Thread seal tape roll core action device and work method thereof

A raw material tape and winding core technology, applied in the field of raw material tape winding core action device, can solve the problems of low production efficiency and achieve the effects of mechanical automation, reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

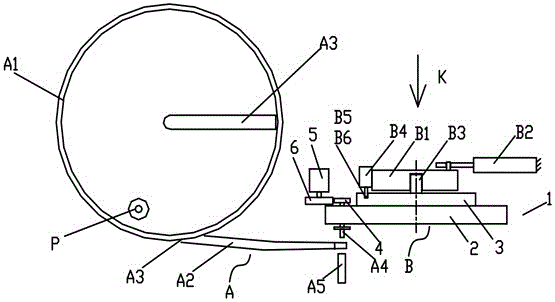

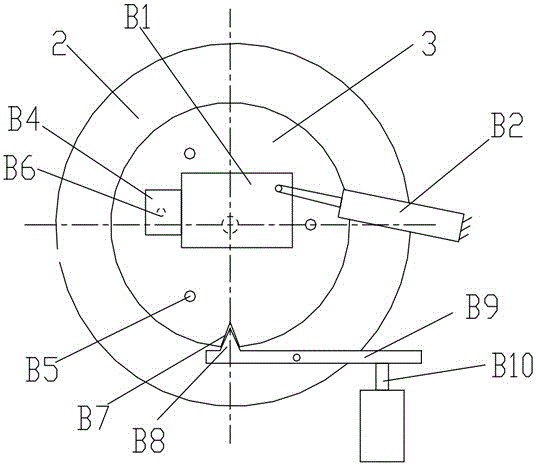

[0018] The raw material belt winding core action device of the present invention includes a body 1 and an outer turntable 2 arranged on the body 1, and a coaxial middle turntable 3 fixedly connected with the outer turntable 2, and a raw material belt is arranged on the side of the outer turntable 2 The feeding driving action mechanism A is used for feeding the winding core P, and the raw material tape turntable driving action mechanism B is provided on the rear side of the intermediate turntable to drive and rotate the turntable of the winding core. The diameter of the middle turntable 3 is seventy-five-fifths of the diameter of the outer turntable 2, and this size design makes the best effect of torque and torque.

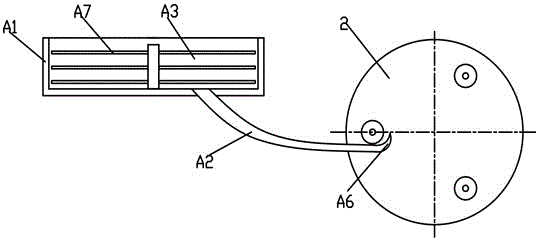

[0019] Further, in order to design rationally, the above-mentioned raw material belt feeding driving mechanism A includes a material storage tray A1 arranged on the side of the outer turntable 2 and a conveying track A2 arranged on the side of the lower side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com