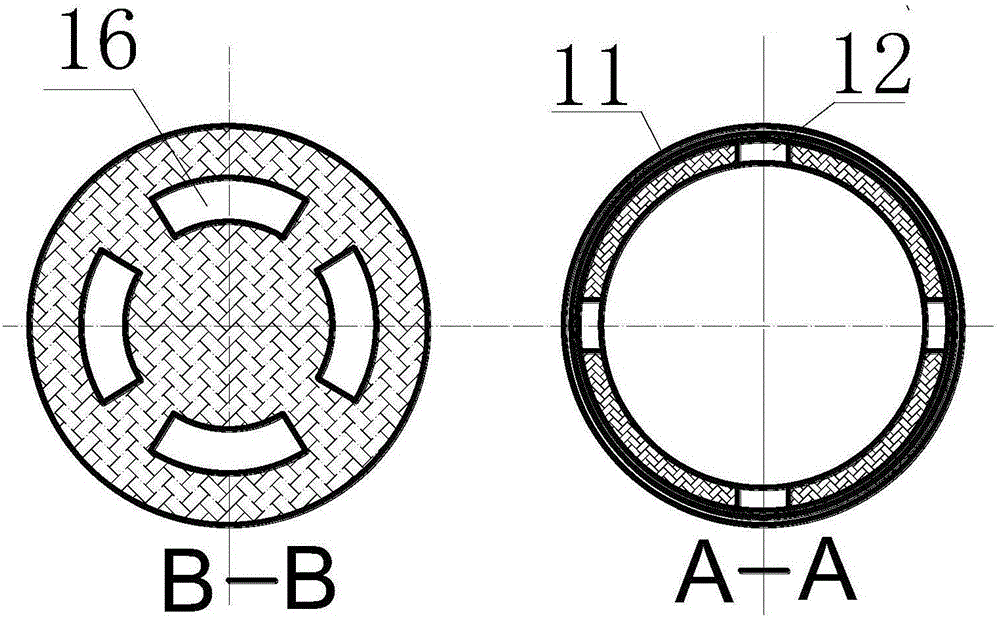

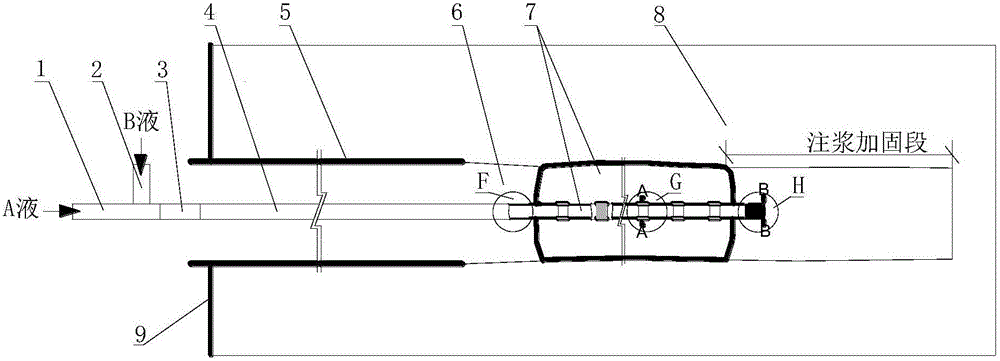

Separated grouting device in drilled hole and sectional grouting operation process

A technology of grouting device and operation process, which is applied in earth-moving drilling, infrastructure engineering, wellbore/well components, etc. Problems such as difficulty of grouting again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

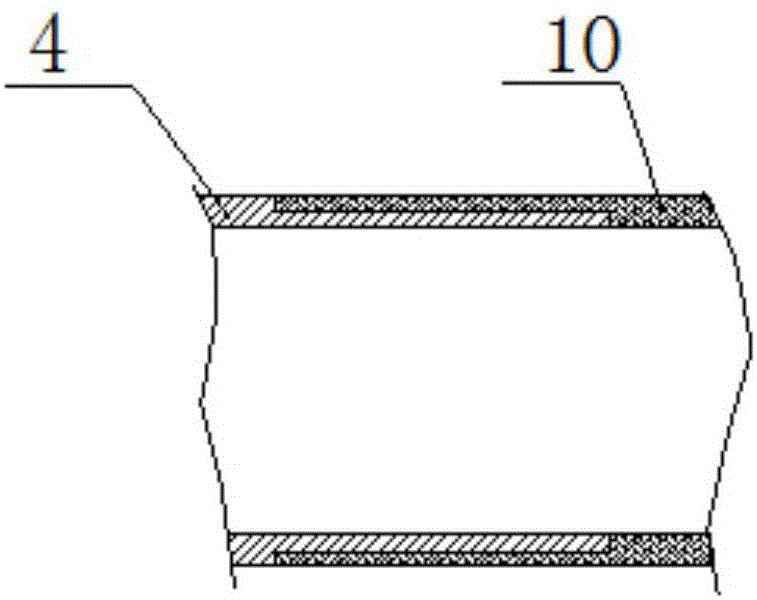

Method used

Image

Examples

Embodiment

[0064] Example: A highway tunnel in Cenxi City, Guangxi encountered a fully weathered granite stratum, which was rich in high-pressure water, and the stratum softened severely after being exposed to water. Water and mud inrush disasters were encountered many times during tunnel excavation, which seriously affected the progress of the project . In order to control the geological disaster of water and mud inrush, curtain grouting construction was carried out around the tunnel. Hole collapse and large water gushing often occur in curtain grouting drilling, which indicates that the surrounding rock of the drilling hole is loose and weak, it is difficult to drill holes, and the hole wall is irregular. The cost is high and the overall efficiency is poor. Moreover, the phenomenon of repeated grouting for shallower hole sections after grouting reinforcement also appeared. After the study, the separate grouting device in the borehole and the segmented grouting operation process of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com