Connecting rod clamping mechanism and injection molding machine comprising same

A connecting rod locking and mold locking technology, which is applied in the field of injection molding machinery, can solve the problems of inconvenient maintenance, fire, and large wear of the five-point connecting rod, and achieve the effects of simple and convenient maintenance, increasing the contact surface, and compensating for mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

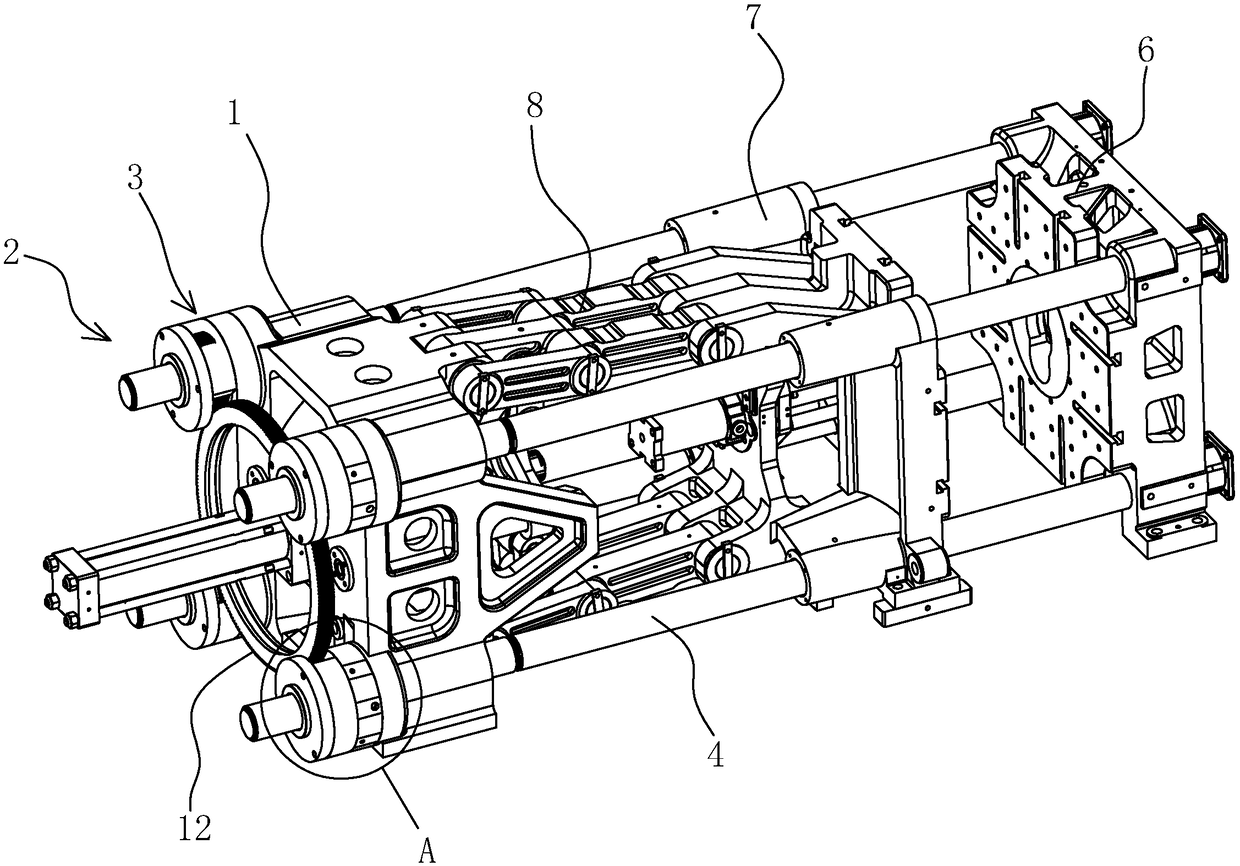

[0036] Specifically, the driving member 11 can be an oil cylinder or a roller screw. The oil cylinder is suitable for providing small torque, while the roller screw is suitable for providing high torque. In this embodiment, a five-point linkage mechanism is adopted. After the driving member 11 is connected with the formwork hinge assembly 8, it is used to expand the five-point linkage mechanism and drive the movable formwork 7 to the mold closing position to achieve a self-locking state.

