Breaker with water tank

A technology for circuit breakers and water tanks, applied in circuits, parts of protection switches, electrical components, etc., can solve the problems of poor heat dissipation performance of circuit breakers, inability to achieve heat dissipation effects, and unreasonable structural settings, so as to reduce quality and accident hazards. , Reduce various quality and accident hazards, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

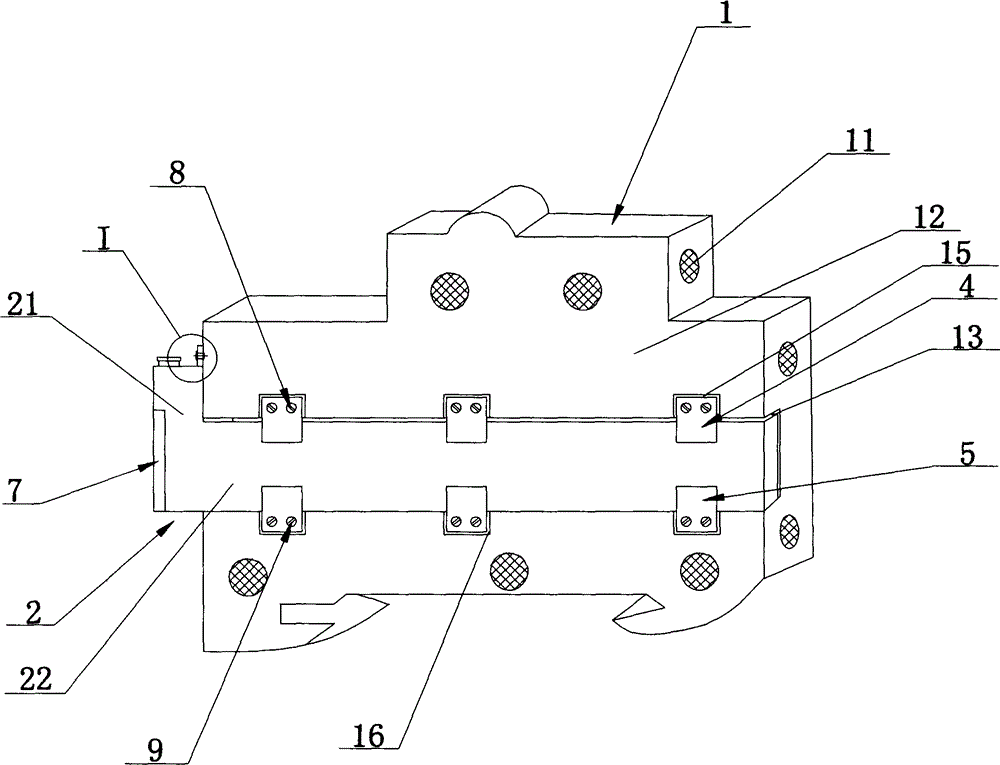

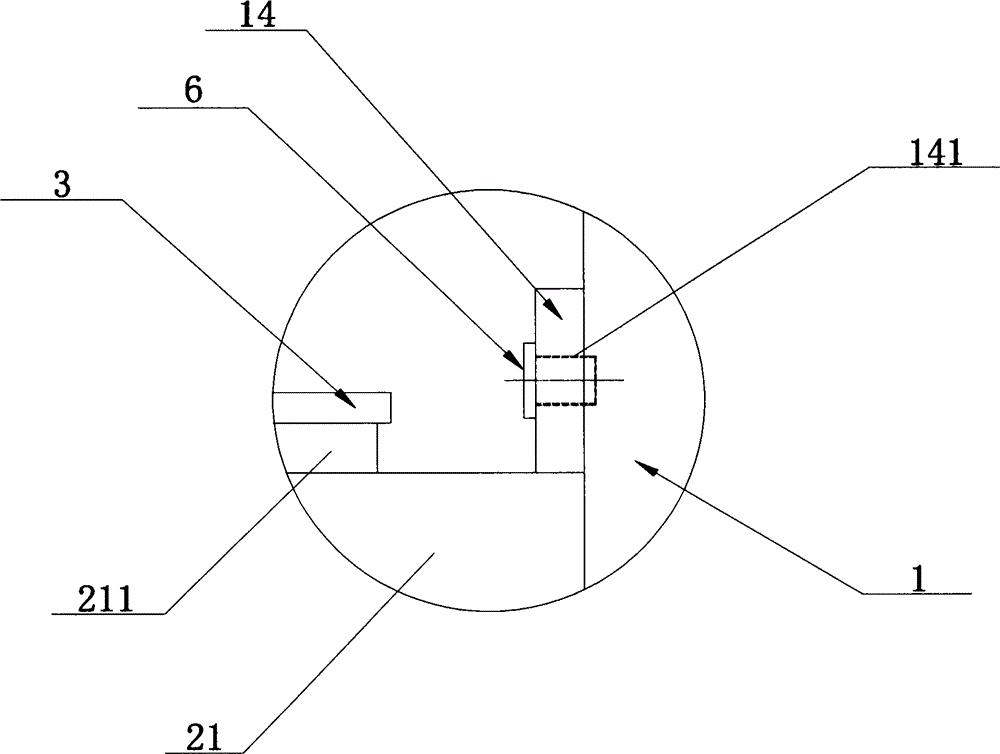

[0018] see figure 1 and figure 2 , a circuit breaker with a water tank disclosed in the present invention, comprising a housing 1, the housing 1 is provided with several heat dissipation holes 11, and the middle part of the splicing surface 12 of the housing 1 is provided with a heat dissipation groove 13, so A water tank 2 is arranged in the heat dissipation groove 13, and the water tank 2 includes a water filling part 21 and a heat dissipation part 22. The water filling part 21 and the heat dissipation part 22 together form an "L" shape structure, and the upper end of the water filling part 21 is provided with a water filling port. 211, the water inlet 211 is threadedly connected with a sealing nut 3, the upper end of the heat dissipation groove 13 is detachably provided with several water tank upper baffles 4, and the lower end of the heat dissipation groove 13 is detachably provided with several water tank lower baffles 5. The upper end of the water filling part 21 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com