Universal image visual inspection robot

A visual inspection and robot technology, applied in the field of visual inspection, can solve the problems of indeterminate appearance, long inspection time, and low efficiency, and achieve the effects of improving equipment utilization, saving labor, and eliminating missed inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

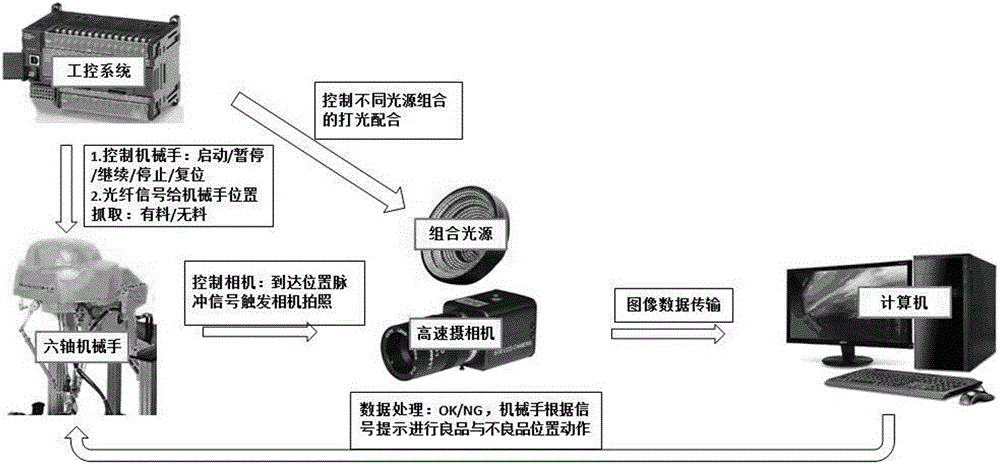

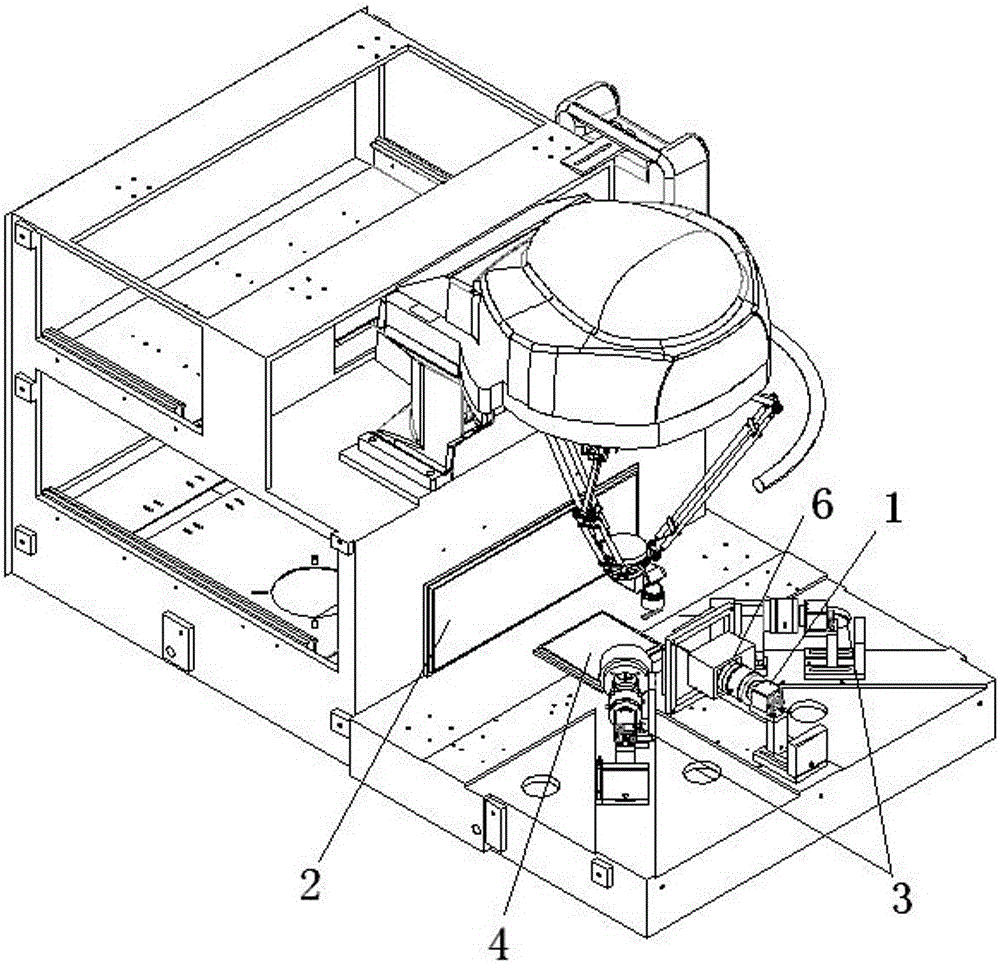

[0023] figure 1 It shows an embodiment of an all-round image vision inspection robot of the present invention, including the following parts installed in the robot body:

[0024] Precision six-axis manipulator: used to pick up or grip parts and perform high-speed full-view rotation and quickly adjust the object distance and depth of field for clear imaging. The repeat positioning accuracy reaches 0.01mm, and the fastest cycle time is 0.3 seconds;

[0025] Combined light source: composed of coaxial light source 1, backlight source 2, ring light source 3, bottom surface light source 4, strip light source 5 and square inclined light source 6, the ring light source 3 is divided into angled ring light source and non-angled ring light source, A selection adjustment device is installed in the combination light source, and different lighting combinations are selected according to different materials, colors, and characteristics of the product to obtain the best lighting effect. For ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com