Rock soil wetting-drying cycle test device and use method thereof

A dry-wet cycle and test device technology, used in measuring devices, soil material testing, material inspection products, etc., can solve the problems of cumbersome process, difficult to achieve, long dry-wet cycle test period, etc., and achieve precise control of moisture content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

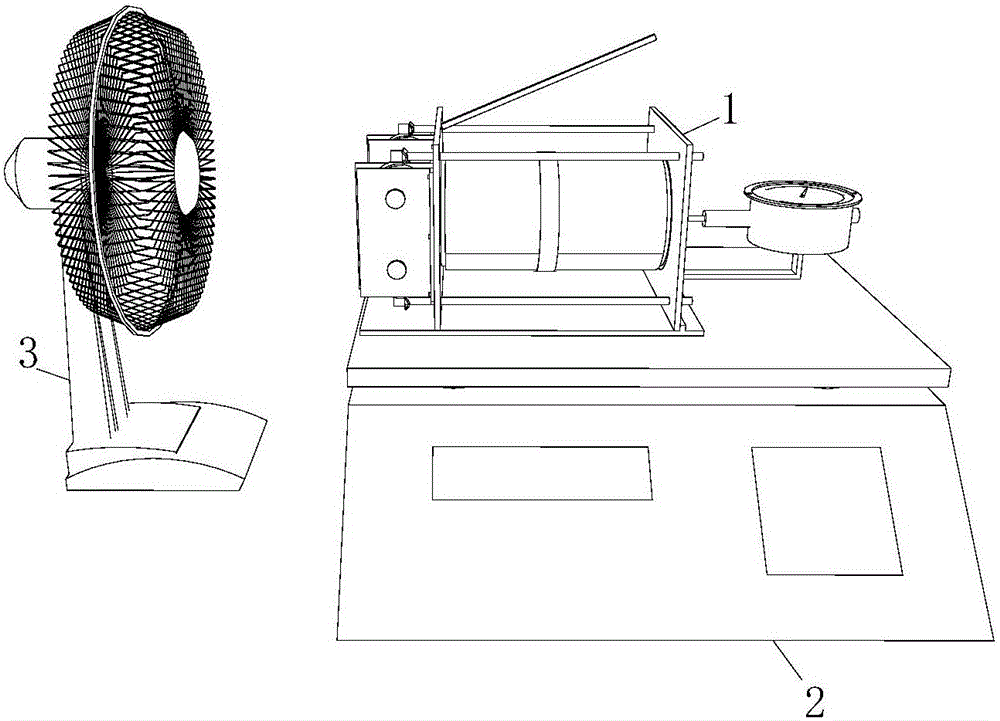

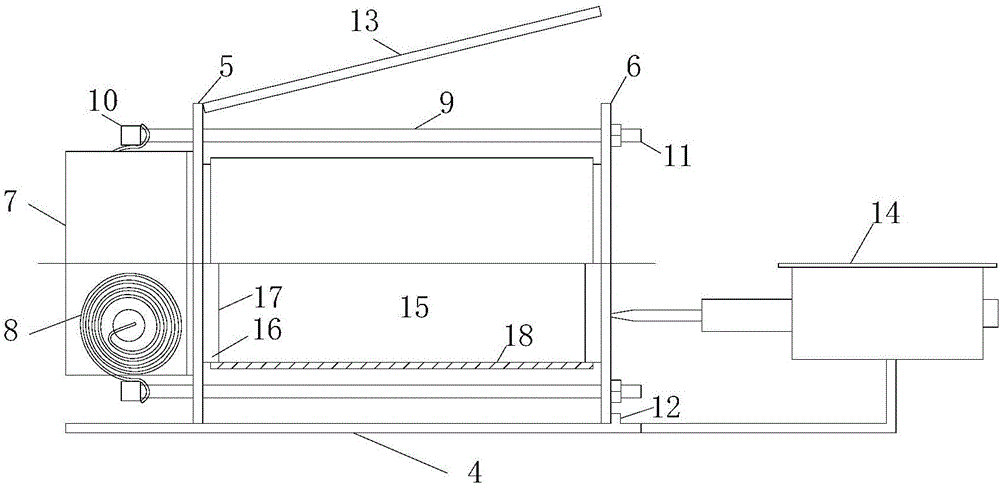

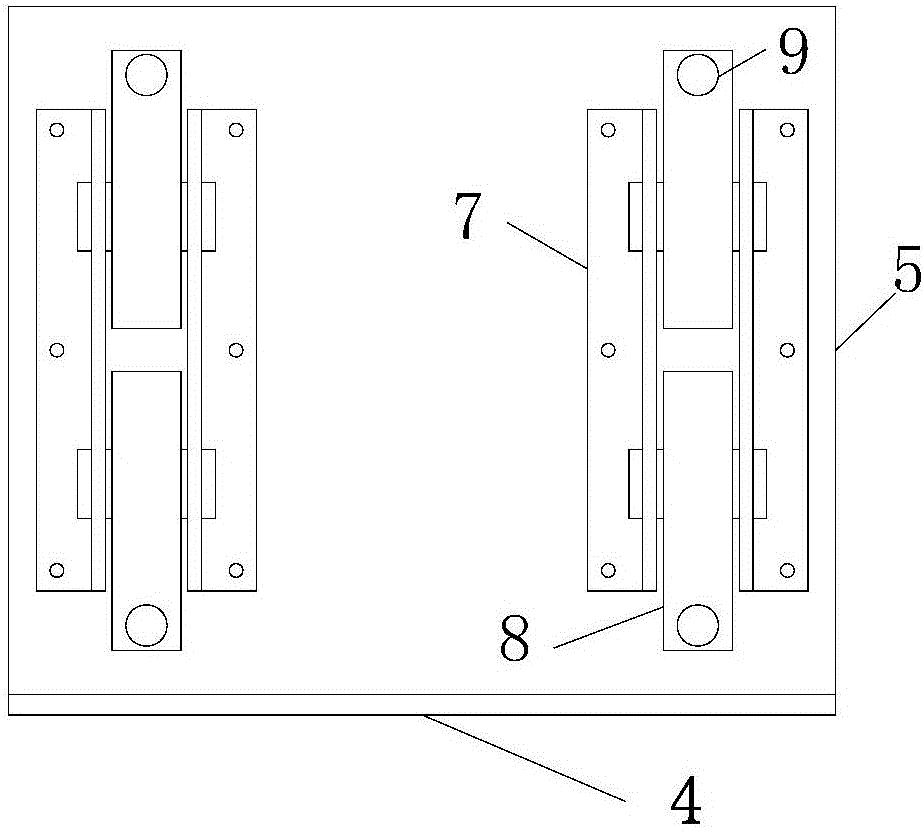

[0036] Such as Figure 1~Figure 7 As shown, a dry-wet cycle test device for rock and soil is composed of a loading device 1 , a weighing device 2 and a heating device 3 . The loading device 1 includes a base 4 , a fixed baffle 5 and a movable baffle 6 , and the movable baffle 6 can move along four pull rods 9 . Two constant force spring supports 7 are welded on the fixed baffle plate 5, and two constant force springs 8 up and down are installed on each constant force spring support 7, and each constant force spring 8 links to each other with a pull rod 9. The two ends of the pull rod 9 are an enlarged end 10 and a bolt-fixed end 11 respectively. Before the test, the sill 12 on the base 4 of the loading device 1 and the pressing bar 13 on the top together play the role of fixing the movable baffle 6 . The fixed baffle 5 is welded and fixed with the base 4, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com