Ink supply system capable of performing positive pressure cleaning and negative pressure ink jetting and printer thereof

A printer and ink supply technology, which is applied in printing and other fields, can solve problems such as low reliability and complexity, and achieve the effects of ensuring reliability, reducing corresponding expenses, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

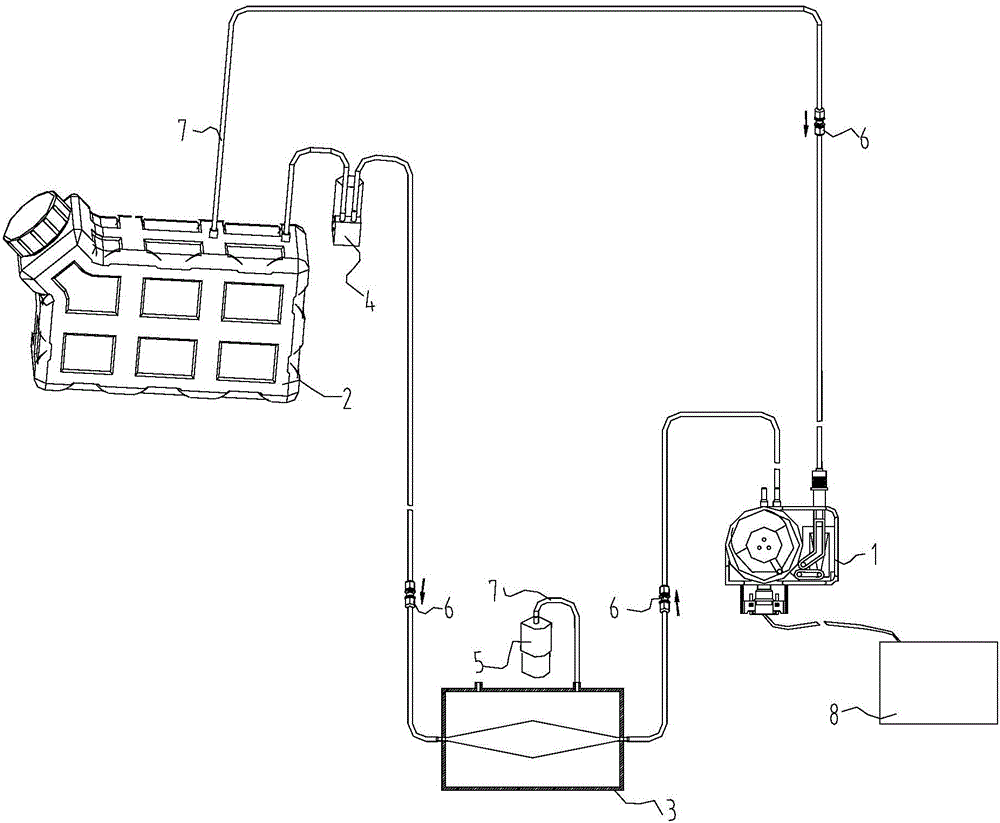

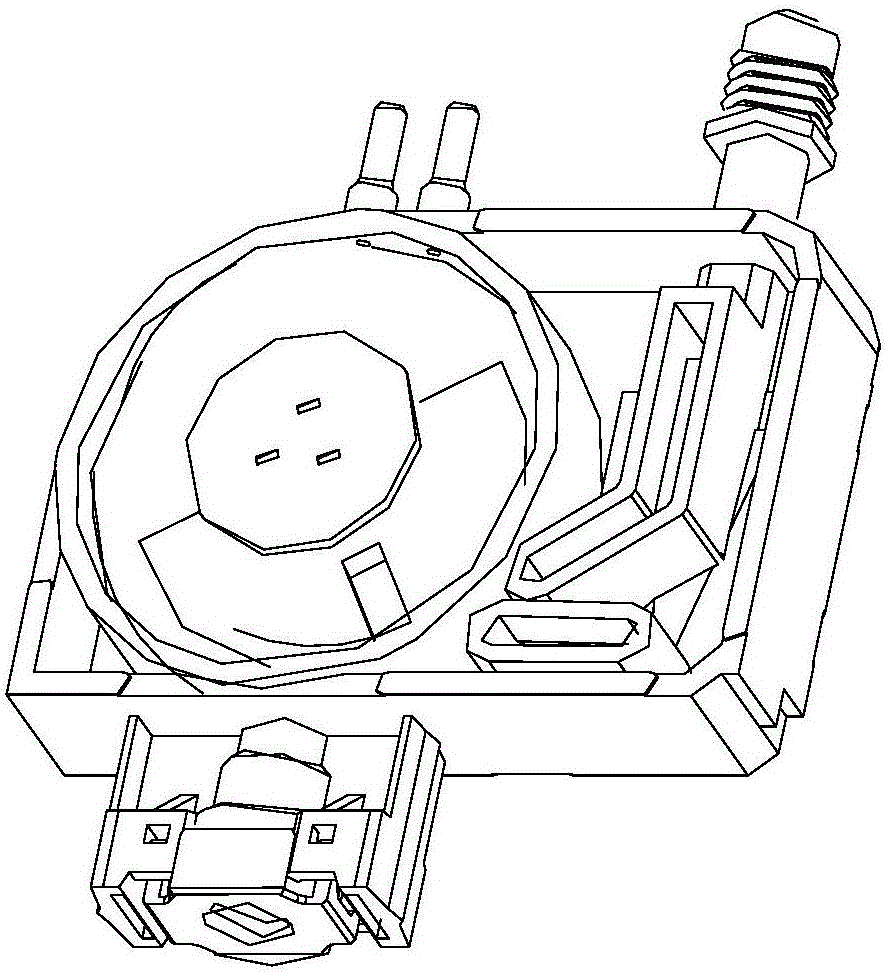

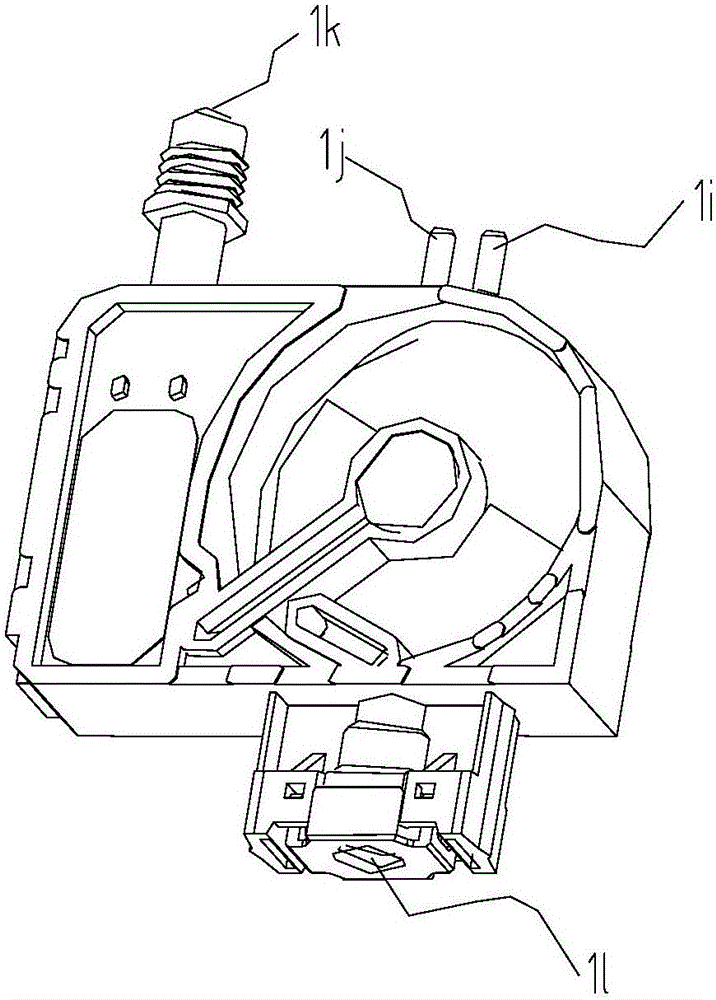

[0049] refer to Figure 1-5: Large-capacity ink bag 1, including ink bag main body 1a, small plastic disc 1b, first spring 1c, plastic boss 1d, rubber seal 1e, large plastic disc 1g, second spring 1h, exhaust outlet 1i, Pressurized water inlet 1j, large-capacity film chamber 1f, upper water inlet 1k, and ink bag water outlet 1l. One end of the PVC pipe is connected to the exhaust outlet of the ink sac, and the other end of the PVC pipe is sealed with a matching plastic plug; the pressurized water inlet 1j of the ink sac is connected to the water outlet 3b2 of the sealed ink cartridge, and a one-way valve is arranged in the middle.

[0050] Ink storage bottle 2, described ink storage bottle 2 is provided with bottle cap 2A that can be opened and filled with ink, ink pouring inlet 2a, first water outlet 2b, second water outlet 2c are set on described ink storage bottle 2, The ink pouring port 2a is used to pour bottled ink, the first water outlet 2b is connected with the upper ...

Embodiment 2

[0058] Such as Figure 7-9 The difference between this embodiment and embodiment 1 is that the ink bag has 2 channels, that is, one ink bag integrates the 2 ink bags of embodiment 1, and there are 2 pressurized water inlets correspondingly , 2 pressurized exhaust outlets, 2 large-capacity film chambers, the working principle and mode of operation are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com