Lifting machine

A technology of lifts and lifting frames, applied in the field of lifts, can solve the problems of unfavorable amino acid maintenance and monitoring, increase the workload of maintenance personnel, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

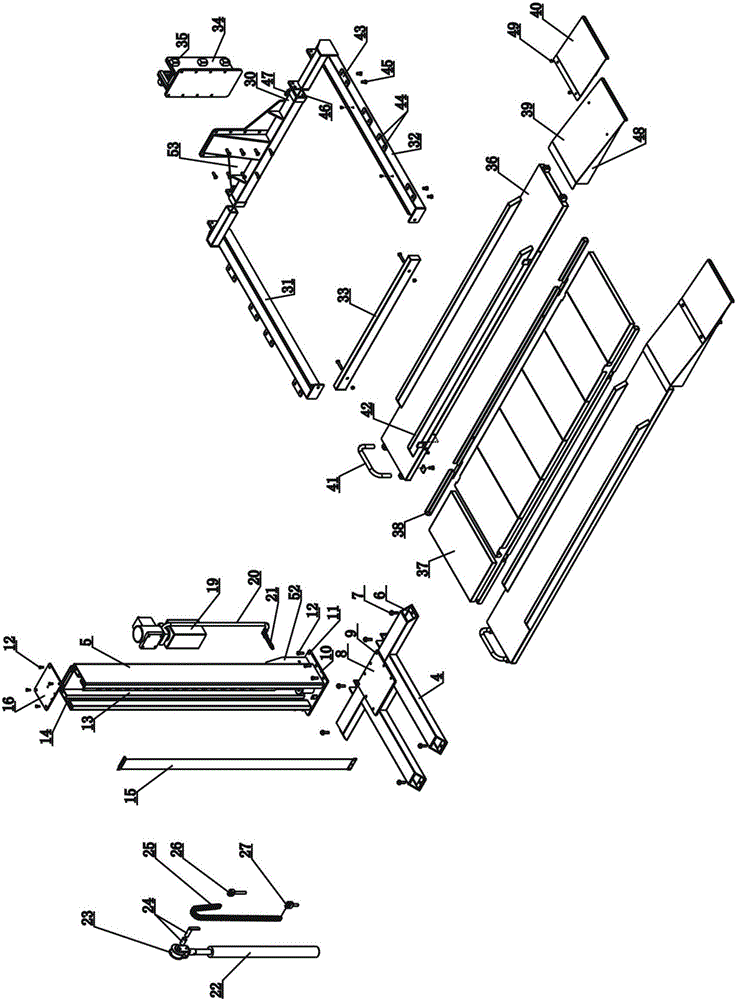

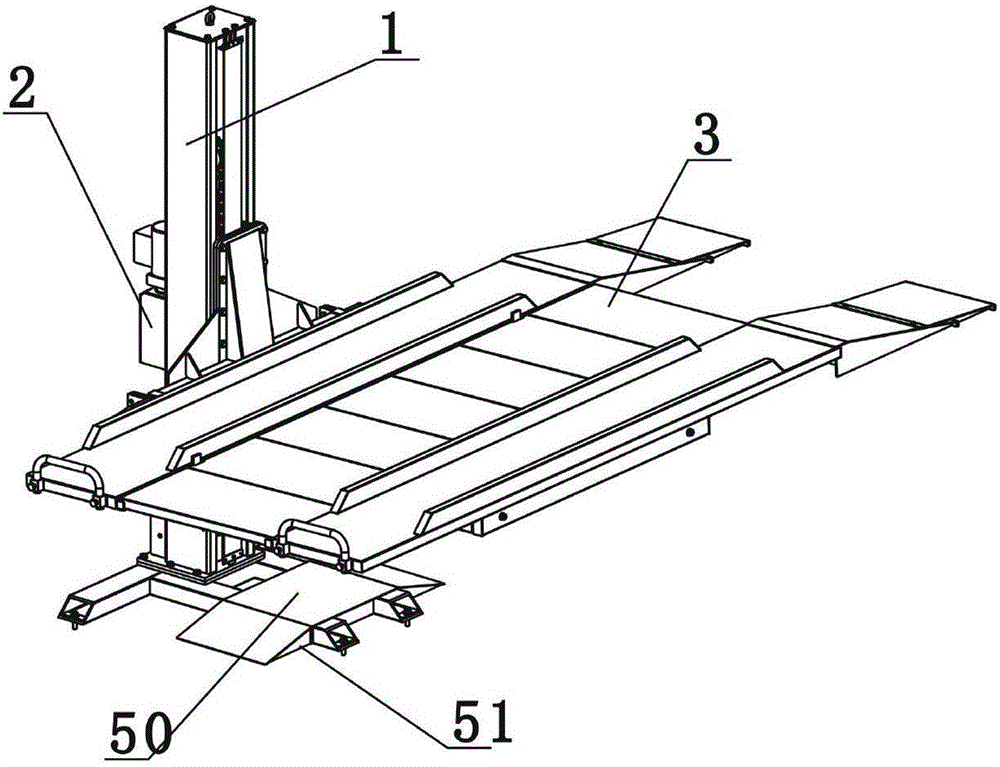

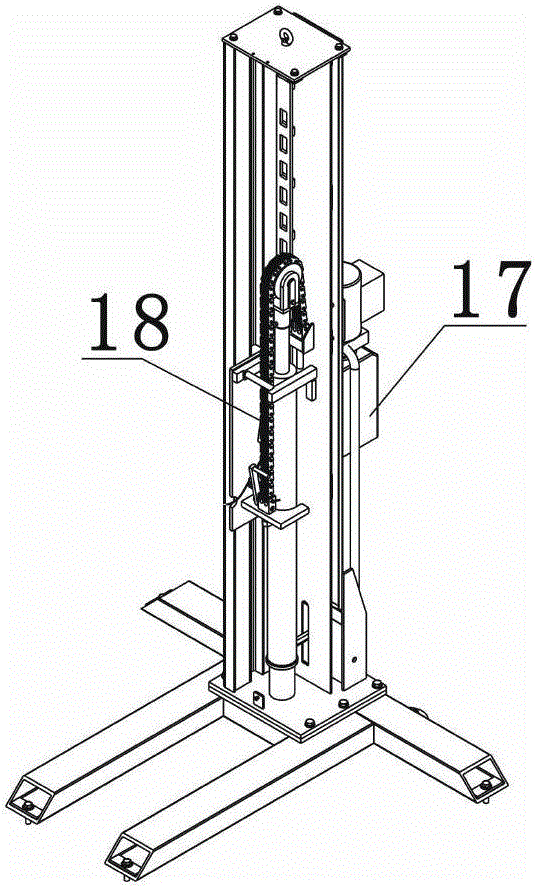

[0026] As an embodiment of the lift described in the present invention, as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a frame body 1, a hydraulic system 2 and a lifting system 3, the frame body 1 includes a chassis 4 and a column 5, the hydraulic system 2 is arranged on the column 5, and the lifting system 3 Connected to the hydraulic system 2; the underframe 4 is provided with a number of first bolt holes 6, and is fixed on the ground by expansion bolts 7. The design here can effectively fix the lift , so as not to collapse, the underframe 4 is welded with a first connecting plate 8, the first connecting plate 8 is provided with a number of second bolt holes 9, and the bottom of the column 5 is welded with a second connecting plate 10. The second connecting plate 10 is provided with a number of third bolt holes 11, the colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com