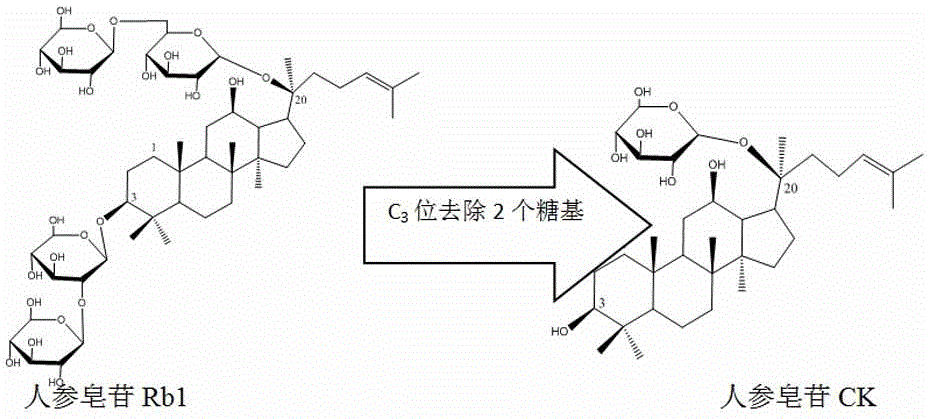

Method for massively producing ginsenoside CK by catalyzing protopanaxadiol ginsenoside through enzyme

A technology for enzymatically catalyzing diols and ginsenosides, applied in the field of biochemical industry, can solve the problems of inability to scale up large-scale production and low catalytic efficiency, and achieve the effects of improved catalytic effect, high yield and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

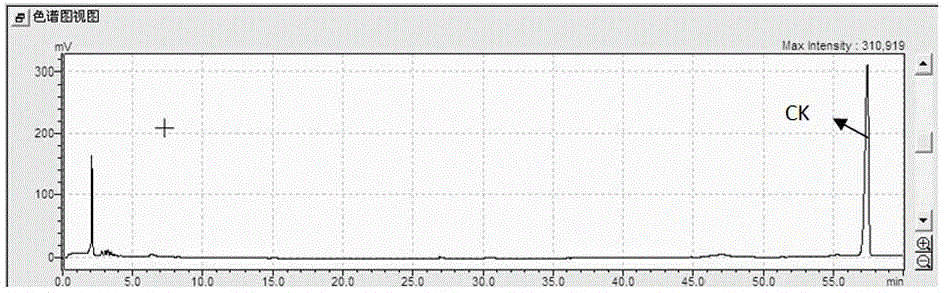

Embodiment 1

[0026] Add 60L volume, pH 5, containing 1Mm Ca 2+ Ionic phosphate buffer, then add 3kg of ginsenoside Rb1 with a purity of 85% (impurities are other types of ginsenosides or polysaccharides), pass N 2 , the ventilation flow rate is 50 L / min, and lasts for 5 minutes, then stops the ventilation and starts the heating-in-line sterilization, and the sterilization condition is 121°C, and maintains for 20 minutes. After cooling down to below room temperature, add pectinase: cellobiase 6:4 compound enzyme 2kg, and 20g heteropoly acid H 3 PW 12 o 40 ·5H 2 O. Keep the temperature of the fermenter at 25° C., the stirring speed at 200 rpm, and catalyze the reaction for 96 hours. After the reaction, put all the liquid in the container and let it stand for 12 hours, discard the supernatant, add phosphate buffer to wash several times, then add water:ethyl acetate to the precipitate for extraction, repeat the extraction three times, and collect The organic phase extract was concentrate...

Embodiment 2

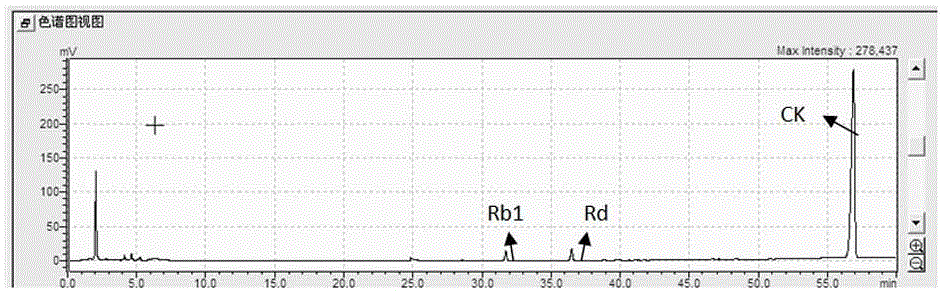

[0029] It is 200L, pH is 7, contains 4mM Ca 2+ Ionic phosphate buffer, then add 30kg of ginsenoside Rd with a purity of 90% (impurities are other types of ginsenosides or polysaccharides), pass N 2 , the ventilation flow rate is 150 L / min, and lasts for 5 minutes, then stops the ventilation and starts to heat in-line sterilization, the sterilization condition is 121°C, and maintains for 20 minutes. After cooling down to below room temperature, add pectinase: 25kg of compound enzyme with cellobiase ratio of 8:2, and 10g of heteropolyacid H 4 SiW 12 o 40 18H 2 O. Keep the temperature of the fermenter at 40°C, the stirring speed at 200rpm, and catalyze the reaction for 120h. After the reaction, put all the liquid in the container and let it stand for 12 hours, discard the supernatant, add phosphate buffer to wash several times, then add water:ethyl acetate to the precipitate for extraction, repeat the extraction three times, and collect The organic phase extract was concent...

Embodiment 3

[0031] It is 300L that volume is added in the full-automatic fermentor of 500L, pH is 9, contains the phosphate buffer solution of 5mM Ca2+ ion, adds the ginsenoside Rb2 (impurity is other types of ginsenosides or polysaccharides), through N 2 , the ventilation flow rate is 200 L / min, and lasts for 5 minutes, then stops the ventilation and starts to heat in-line sterilization, the sterilization condition is 121°C, and maintains for 20 minutes. After cooling down to below room temperature, add pectinase: cellobiase 9:1 compound enzyme 30kg, and 40g heteropolyacid H 3 FeW 12 o 40 28H 2 O. Keep the temperature of the fermenter at 50°C, the stirring speed at 200rpm, and catalyze the reaction for 120h. After the reaction, put all the liquid in the container and let it stand for 12 hours, discard the supernatant, add phosphate buffer to wash several times, then add water:ethyl acetate to the precipitate for extraction, repeat the extraction three times, and collect The organic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com