Digital type tear strength tester

A technology of tear strength and tester, which is applied to strength characteristics, instruments, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of cumbersome operation, low test accuracy, and large test error, and achieve small test error , Improve test efficiency, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

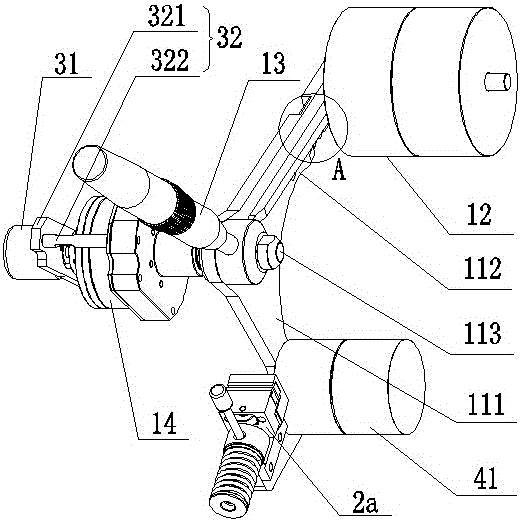

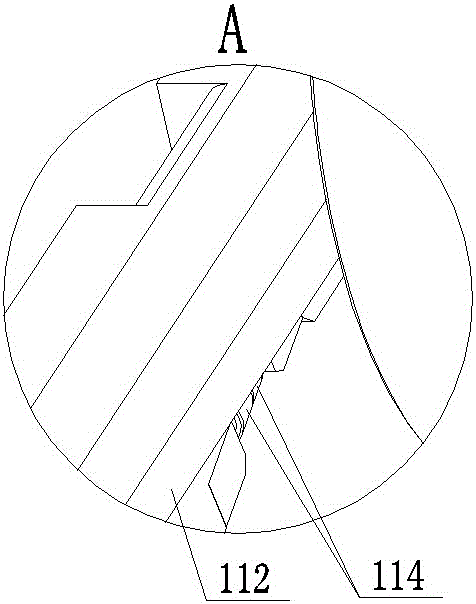

[0035] The present invention adopts a pendulum structure, uses the principle of pendulum gravitational potential energy and kinetic energy conversion, to tear the sample fixed on the clamping device, and then calculates the tear resistance of the sample through the loss of energy. The present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

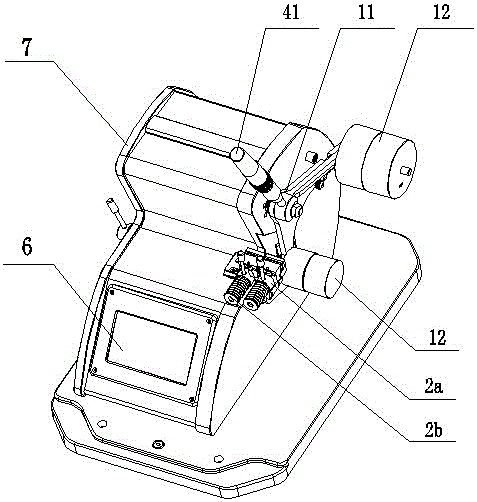

[0036] Such as Figure 1 to Figure 7 As shown, the present invention discloses a digital tear strength tester, which includes an energy conversion mechanism for converting gravitational potential energy into kinetic energy, a clamping mechanism for clamping test samples, a measuring mechanism for measuring energy loss and Master control unit for calculating measurement data. The movable part 2a of the clamping mechanism is connected with the energy conversion mechanism, and the fixed part 2b of the clamping mechanism is installed on the frame 7 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com