Sheet film laminating machine

A laminating machine and thin plate technology, which is applied in the field of thin plate laminating technology equipment, can solve the problems of inability to achieve intelligent refueling and laminating points, waste of materials and labor, and inability to be fully universal, so as to improve production capacity and efficiency, and bond The effect of high positioning accuracy and stable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be fully described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

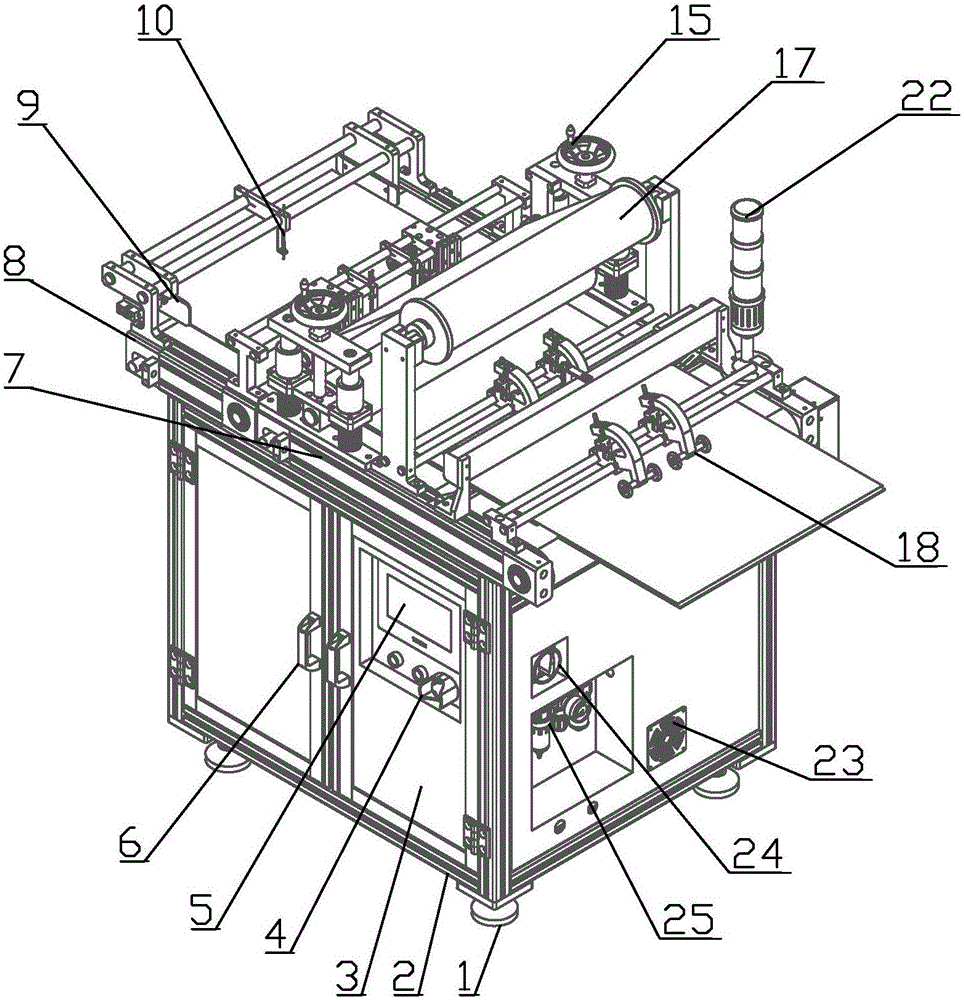

