A method for measuring wavelength indication error of ultraviolet-visible spectrophotometer

A spectrophotometer and display value error technology, which is applied in the measurement of color/spectral characteristics, analytical materials, instruments, etc., can solve the problems of inability to display value error measurement, and achieve the effect of significant economic and social benefits and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

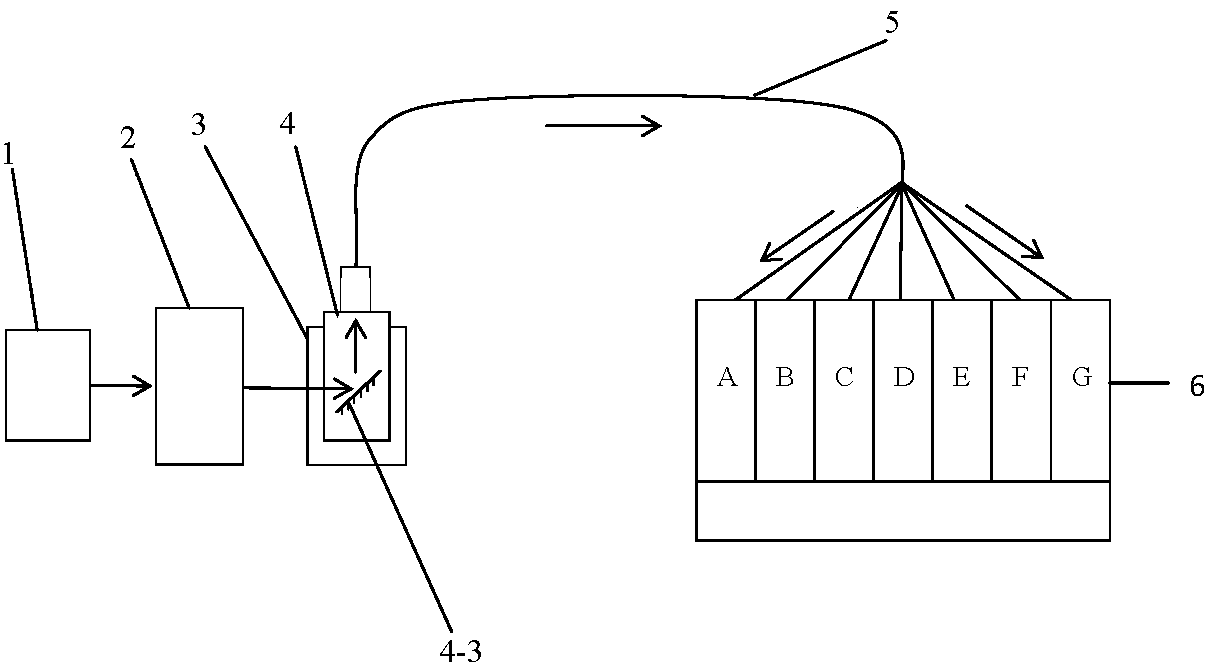

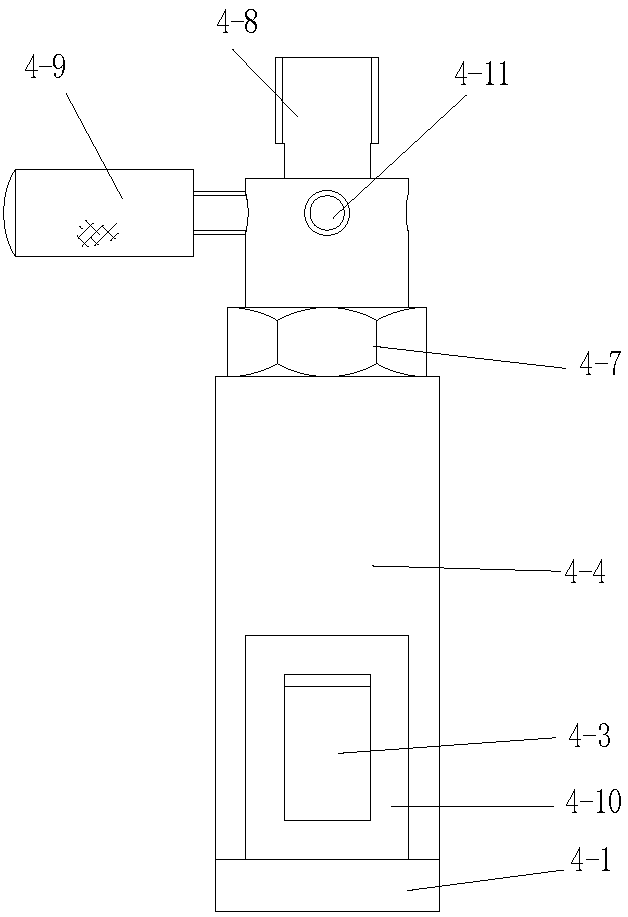

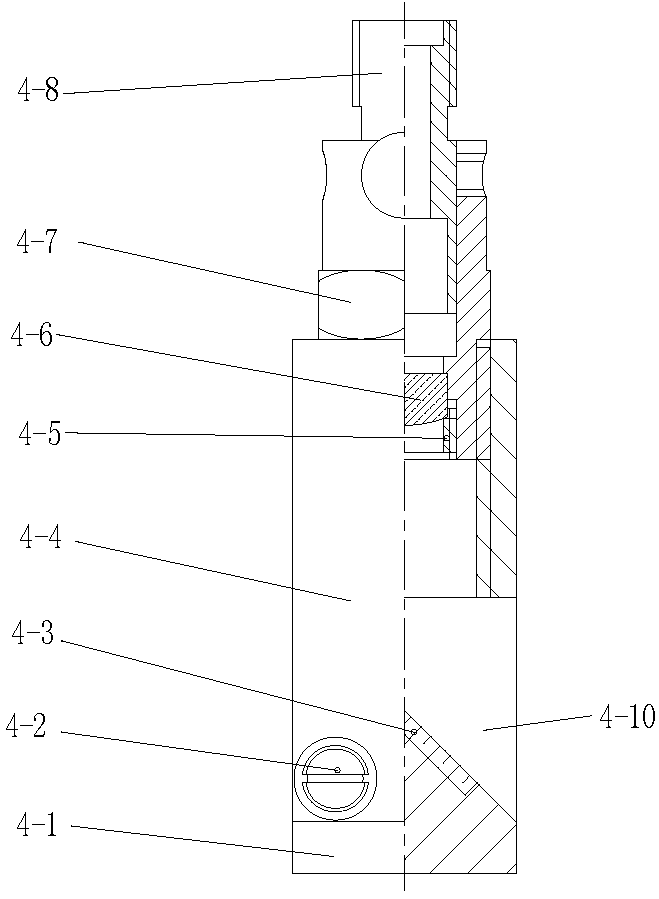

[0017] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings and specific conditions.

[0018] In concrete implementation, the present invention is realized by the following steps:

[0019] 1) Wavelength calibration of fiber optic spectrometer:

[0020] The fiber optic spectrometer uses the LIBS 2500 plus fiber optic spectrometer produced by Ocean Optics. The fiber optic spectrometer adopts 7-channel parallel connection mode, the wavelength range is 200-900 nm, and the minimum wavelength resolution is 0.01 nm; Hg lamp, Xe lamp, and Ar lamp are respectively used , The Ne lamp is used as a standard light source, and an average of 1 wavelength point is calibrated every 8-12nm, and the wavelength of the fiber optic spectrometer is calibrated to ensure that the wavelength value of the fiber optic spectrometer is effectively restored;

[0021] 2) Install measuring equipment:

[0022] The measuring equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com