Range-extending electric hybrid generator and engine crankshaft connecting device

A coupling device and generator technology, applied in the direction of machines/engines, electromechanical devices, electric components, etc., can solve problems such as belt slippage, accelerated bearing wear, and crankshaft power output shaft fracture, etc., to achieve a reasonable and stable overall structure design The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

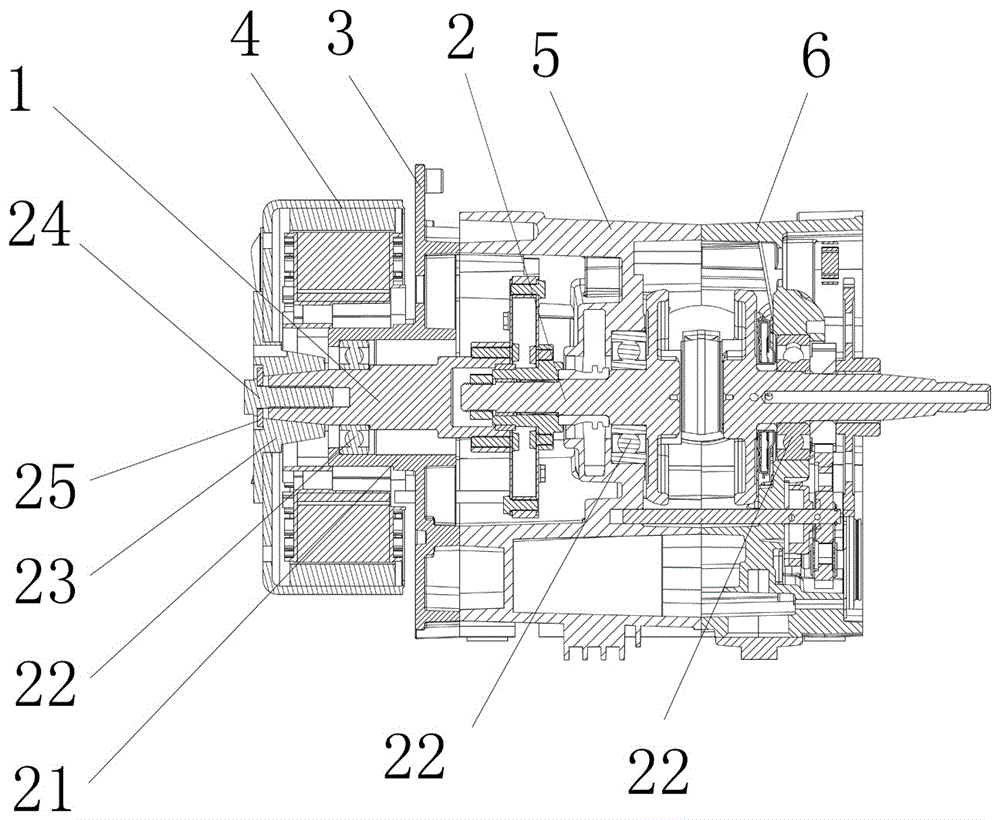

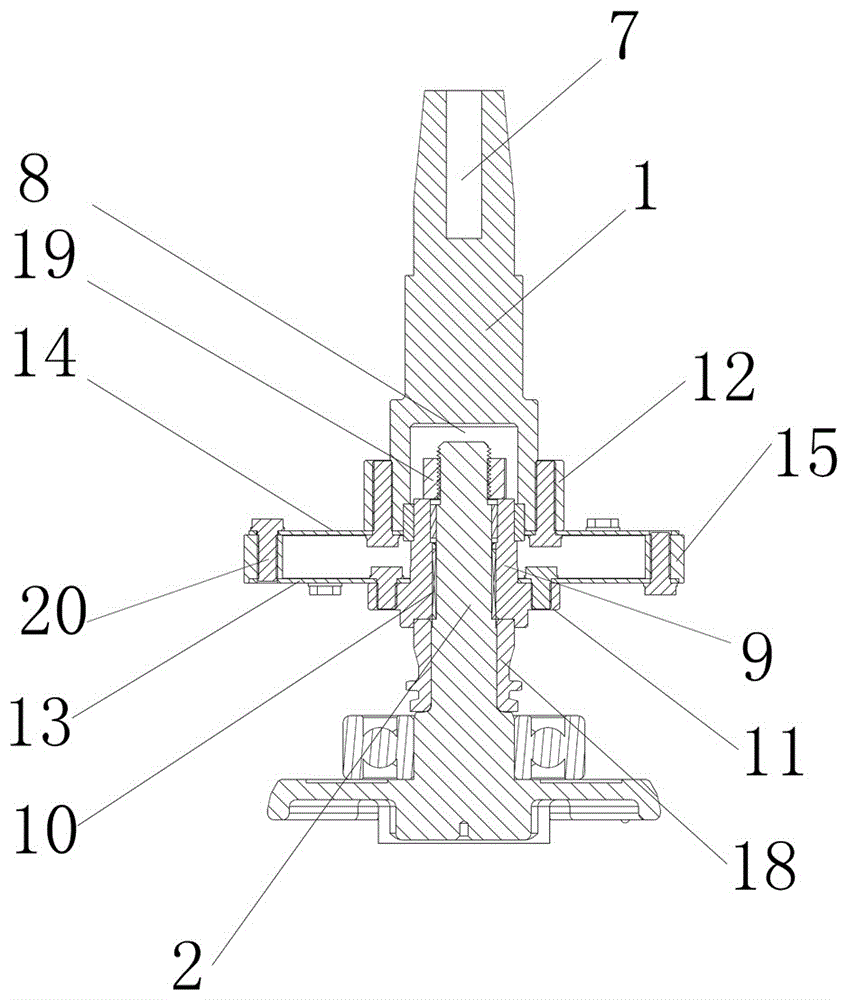

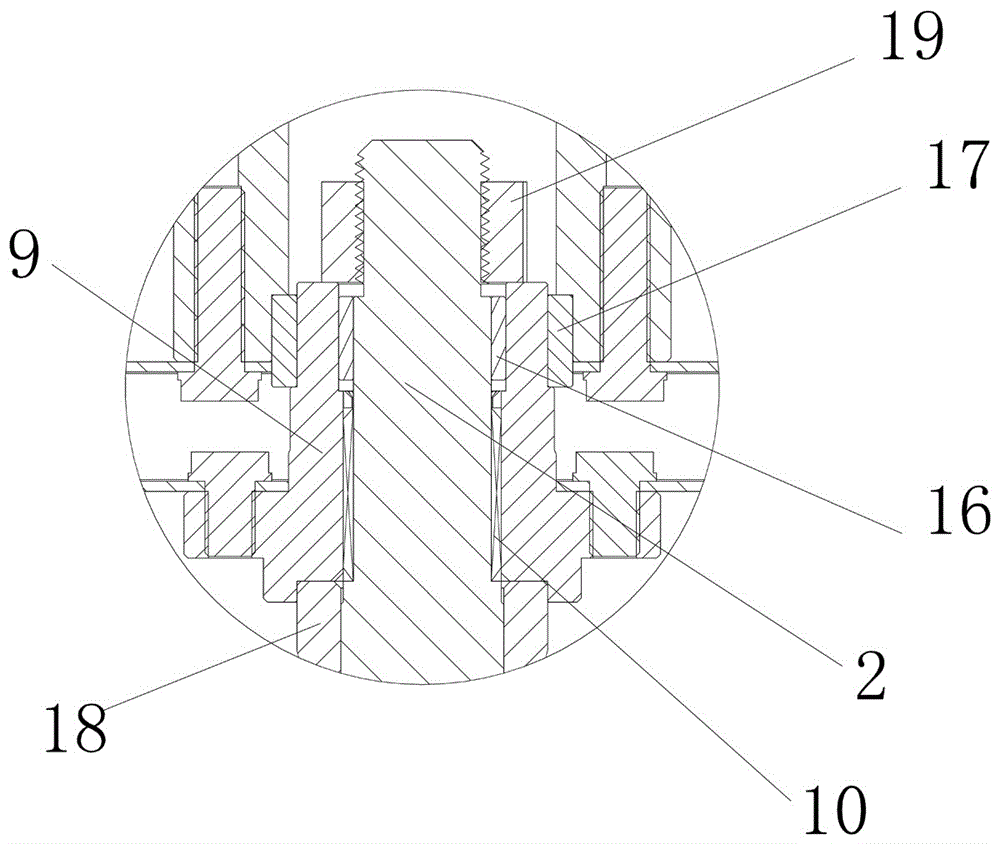

[0023] see Figure 1-Figure 3 , a coupling device between an extended-range electric hybrid generator and an engine crankshaft, comprising a generator shaft 1, an engine crankshaft 2, a generator connecting plate 3 and a generator rotor 4 corresponding to the generator shaft 1, and a generator rotor 4 corresponding to the engine crankshaft 2 The left box body 5 and the right box body 6 are set, and the left box body 5, the right box body 6 and the generator connection plate 3 are fixedly connected, and the support sleeve 21 is arranged in the generator connection plate, and the support sleeve A locating bearing 22 is arranged between the pipe 21 and the generator shaft, and a locating bearing is also arranged between the left casing and the right casing and the crankshaft of the engine.

[0024] The upper part of the generator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com