Improved variable-section hollow square pile

A technology of hollow square piles with variable cross-sections, which is applied to sheet pile walls, buildings, and foundation structure engineering. It can solve problems such as loss of sealing effect, heavy weight, and weak elastic force, so as to improve connection stability and bending resistance. Ability, the effect of improving positioning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

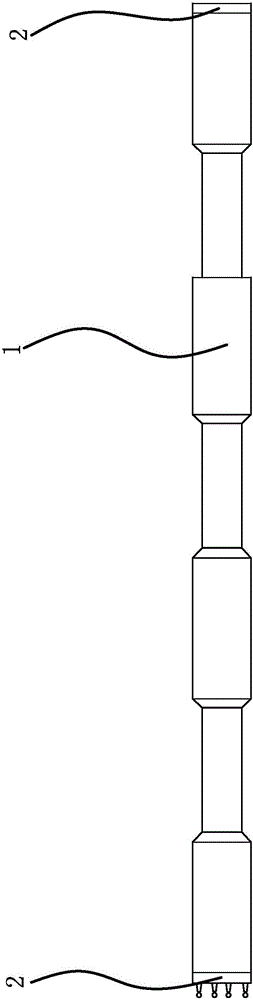

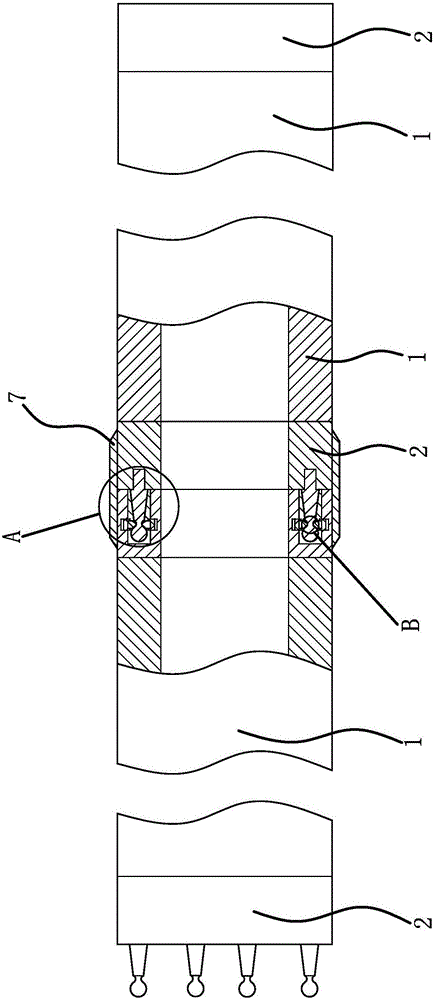

[0032] Such as figure 1 , figure 2 , image 3 As shown, an improved variable cross-section hollow square pile includes a tubular pile body 1, both ends of the pile body 1 are fixedly connected with a ring-shaped metal end plate 2, and the end plate 2 at one end of the pile body 1 is circumferentially opened There are a number of plug holes 3, and a number of plug pins 4 are fixedly connected to the side of the end plate 2 at the other end. The plug pins 4 include a cylindrical sealing portion 41 and a spherical fixing portion 42 located at the free end of the sealing portion 41. The fixing portion An annular groove 43 is formed between the outer side surface of 42 and the end surface of the sealing portion 41, and two halves of annular fixing plate 5 are connected in the insertion hole 3, and the recesses of the two fixing plates 5 are opposed to each other. When the inserting post 4 of one pile 1 is inserted into the inserting hole 3 of the other pile 1, the edges of the notch...

Embodiment 2

[0035] The structure of the modified variable cross-section hollow square pile is basically the same as that of the first embodiment, the difference lies in the following Figure 5 , Image 6 As shown, the hollow square pile also includes a steel hoop plate 9. The inner wall of the steel hoop plate 9 has a plurality of clamping ribs 91 circumferentially arranged along the axial direction of the steel hoop plate 9. The outer wall of the end plate 2 is provided with a number of clamping grooves 22 in the circumferential direction. When the insertion post 4 of one pile 1 is inserted into the insertion hole 3 of the other pile 1, the steel hoop plate 9 is sleeved in On the two end plates 2, and the clamping rib 91 is clamped in the clamping groove 22, the structure uses the steel hoop plate 9 to hold the two end plates 2 tightly, wherein the clamping rib 91 is clamped in the clamping groove 22, The steel hoop plate 9 strengthens the two piles 1 and improves the bending resistance, w...

Embodiment 3

[0037] The structure of the modified variable cross-section hollow square pile is basically the same as that of the first embodiment, the difference lies in the following Figure 7 As shown, the tensioning member includes a plurality of tensioning blocks 10, and a plurality of sliding grooves 101 are provided on the inner wall of the insertion hole 3 in the circumferential direction. The length direction of the plurality of sliding grooves 101 is the same as the axial direction of the insertion hole 3. The bottom surface of 101 is the pushing surface 102, and the pushing surface 102 is inclined toward the center of the insertion hole 3 toward one end of the opening of the insertion hole 3, the side surface of the tension block 10 is an inclined surface, and the tension block 10 is slidably connected to In the sliding groove 101, and the inclined surface of the tension block 10 is in contact with the pushing surface 102 of the sliding groove 101, a positioning groove 103 is provi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap