Sewing machine provided with flexible shaft

A technology of sewing machine and sewing machine head, which is applied in the direction of sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of limited application range of flatbed sewing machines, difficulty in automatic upgrade, and failure to adopt, etc., to achieve flexible and changeable knitting positions, manufacturing Low cost and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention provides a flexible shaft sewing machine. In order to make the objectives, technical solutions and effects of the present invention clearer and clearer, the present invention will be described in further detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

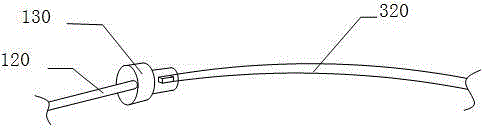

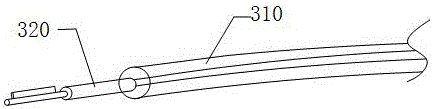

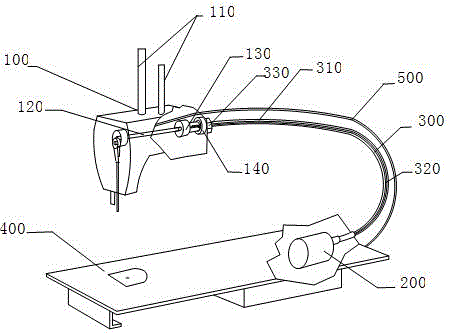

[0022] Such as figure 1 with figure 2 The shown flexible shaft sewing machine includes a sewing machine head 100 provided with a knitting mechanism and a spindle motor 200 for driving the knitting mechanism of the sewing machine head. The sewing machine head 100 is a flat car sewing machine head, and the knitting mechanism of the sewing machine head is a knitting mechanism of a flat car sewing machine. The flat car sewing machine has the widest application range and is suitable for sewing and processing a variety of fabrics. The flexible shaft sewing machine with this head brings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com