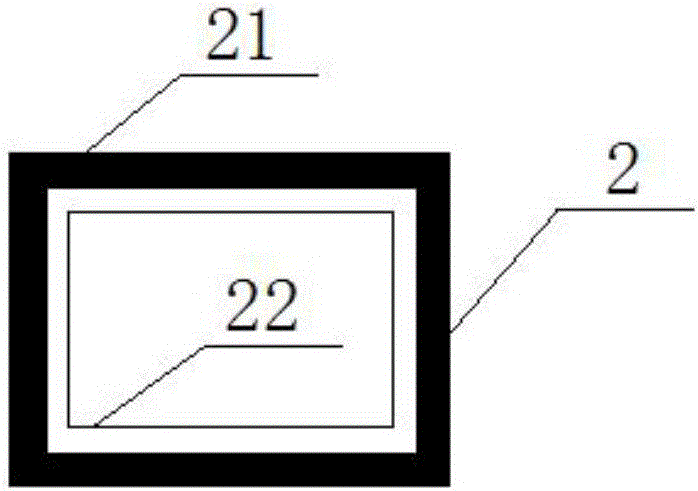

[0028] Such as figure 1 As shown, the integrated column template 2 of this embodiment is a tubular structure printed by 3D, and its longitudinal section is as follows figure 2 As shown, its cross-section is shown as image 3 shown. The printed tubular structure consists of a tubular wall 21 and reinforcing ribs 22 .

[0029] In this embodiment, the reinforcing ribs 22 are arranged on the inner side of the tube wall 21. The reinforcing ribs 22 are continuously distributed in an annular shape and arranged circumferentially around the inner side of the tube wall 21. On the whole, the reinforcing ribs 22 are multi-channel, along the axial direction of the tube wall 21. Arranged in sequence. As another implementation manner, the reinforcing ribs are helically arranged.

[0030] The reinforcing ribs 22 can also be provided with reinforcing ribs on the outside of the tube wall 21 or both inside and outside. If a larger wall thickness is adopted, the reinforcing ribs may not be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com