A device for automatically picking and placing push plates

An automatic pick-and-place and push plate technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that cannot meet the high-speed automatic production process, time-consuming, labor-intensive, etc., achieve high-speed automatic production process, not easy to damage , the effect of avoiding production loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

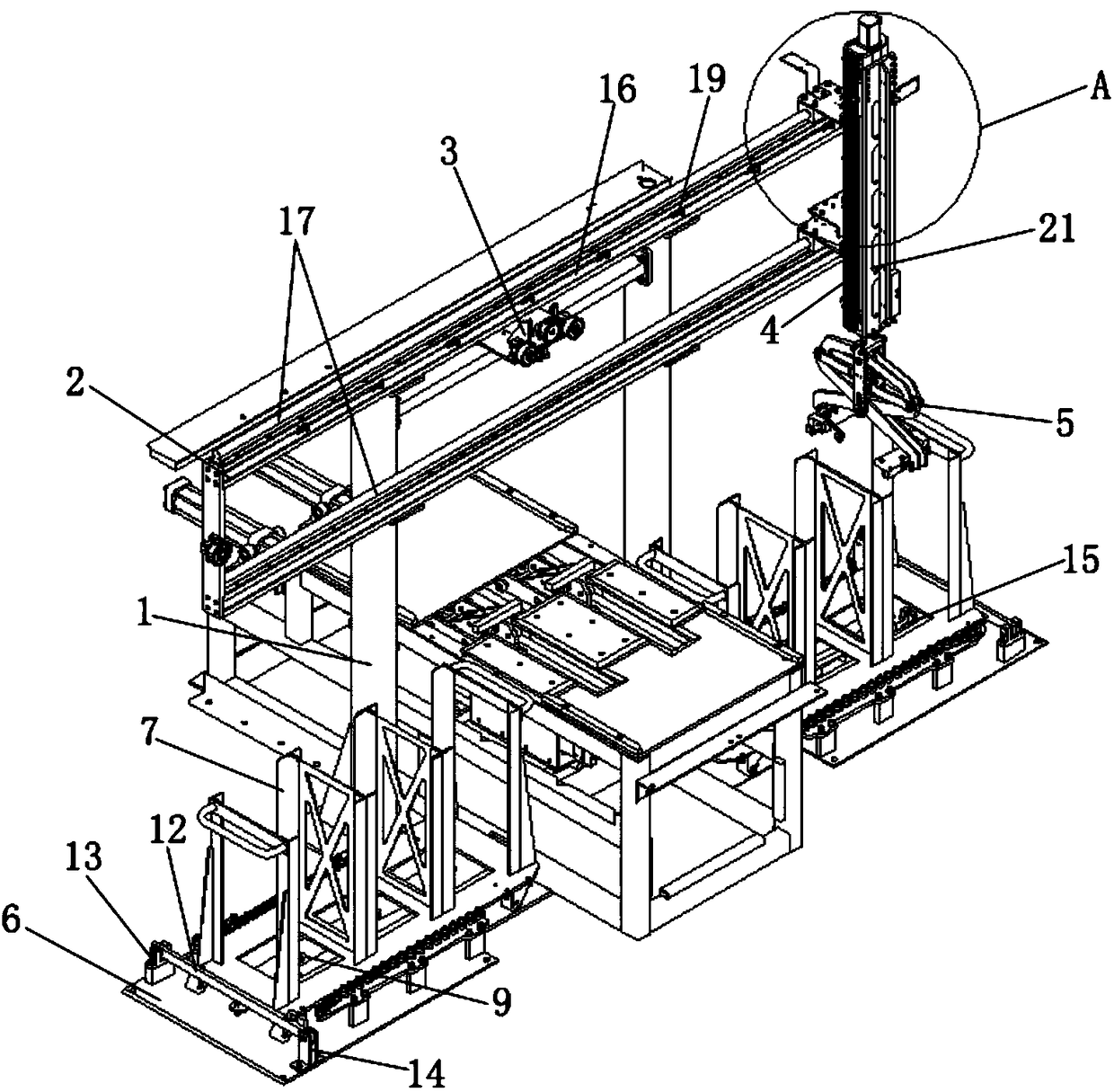

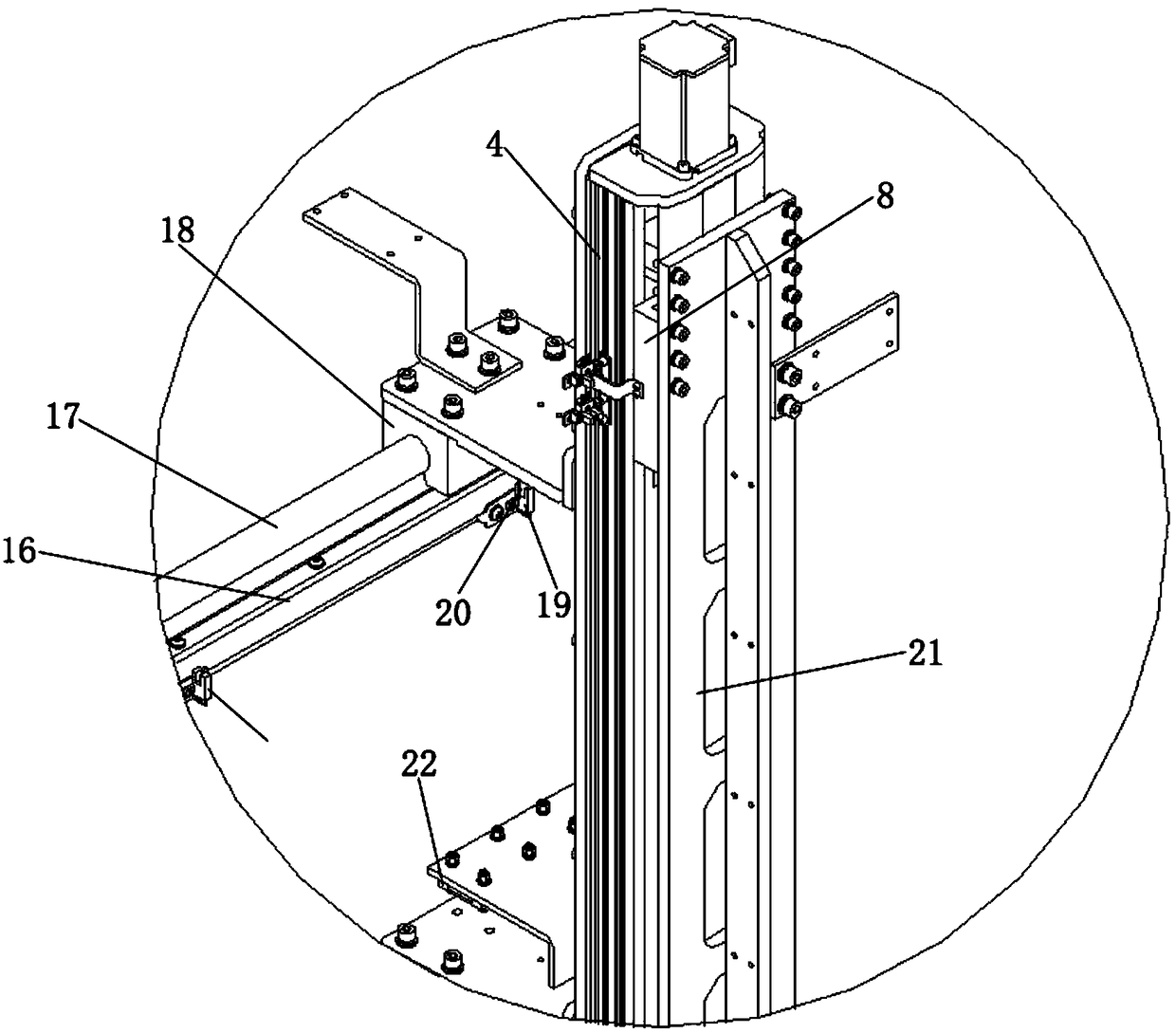

