Electromagnetically actuatable spring pressure brake and method for the production thereof

A spring pressure, brake technology, applied in the direction of brake type, automatic brake, brake components, etc., can solve the problems of large air gap, increase installation cost, and tolerance is not eliminated, and achieve the effect of small air gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

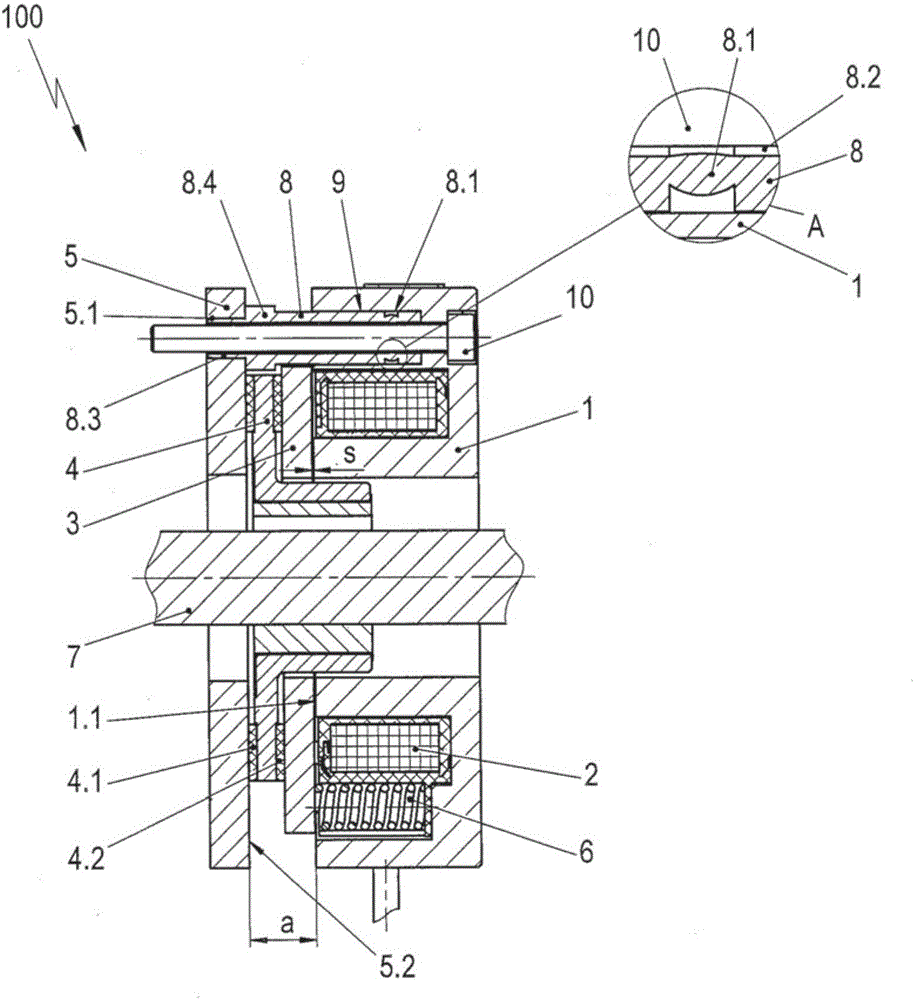

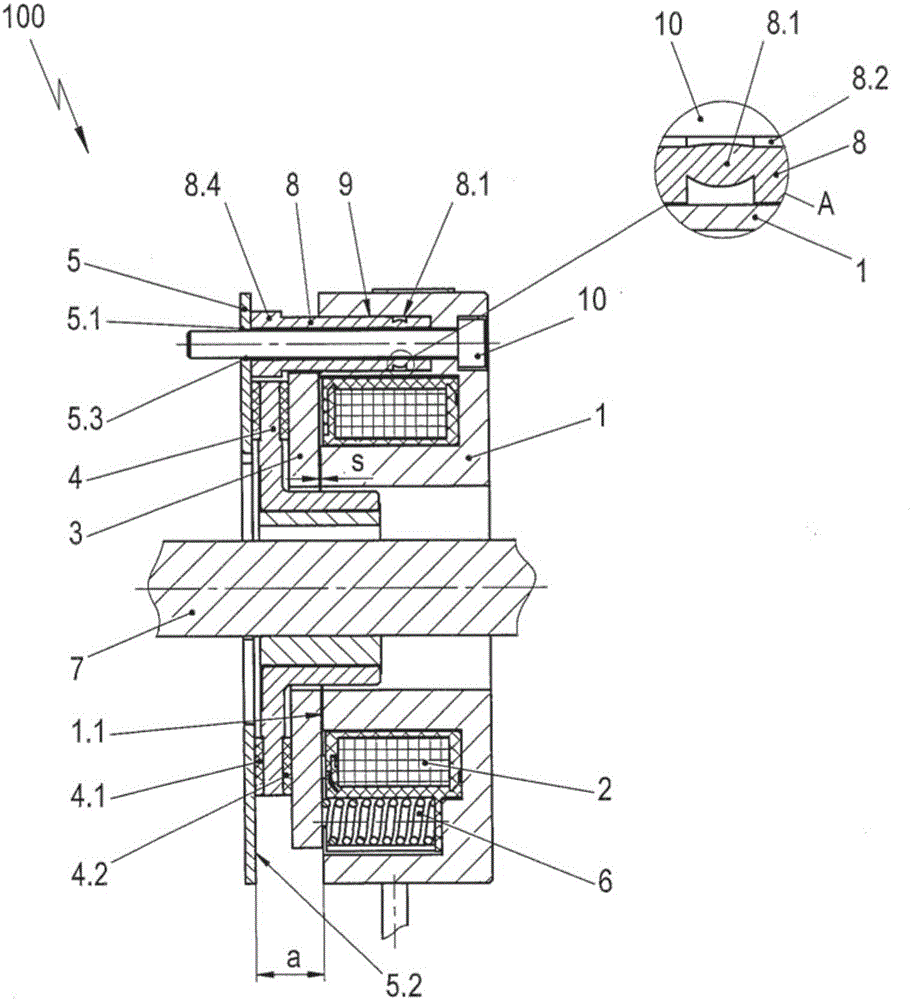

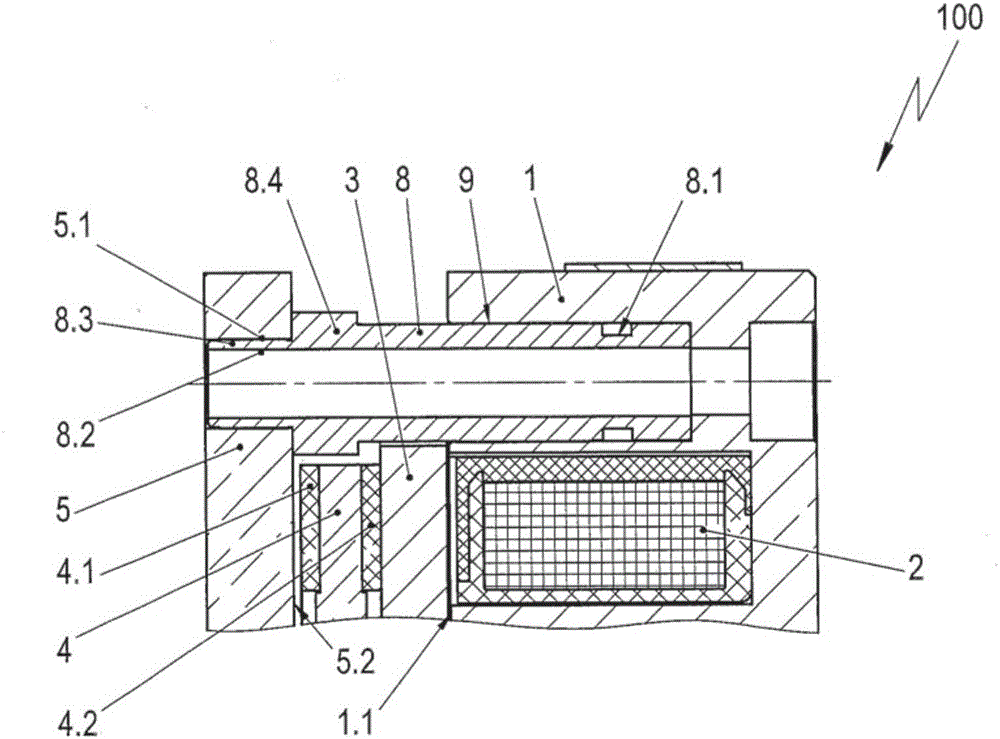

[0065] according to Figure 1-a The electromagnetically operable spring pressure brake 100 comprises a pot-shaped magnet as a magnet housing 1, the pot-shaped magnet has a for example annular coil 2 housed in the pot-shaped magnet 1, and the electromagnetically operable spring pressure brake 100 For example, it is arranged concentrically with respect to the shaft 7 to be braked, for example the motor shaft. Arranged in a rotationally fixed manner on the shaft 7 to be braked is a friction disk 4 which is situated between the armature 3 and the friction plate 5 as a friction element with a friction surface 5.2, the armature 3 being radially guided, However, it is axially displaceable and the friction plate 5 is connected to the magnet housing 1 by means of a plurality of screw-shaped connecting elements 8 . The friction surface 5 . 2 is located on the side of the friction plate 5 which is adjacent to the friction disk 4 . exist Figure 1-a Only a single screw-shaped connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com