Vehicle posture adjustment method for vehicles equipped with oil-pneumatic springs with locking function

An oil-pneumatic spring and an adjustment method technology, which is applied in the field of vehicle attitude adjustment and vehicle attitude adjustment, and can solve problems such as different extensions of spring piston rods, uneven vehicle heights, and mismatches in the normal distribution of spring oil filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0030] The vehicle attitude adjustment method for the vehicle equipped with the oil-gas spring with locking function provided in this embodiment combines the open loop control and the closed loop control process. In principle, the adjustment process is briefly described as follows:

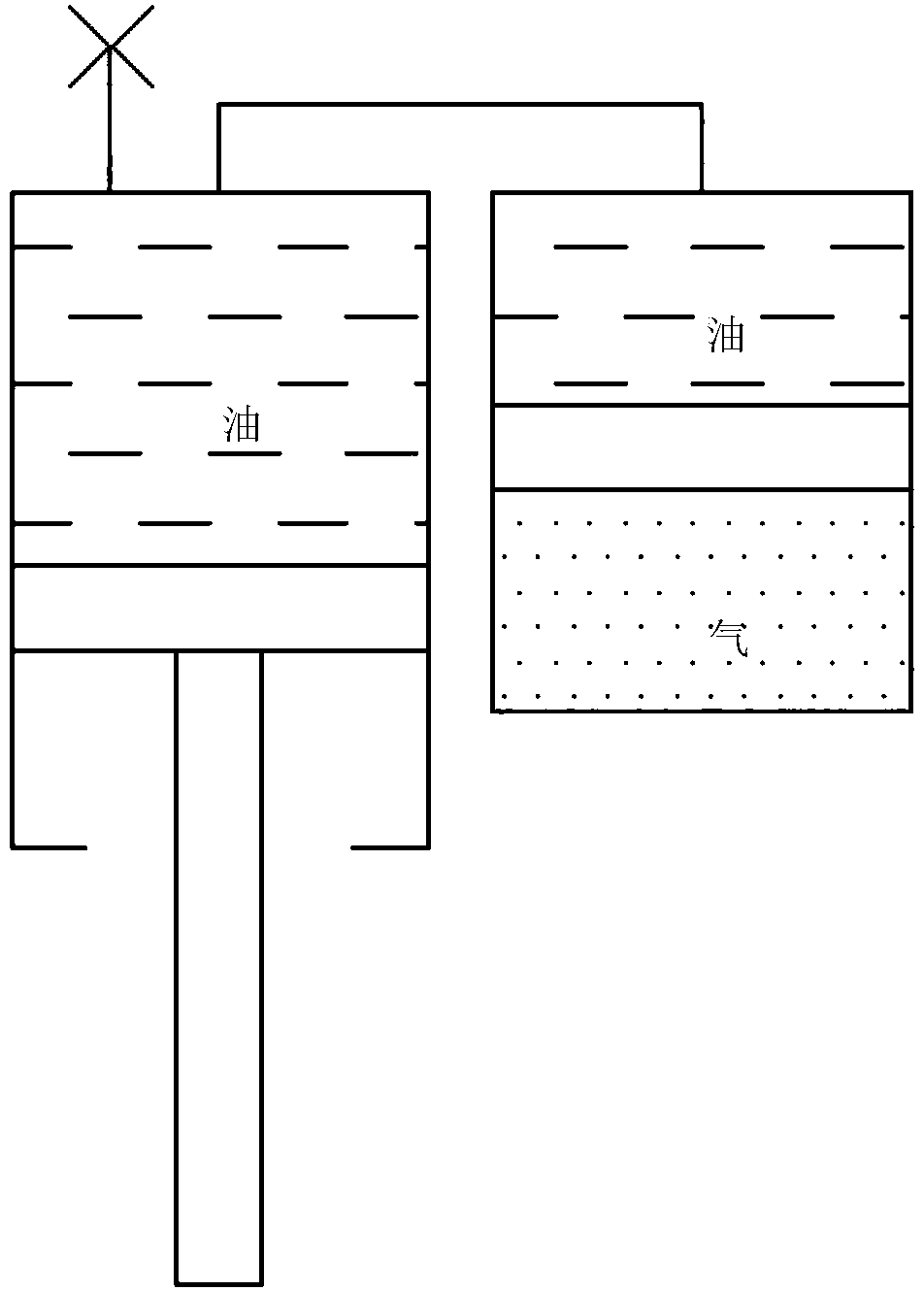

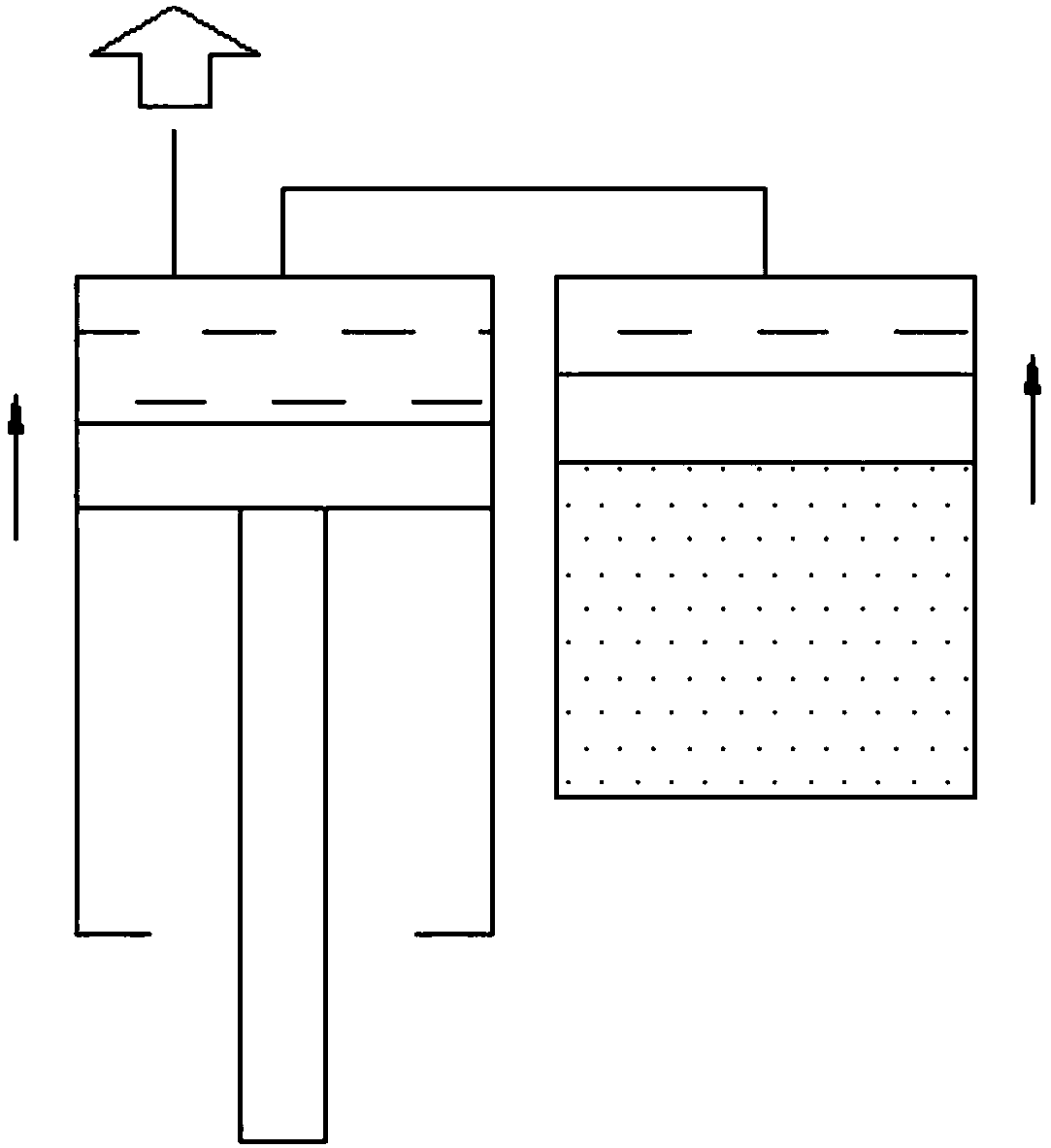

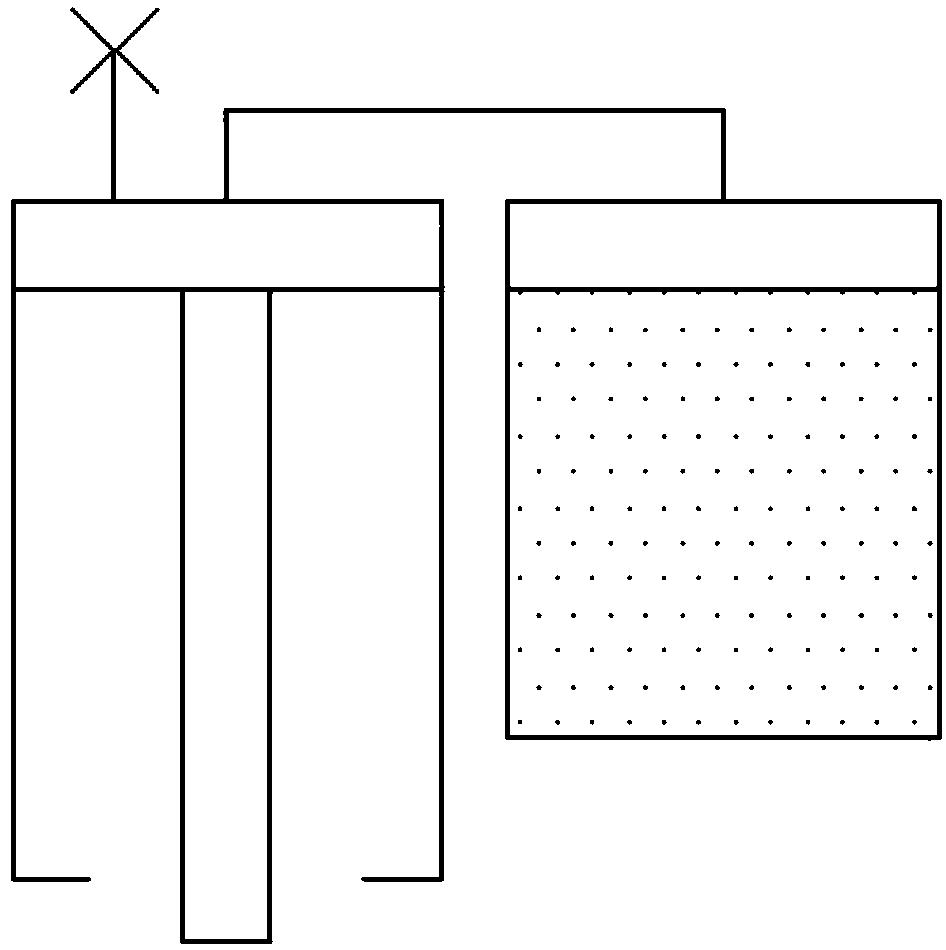

[0031] 1. Reference Figure 1 to Figure 6 As shown, through open loop control, the gas compression of the oil-gas spring can meet the requirements of vehicle load distribution;

[0032] 2. Reference Figure 7 with Figure 8 As shown, under the condition that the amount of gas compression remains unchanged, that is, when the oil-gas spring is locked, the oil-gas spring is filled or discharged under the closed loop of the sensor to adjust the vehicle height to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com