Density measuring device

A technology for density measurement, measuring equipment, used in the field of fluids flowing in pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

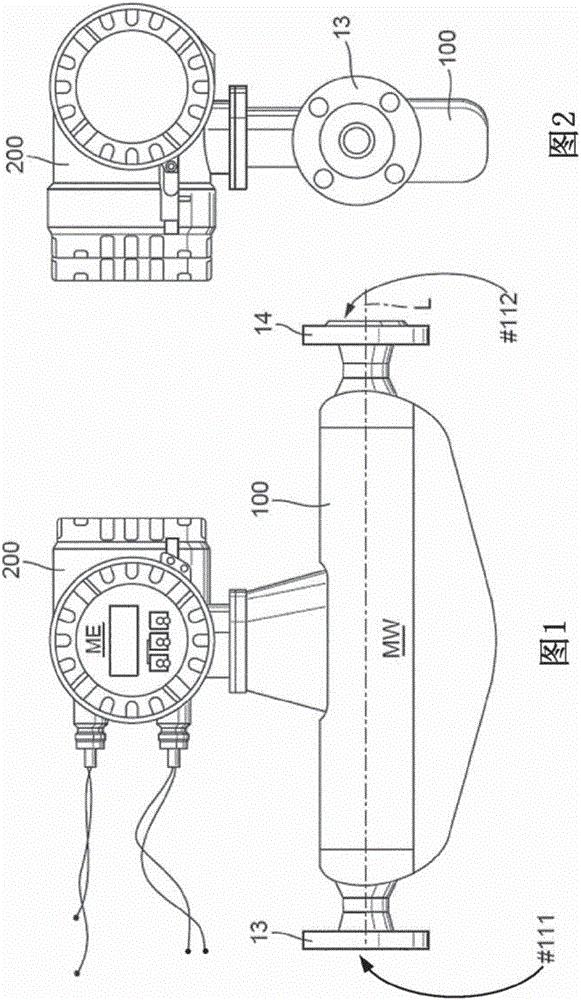

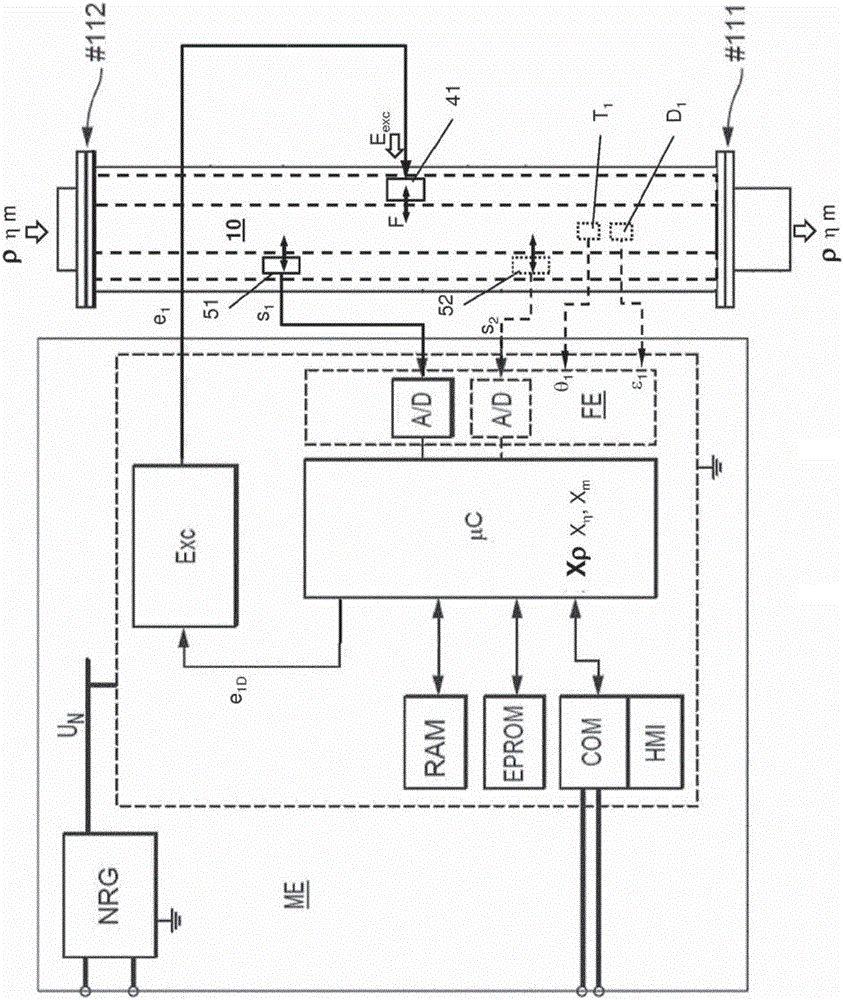

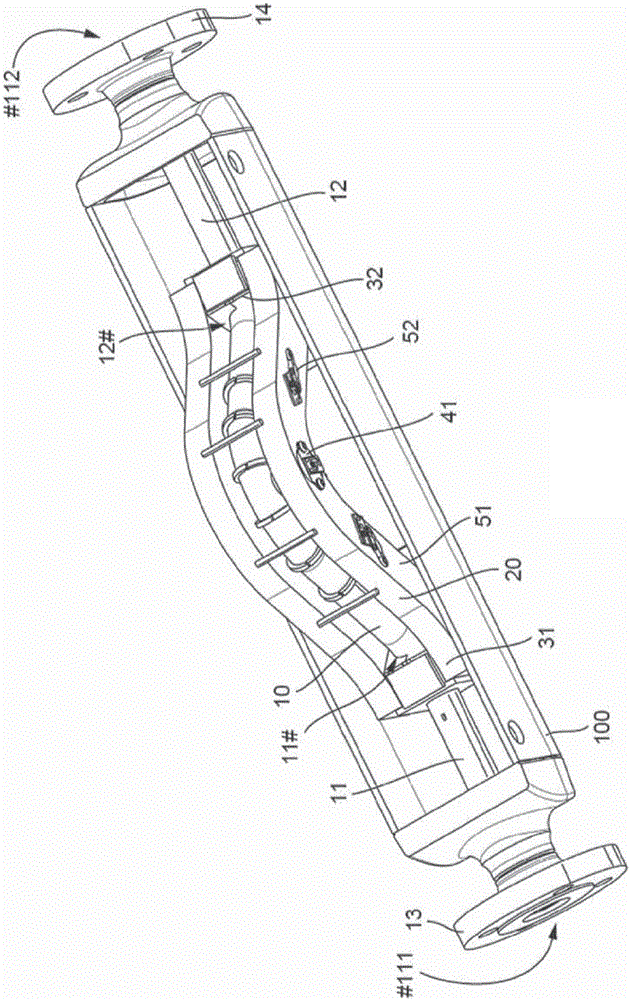

[0049] figure 1 with figure 2 A density measuring device is schematically shown in different side views for measuring the density of a medium, in particular a liquid or a gas, flowing in a process line (not shown) or for repeatedly determining the instantaneously expressed density The measured value (X ρ ). In a further embodiment of the invention, the density measuring device is furthermore configured to additionally also measure the viscosity of the medium or to determine a corresponding measured value (X η ). As an alternative or in addition thereto, the density measuring device can also be adapted to determine the mass flow, i.e. the total mass and / or the mass flow flowing during a predeterminable or earlier determined measuring interval, for the medium flowing in the pipeline, or to determine Correspondingly represents the measured value of the mass flow rate (X m ).

[0050] The density measuring device comprises a vibratory measuring transducer MW via inlet port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com