Precision waterproof parts with ultra-thin circuit boards and molds and processes for forming the parts

A circuit board, ultra-thin technology, which is applied in precision waterproof parts and molds and processes for forming the parts, can solve the problems of inconvenient use, fixed installation of FPC circuit boards, etc., and achieve low surface tension, good product performance, and durability Good temperature and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

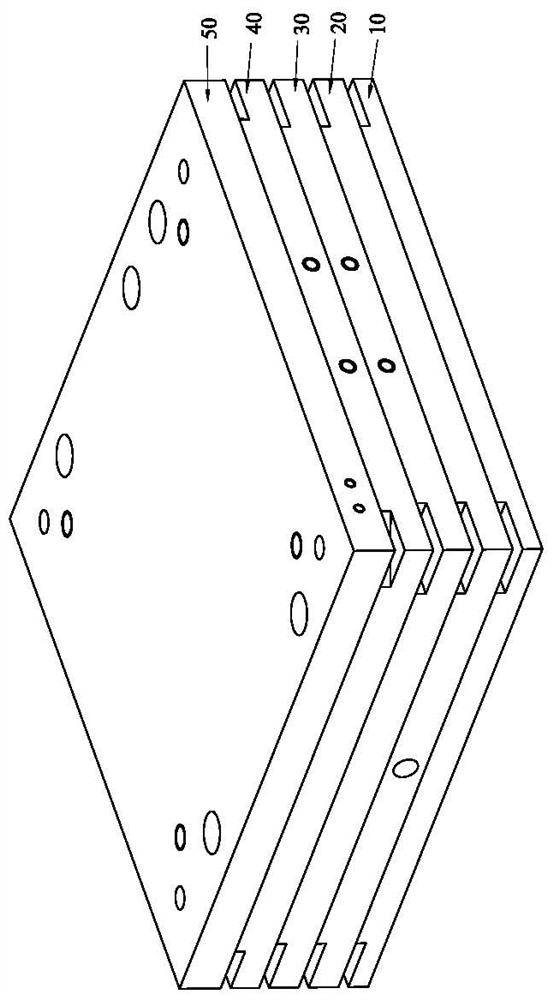

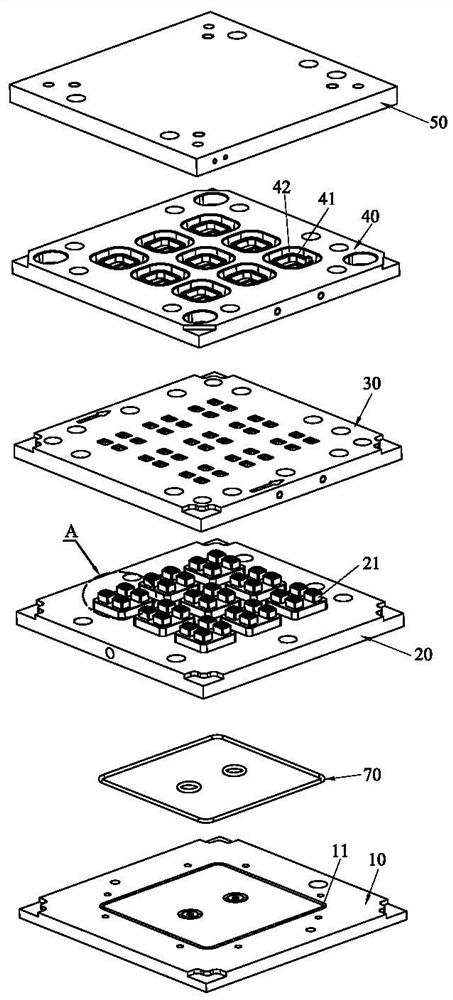

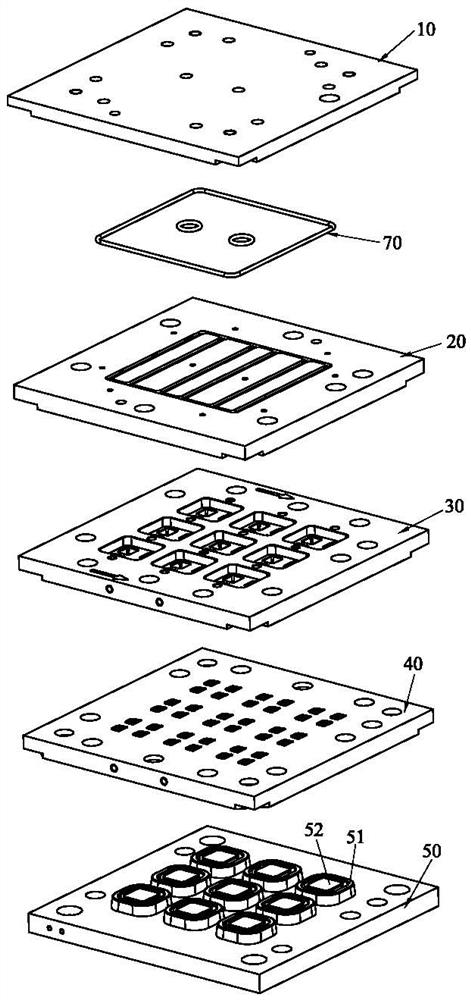

[0045] The invention discloses a mold for forming precision waterproof parts with ultra-thin circuit boards, such as Figure 1 to Figure 6 As shown, it includes an air chamber bottom cover 10, a core plate 20, a middle plate 30, an upper formwork 40 and a binder plate 50, the air chamber bottom cover 10, a core plate 20, a middle plate 30, an upper formwork 40 and The pressing plates 50 are stacked together sequentially from bottom to top.

[0046] A sealed air chamber 201 is formed between the bottom surface of the core plate 20 and the surface of the bottom cover 10 of the air chamber, and at least one core 21 is protruded from the surface of the core plate 20 , and the core 21 extends upward through the middle plate 30 To the bottom surface of the upper template 40, the end surface of the core 21 and the upper template 40 face form a cavity, and the end surface of the core 21 is concavely provided with a positioning cavity 202 for the FPC circuit board 61 and an annular gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com