A hydraulic differential butterfly pump control valve

A differential type, control valve technology, applied in the direction of variable capacity pump components, pump components, valve devices, etc., can solve the problems of low reliability, small opening, uneconomical, etc., to achieve safe protection, short surface spacing, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

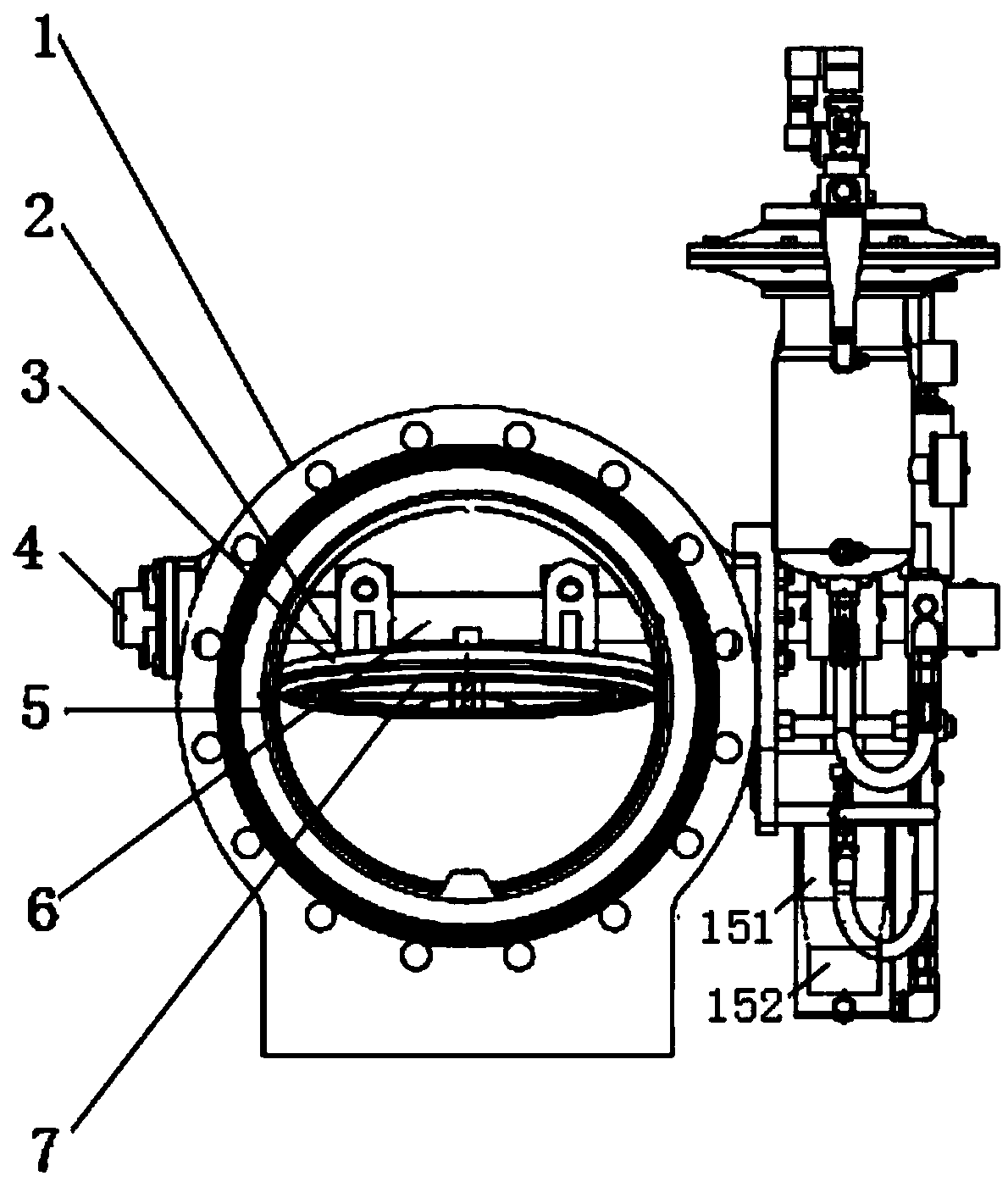

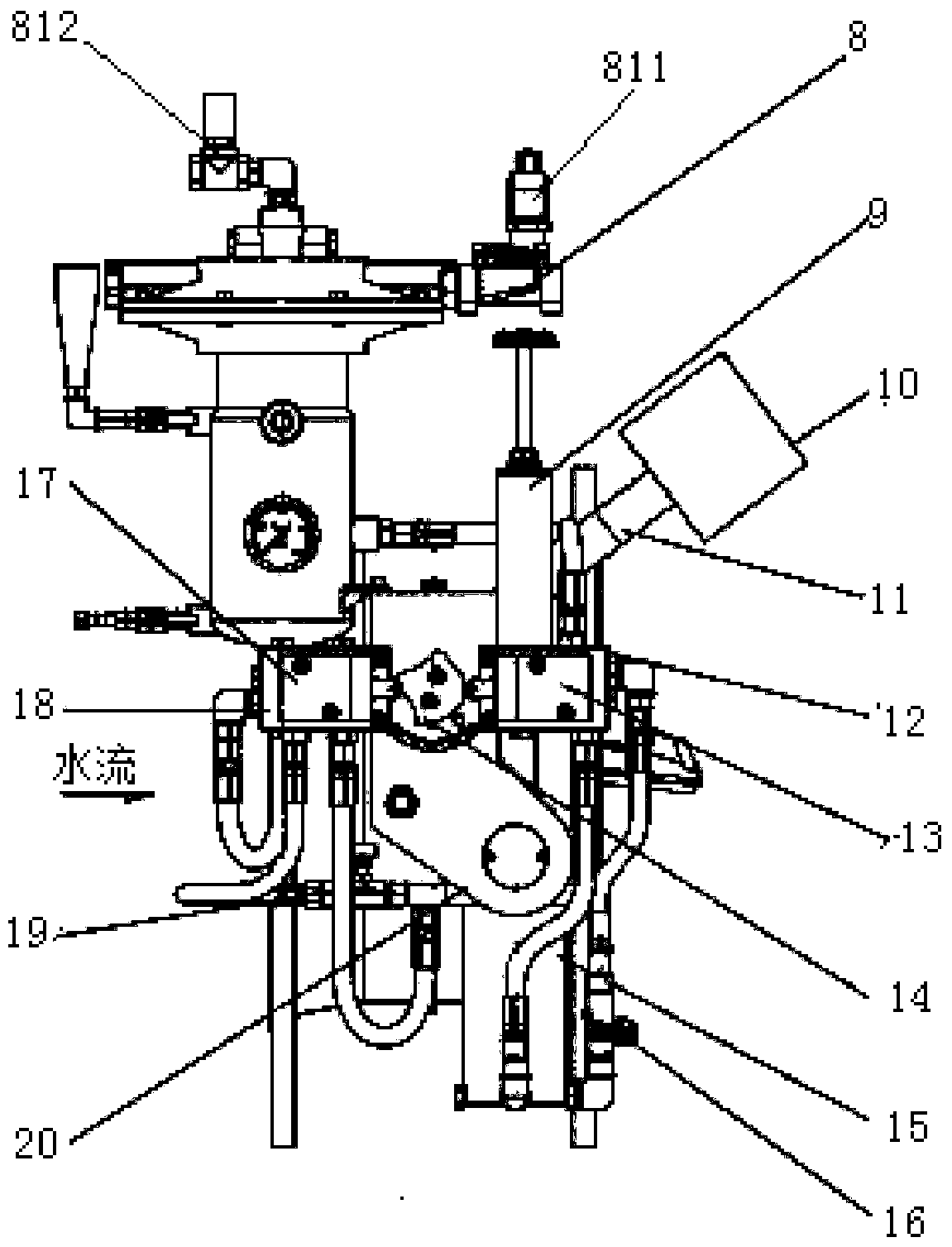

[0048] A hydraulic differential butterfly water pump control valve, such as Figure 1~2 As shown, it includes a valve body assembly, a rocker arm 11 , a buffer cylinder 15 , an oil circuit control assembly and a differential drive assembly 8 .

[0049]The valve body assembly includes a valve body 1, a main shaft 6 arranged on the valve body 1, a butterfly plate 2 arranged in the channel of the valve body 1, a valve seat 5 fixedly connected with the valve body and an end cap group 4, the The valve body assembly adopts an inclined valve seat design, a large eccentric integral structure, and is equipped with fully open and fully closed limits. The butterfly plate 2 is a swash plate butterfly valve disc, on which a sealing ring 3 is arranged, and the sealing ring 3 is fixed on the outer edge of the butterfly plate 2 through the pressure plate 7, and the pressure plate 7 is used to make the The sealing ring 3 is easy to replace, the butterfly plate 2 is suspended on the main shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com