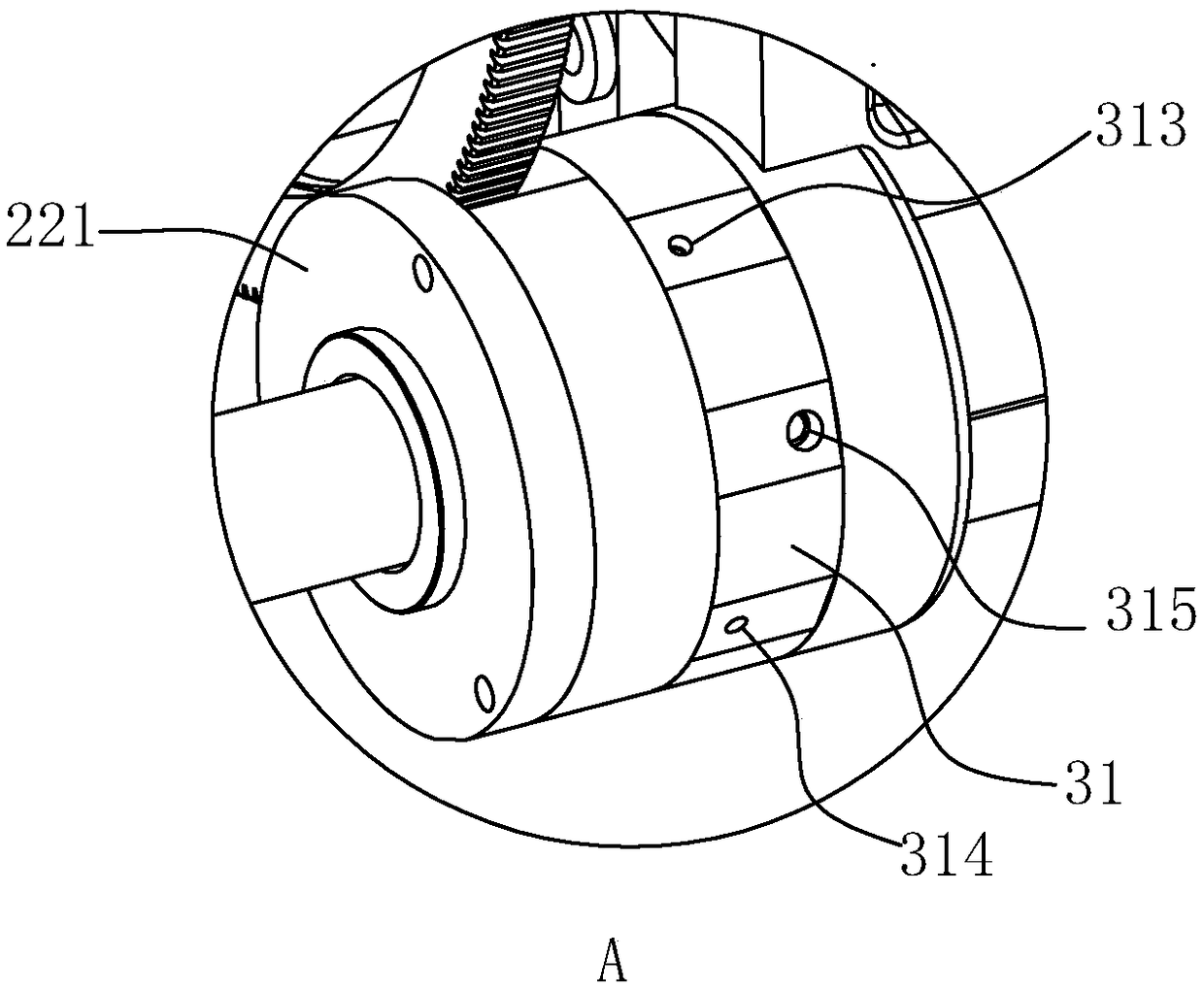

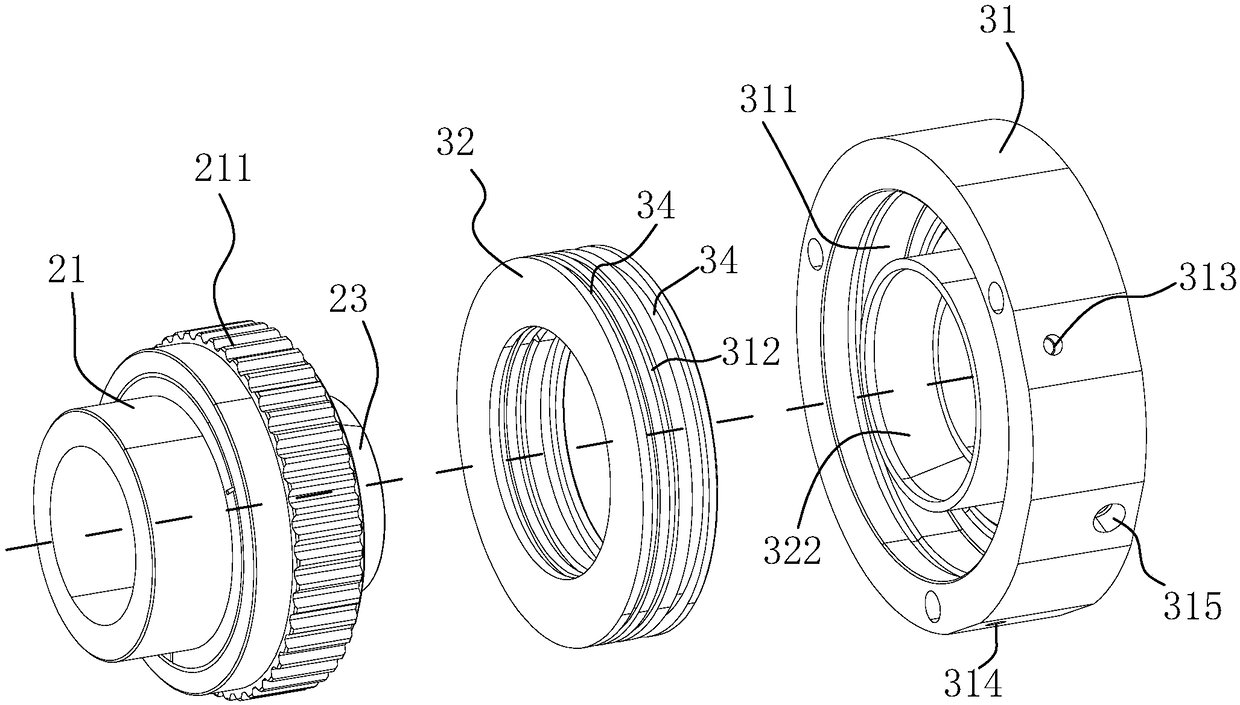

[0037] combined with figure 2 and 3 The mold clamping cylinder assembly 3 includes an oil cylinder body 31 extending outside the base plate 1. The oil cylinder body 31 is located at the position where the outer mold clamping tie rod 4 of the base plate 1 passes through. The oil cylinder body 31 is fixed to the base plate 1 in this embodiment. The connection, of course, can also be integrally formed with the substrate 1 as another implementation manner of this embodiment. The shape of the ...

Embodiment 2

[0047] Refer to the attached Figure 7 , On the basis of the first embodiment, the difference from the first embodiment is that the radial cross-sections of the piston 32 and the cylinder block 31 are both stepped, so that the stepped fingers are formed, and the piston 32 has a An extension of the inner wall, and the cylinder block 31 covers the outer circumferential surface of the piston 32 . An annular groove 34 is provided on the inner side wall of the oil cylinder block 31 and the outer side wall of the piston 32 , and a sealing ring is installed in the annular groove 34 . In this embodiment, the annular groove 34 may be provided with two places on the piston 32 and the oil cylinder block 31, and the two places can also be installed with a high-pressure sealing ring 35 and a low-pressure sealing ring 36 respectively. The modified structure can achieve a better sealing effect, and the leakage groove 312 can be omitted.

Embodiment 3

[0049] An injection molding machine, comprising the connecting rod clamping mechanism as in all the above-mentioned embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com