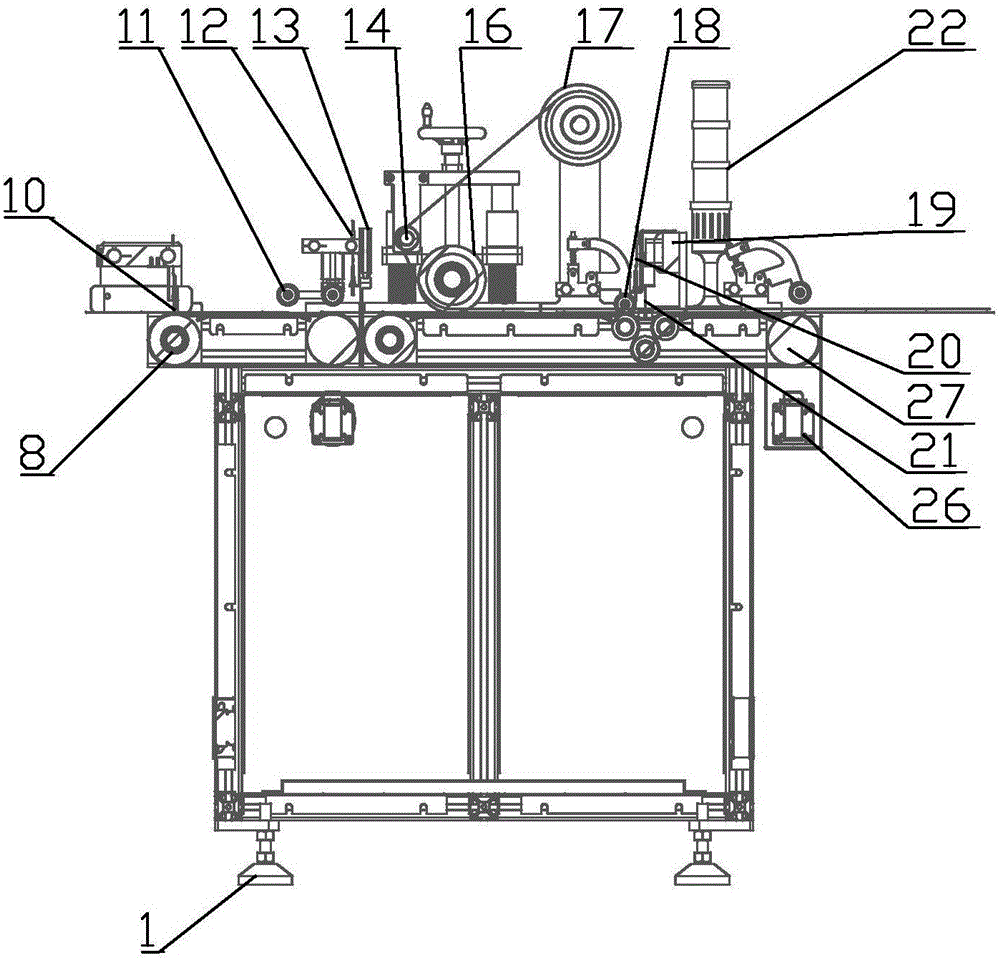

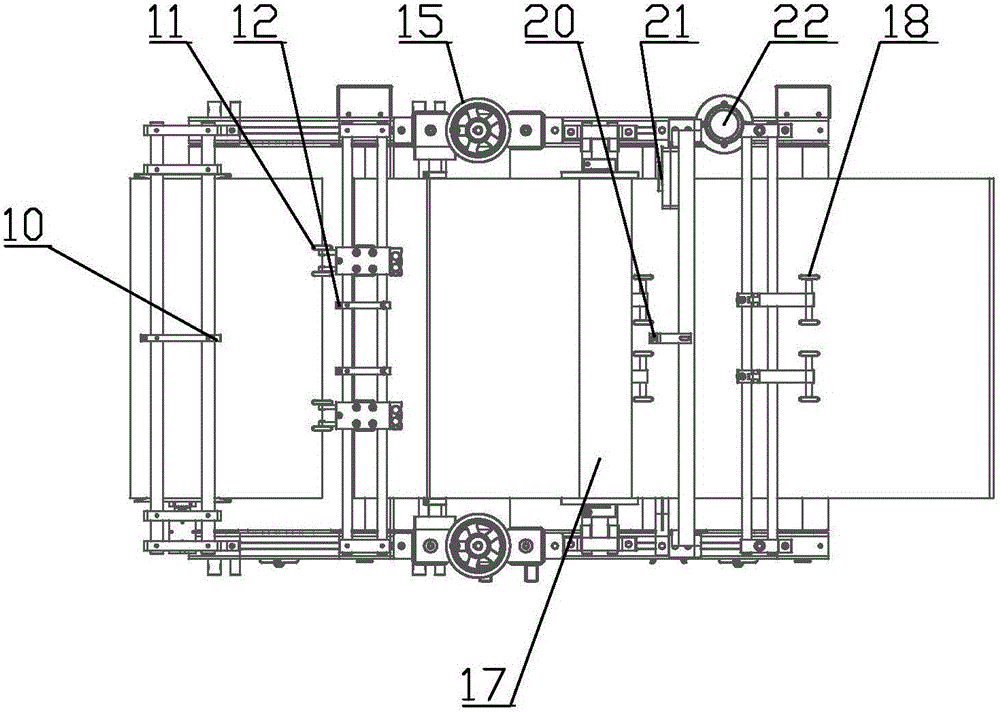

[0026] according to figure 1 , figure 2 and image 3 , the present invention provides a thin plate laminating machine, including casters 1, chassis 2, door panel 3, emergency stop switch 4, touch screen 5, handle 6, rear conveying unit 7, front conveying unit 8, guide mechanism 9, feeding Sensor 10, pinch wheel 11, sensor 12, stopper mechanism 13, film roll 14, hand wheel 15, lamination rubber roll 16, discharge roller 17, automatic pinch wheel 18, rodless cylinder 19, cutting sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com