Telescopic spraying teaching mechanism with hemispherical operation range

A technology with a working range and a hemisphere, applied in the field of teaching equipment, can solve the problems of complex and changeable spraying workpieces, and achieve the effect of flexible manual operation of the spray gun, easy to popularize and use, and lightweight manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

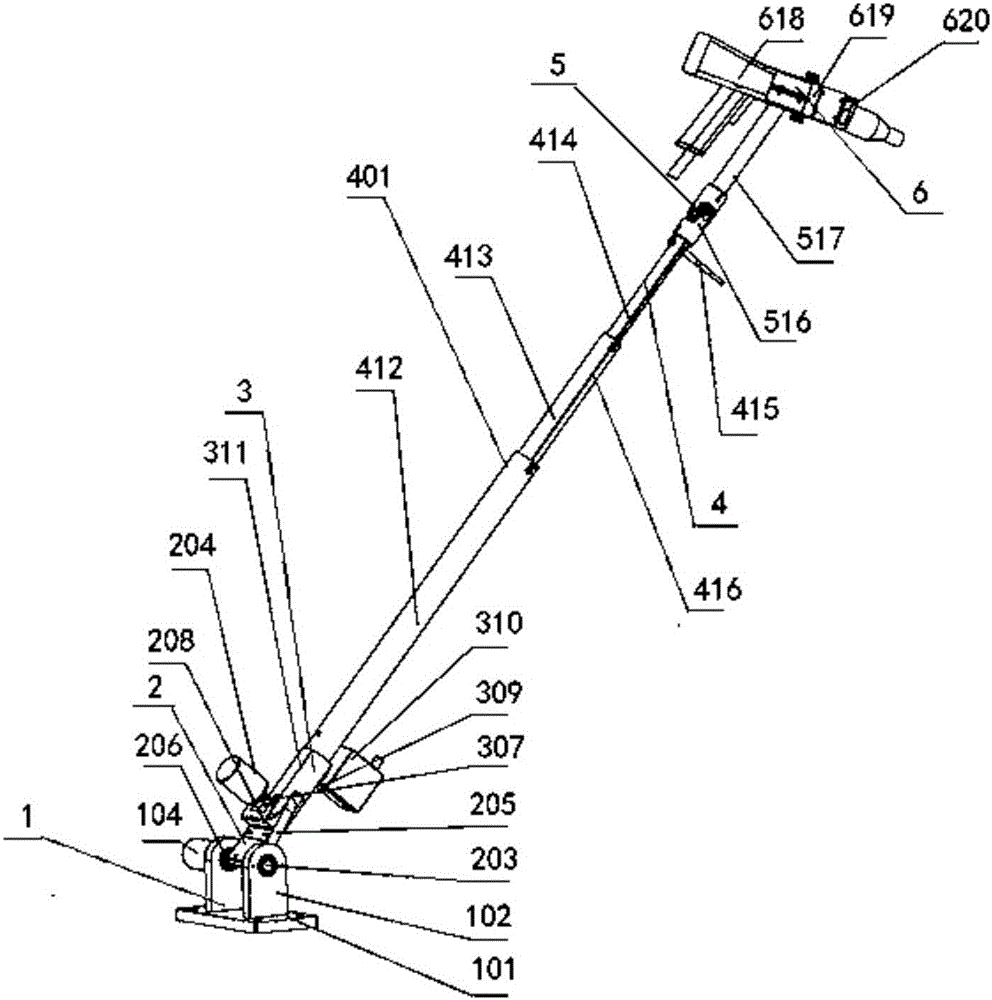

[0026] figure 1 As shown, a telescopic spraying teaching mechanism with a hemispherical working range includes a base 1, a rotating shaft plate 2, a connecting device 3, a telescoping device 4, a teaching wrist mechanism 5, and a spray gun device 6. The base 1 Fixedly installed on the ground, the rotating shaft plate 2 and the base 1 are rotationally connected through the base rotating shaft 203, the connecting device 3 and the rotating shaft plate 2 are rotationally connected through the rotating shaft 307, and the base rotating shaft 203 and the rotating shaft 307 are combined in a cross manner , can realize the free rotation in the hemispherical surface of the teaching mechanism, the mechanism has a large operating range and no dead point, no i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com