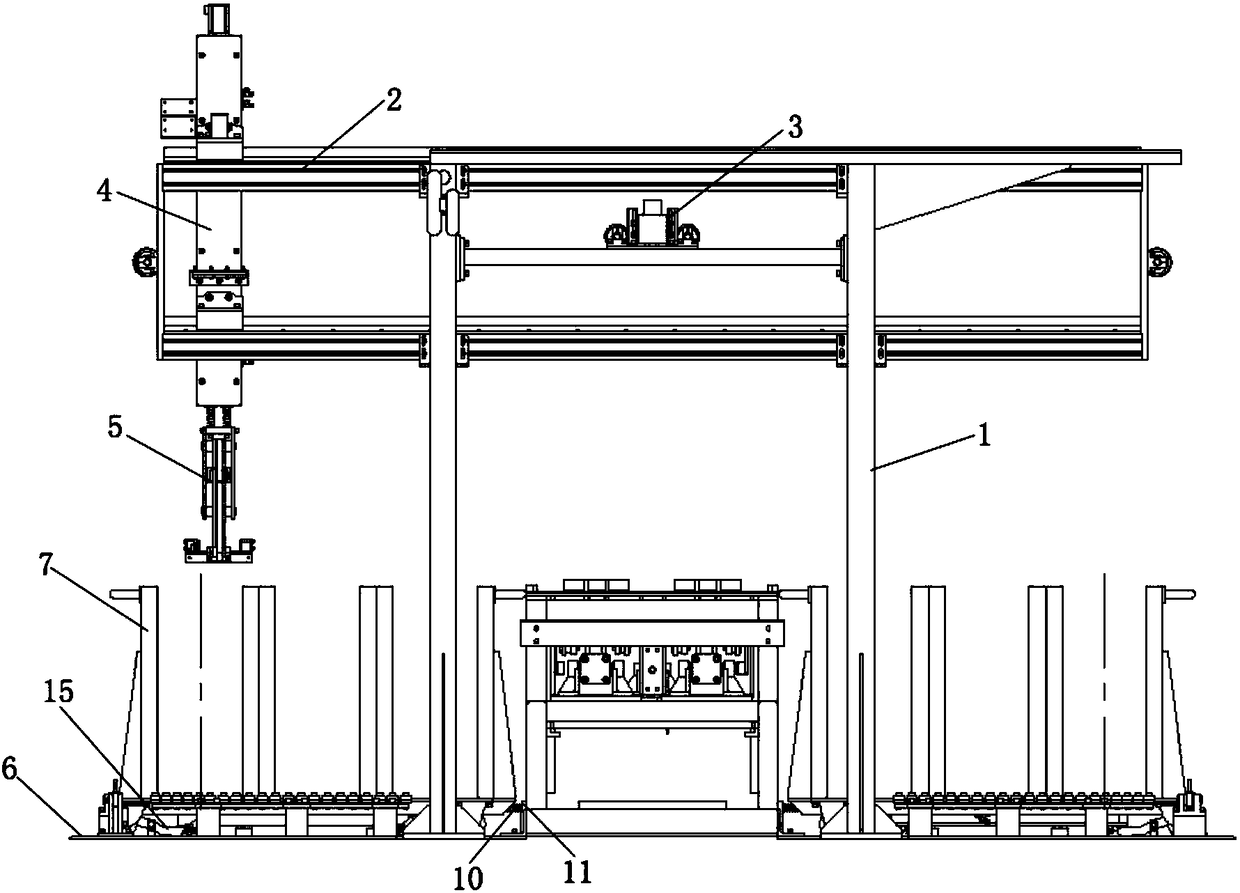

[0026] Such as Figure 1 to Figure 6 The device shown in the present invention is an automatic pick-and-place push plate, which is equipped on the push plate kiln production line, and realizes automatic plate supply through the combination of electrical and mechanical transmission. The device includes a main frame body 1, a transverse guide rail mechanism 2, a belt transmission mechanism 3, a linear guide rail module 4, a mechanical claw 5, a positioning frame 6 and a storage trolley 7. The main frame body 1 is the main supporting frame of the device, and as shown in the figure, the main frame body 1 is erected on the return board line of the pusher kiln. The upper part of the main frame body 1 is equipped with a horizontal guide rail mechanism 2 and a belt transmission mechanism 3. The linear guide rail module 4 is driven by the belt transmission mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com